In-field three-rail transport vehicle

A three-track, transport vehicle technology, used in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of frequent contact of finished pigs, slow walking speed, and difficulty in ensuring the safety and quality of finished pigs. Improve biosafety level and realize the effect of unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

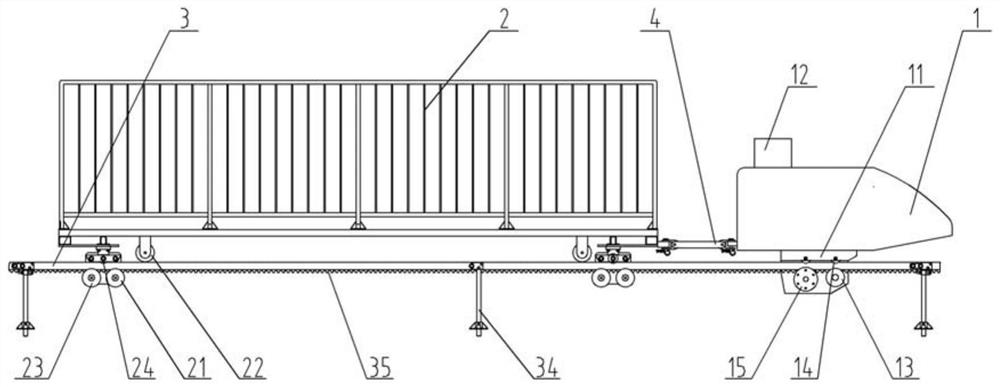

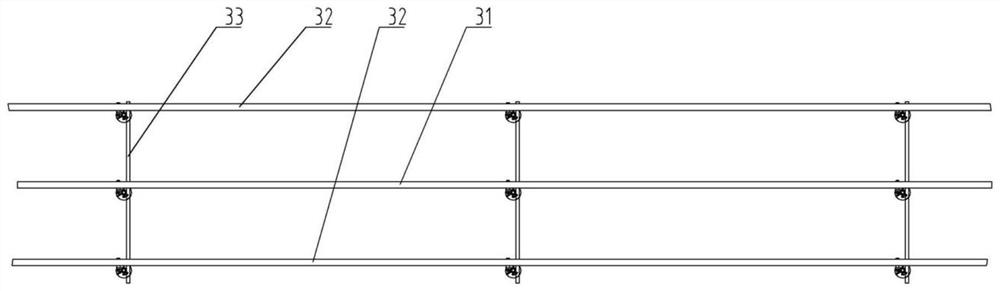

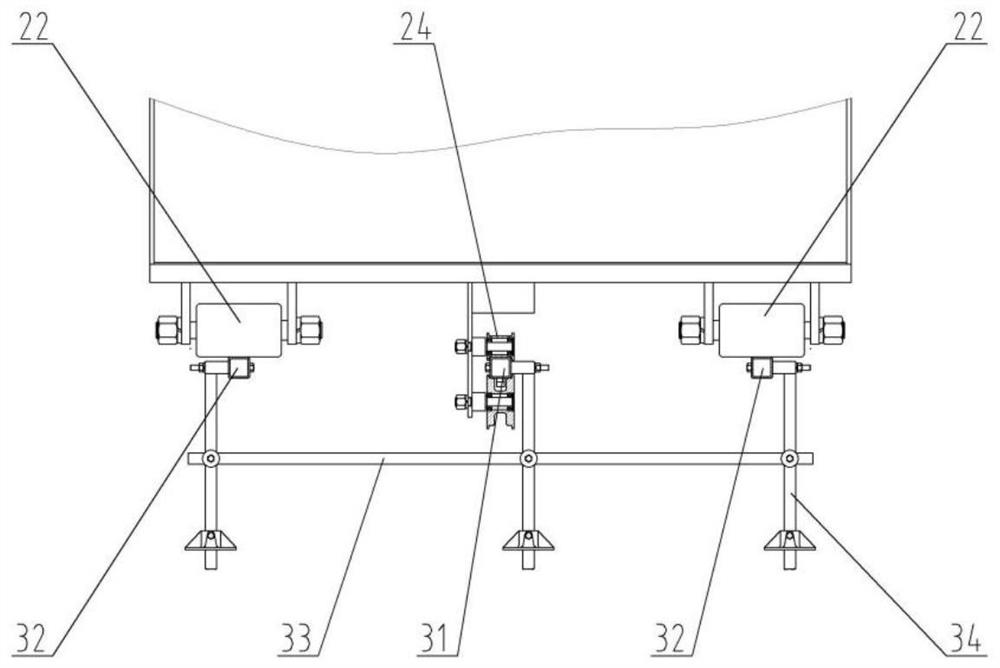

[0035] Please refer to Figure 1 to Figure 3 As shown, a three-track transport vehicle in the field includes a running track 3, a head 1, a driving device 11, a compartment 2, a braking device 23, a load wheel 22 and a control device 12; The main track 31 and two auxiliary tracks 32 arranged in parallel, the main track 31 is arranged between the two auxiliary tracks 32, the lower end of the main track 31 is arranged along the length direction of the main track 31 There is a continuous rack 35; the machine head 1 is arranged on the length direction of the main track 31 through the driving device 11, and the driving device 11 is engaged with the rack 35;

[0036] The compartment 2 is arranged above the running track 3, and the compartment 2 is connected to the machine head 1 through a universal joint 4. The compartment 2 is a rectangular parallelepiped steel structure compartment, and the side wall of the compartment 2 A square grid is arranged on the bottom surface of the encl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com