Method for improving strength of Fe-Mn-Al-C series low-density steel

A fe-mn-al-c, low-density steel technology, which is applied in the field of improving the strength of Fe-Mn-Al-C series low-density steel, can solve the problems of further improvement, improvement, and time-consuming problems that are difficult to further improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for improving the strength of Fe-Mn-Al-C series low-density steel, the steps of the method are as follows:

[0030] (1) The Fe-Mn-Al-C steel piece corresponding to No. 1 in Table 1 is subjected to a solution treatment of soaking and heat preservation for 1 hour at 950°C to obtain the Fe-Mn-Al-C steel after solution treatment ;

[0031] (2) The Fe-Mn-Al-C series steel after the solution treatment is rolled out of the furnace, the downforce is 60%, and the final rolling temperature is 550 ° C. After the rolling is completed, it is immediately quenched into water and cooled to room temperature to obtain Fe-Mn-Al-C series steel after rolling;

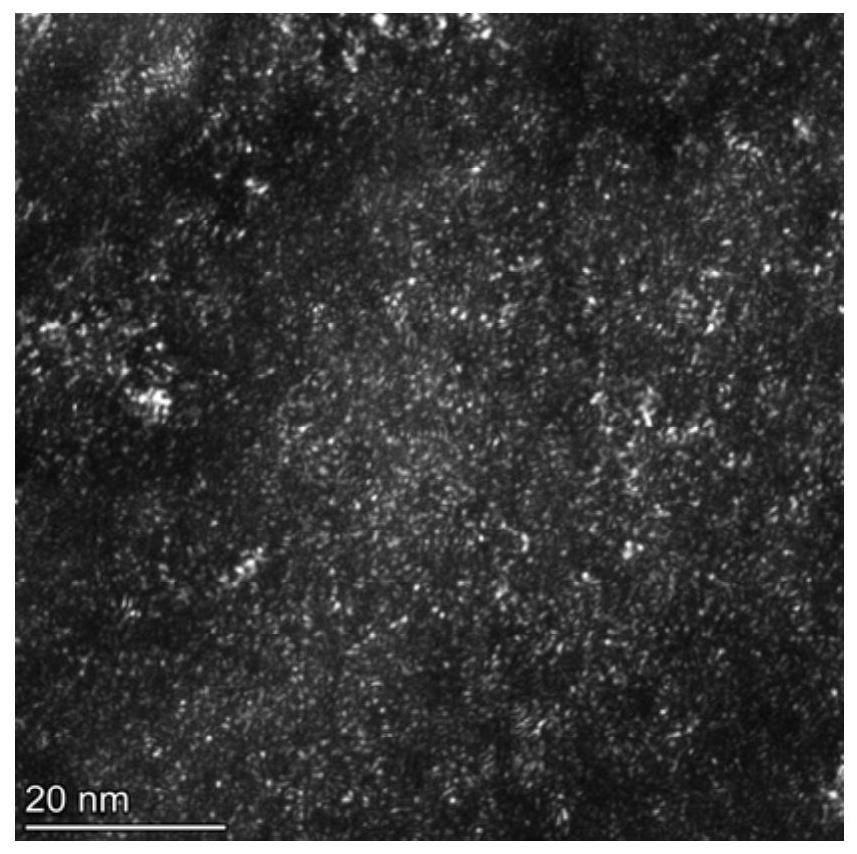

[0032] (3) The rolled Fe-Mn-Al-C steel is subjected to aging treatment at 600°C for 2 hours, and after the aging treatment is completed, it is cooled to room temperature in the air to obtain a low-density and high-strength Fe-Mn- Al-C series steel blank.

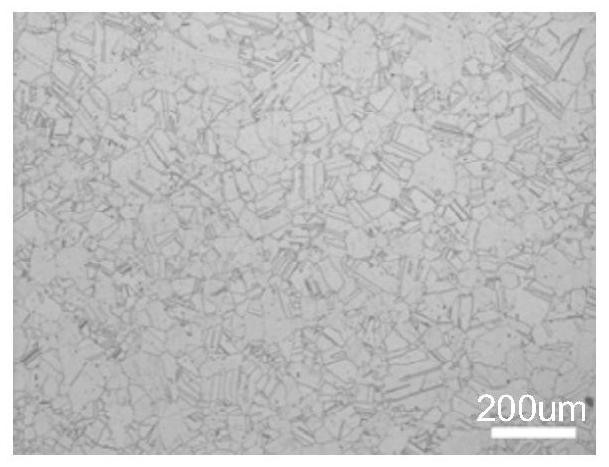

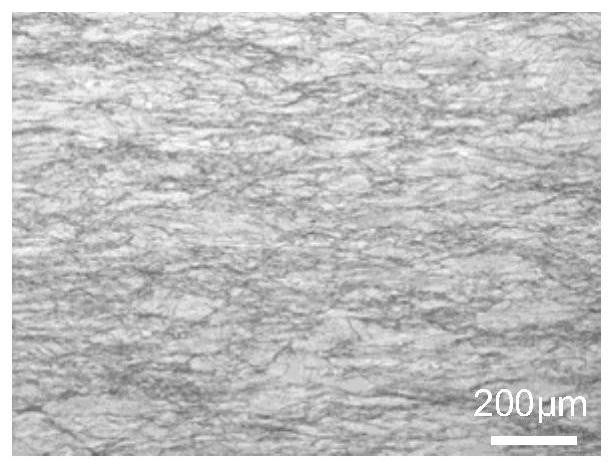

[0033] The OM test results of the Fe-Mn-Al-C series steel after th...

Embodiment 2

[0036] A method for improving the strength of Fe-Mn-Al-C series low-density steel, the steps of the method are as follows:

[0037] (1) The Fe-Mn-Al-C series steel corresponding to No. 2 in Table 1 is subjected to a solution treatment of soaking and heat preservation for 3 hours at 950° C. to obtain the Fe-Mn-Al-C series steel after the solution treatment;

[0038] (2) The Fe-Mn-Al-C series steel after the solution treatment is rolled out of the furnace, the downdraft is 40%, the final rolling temperature is 650 ° C, and immediately quenched into water to cool to room temperature after rolling, to obtain Fe-Mn-Al-C series steel after rolling;

[0039] (3) The rolled Fe-Mn-Al-C steel is aged at 550°C for 1 hour, and then cooled to room temperature in air to obtain a low-density, high-strength Fe-Mn-Al- C series steel blank.

[0040] The OM test results of the Fe-Mn-Al-C series steel after the solution treatment and the OM test results of the rolled Fe-Mn-Al-C series steel sho...

Embodiment 3

[0043] A method for improving the strength of Fe-Mn-Al-C series low-density steel, the steps of the method are as follows:

[0044] (1) The Fe-Mn-Al-C series steel corresponding to No. 3 in Table 1 is subjected to solution treatment by soaking at 1100°C for 2 hours to obtain the Fe-Mn-Al-C series steel after solution treatment ;

[0045] (2) The Fe-Mn-Al-C series steel after the solution treatment is rolled out of the furnace, the downdraft is 50%, and the final rolling temperature is 700 ° C. After the rolling is completed, it is immediately quenched into water and cooled to room temperature to obtain Fe-Mn-Al-C series steel after rolling;

[0046](3) The rolled Fe-Mn-Al-C steel is aged at 550°C for 2 hours, and then cooled to room temperature in the air to obtain a low-density high-strength Fe-Mn-Al- C series steel blank.

[0047] The OM test results of the Fe-Mn-Al-C series steel after the solution treatment and the OM test results of the rolled Fe-Mn-Al-C series steel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com