Rare earth magnesium alloy welding wire and preparation method thereof

A technology of alloy welding wire and rare earth magnesium, which is applied in the field of magnesium alloys and can solve problems such as inability to achieve metallurgical bonding, inability to form wire coils, and broken wires

Active Publication Date: 2021-06-25

CHINA WEAPON SCI ACADEMY NINGBO BRANCH

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Unlike aluminum alloys, the connection joints of magnesium alloy extruded wires are "false connections", which cannot achieve met

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

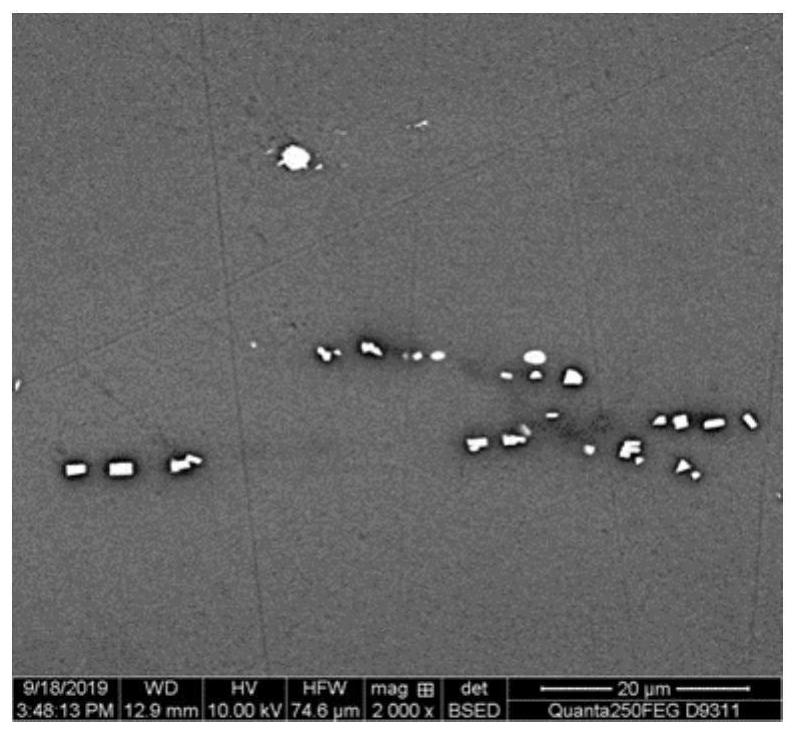

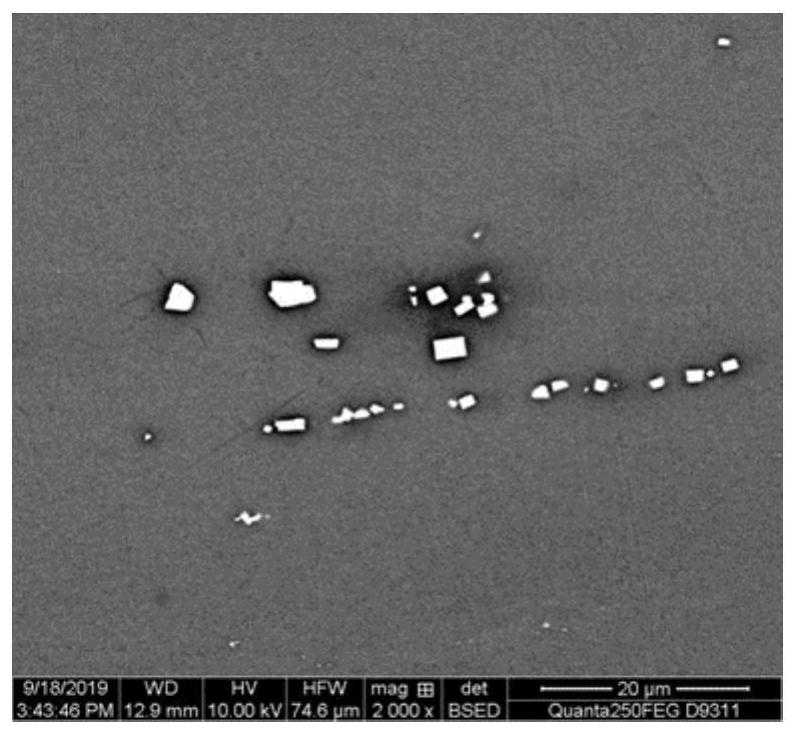

The invention discloses a rare earth magnesium alloy welding wire. The rare earth magnesium alloy welding wire is characterized by comprising 2.00-7.00 wt% of Gd, 0.02-2.00 wt% of Y, 0.30-0.80 wt% of Zr, 0.20-0.50 wt% of Sn, 0.02-0.18 wt% of Ag, 0.02-0.18 wt% of Er and the balance magnesium and inevitable impurities. According to the rare earth magnesium alloy welding wire, an Mg-Gd-Y-Zr alloy system capable of being strengthened through heat treatment is selected, and microalloy elements the Gd, the Y, the Zr, the Ag and the Sn are cooperatively added, so that the melt quality is improved, the welding wire quality is improved, and the defects of pore oxide inclusion and the like in a welding joint are reduced; the starting difficulty of a conical surface slippage system is reduced, the plastic deformation capacity of an alloy material is greatly improved by starting a potential slippage system, the extrusion deformation process of a welding wire is coordinated, and the welding wire quality is improved; and low-scale second-phase particles serve as heterogeneous nucleation factors, so that grains are refined, the alloy grain size is controlled, and the extrusion deformation capacity of the material is improved.

Description

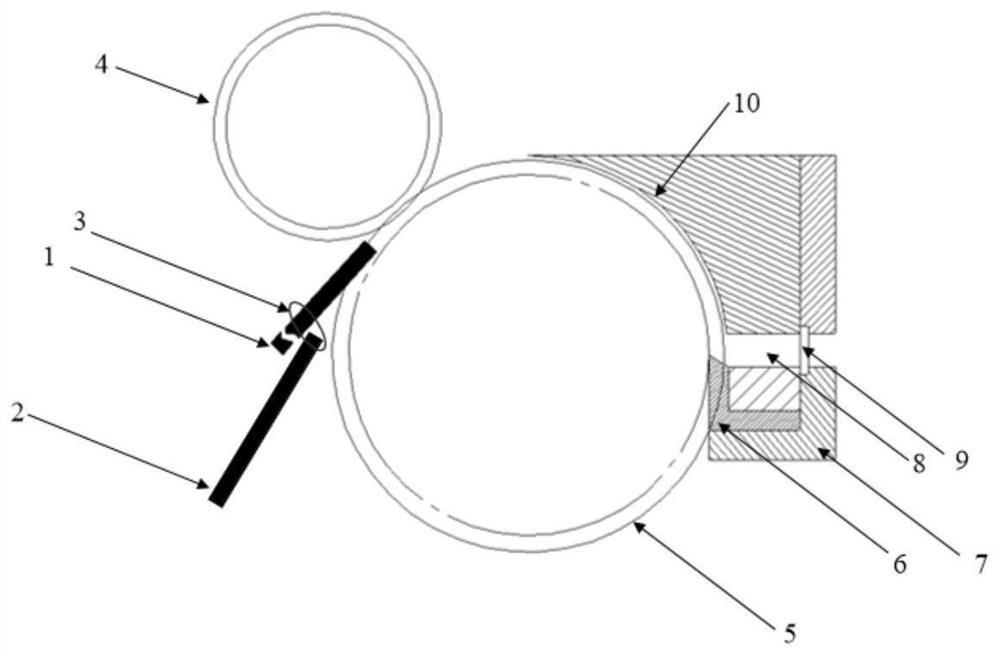

technical field [0001] The invention relates to magnesium alloys, in particular to a rare earth magnesium alloy welding wire and a preparation method thereof. Background technique [0002] With the characteristics of low density, high specific strength and high specific stiffness, magnesium alloys are widely used in the fields of aerospace and transportation electronics. The demand for magnesium alloys is increasing, and the types of magnesium alloy materials are also increasing. [0003] At present, the connection method of magnesium alloy components with large size and complex structure mostly adopts welding method. However, the development of magnesium alloy welding wire materials is far behind that of magnesium alloy materials. This is because the processing method of industrial and semi-industrial magnesium alloy welding wire for magnesium alloy welding is extrusion processing. The close-packed hexagonal structure of magnesium alloys leads to high deformation resistanc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/28B23K35/40C22C23/06C22F1/06

CPCB23K35/284B23K35/40C22C23/06C22F1/06

Inventor 周古昕李金宝郎玉婧王生杜秀征韩峰毛华乔丽李清波郑军贺新民

Owner CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com