Device and method for integrity detection of cast-in-situ piles based on densely distributed fiber grating temperature sensing technology

A distributed optical fiber and integrity detection technology, which is applied in infrastructure testing, infrastructure engineering, construction, etc., can solve the problem of low accuracy of small-scale defect detection, the inability to guarantee the survival rate of sensors, and prolong the detection time of pile foundations and other problems to achieve the effect of reducing the interference of pile foundation detection, overcoming inaccurate judgments, and reducing measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

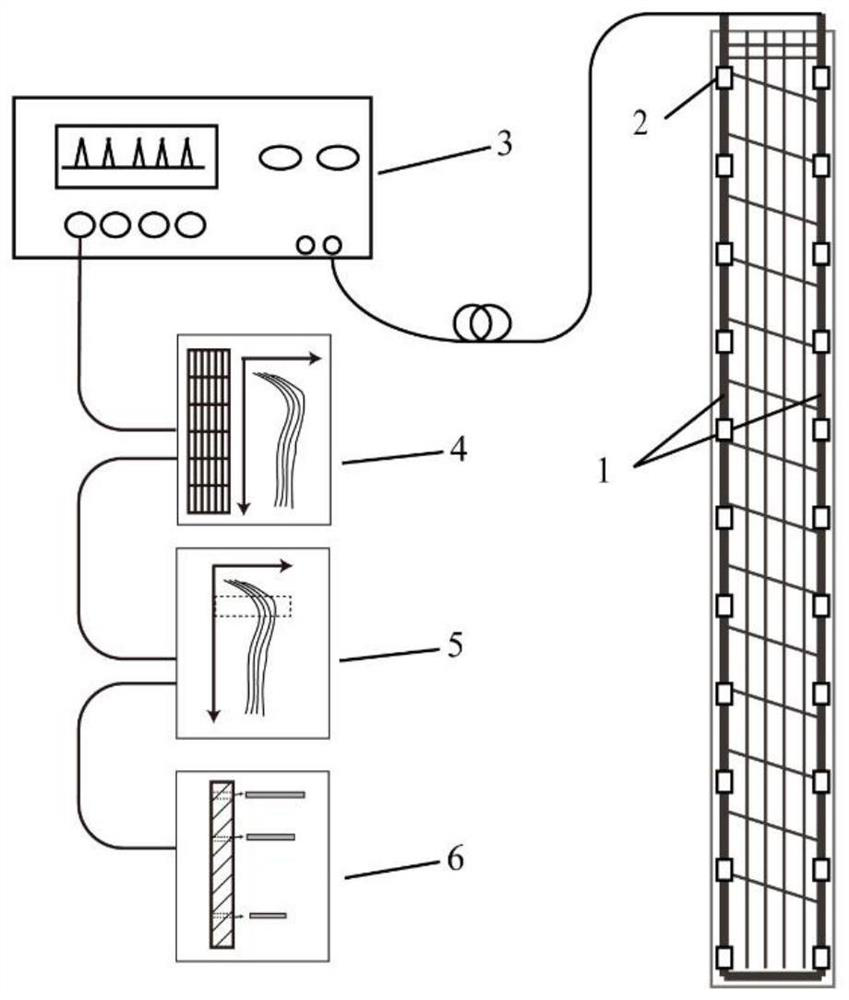

[0063] Such as figure 1 As shown, the integrity detection device and method for cast-in-situ piles based on densely distributed fiber Bragg grating temperature sensing technology includes: armored densely distributed fiber Bragg grating temperature sensing optical fiber 1, temperature sensitization unit 2, and densely distributed temperature demodulator 3. Temperature data processing unit 4, defect analysis unit 5 and pile foundation integrity evaluation unit 6;

[0064] A device and method for detecting the integrity of cast-in-situ piles based on densely distributed fiber grating temperature sensing technology, comprising the following steps:

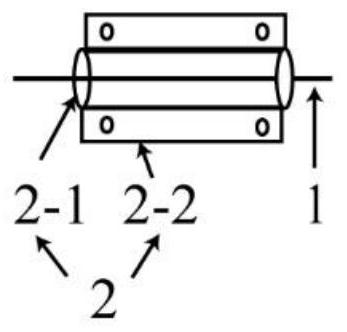

[0065] Step one, such as figure 2 As shown in Fig. 1, the protective outer layer of the armored dense distributed fiber Bragg grating temperature sensing fiber was peeled off at a certain distance, and the temperature-sensitizing element was adhered to the armored dense distributed fiber Bragg grating temperature sensing fiber ring ...

Embodiment 2

[0073] A device and method for detecting the integrity of cast-in-situ piles based on densely distributed fiber Bragg grating temperature sensing technology, which is characterized in that it includes: armored densely distributed fiber Bragg grating temperature sensing optical fiber 1, temperature-sensitizing unit 2, densely distributed temperature Demodulator 3, temperature data processing unit 4, defect analysis unit 5 and pile foundation integrity evaluation unit 6; It consists of a temperature-sensitizing element 2-1 and a metal protective layer 2-2; the armored densely distributed optical fiber grating temperature sensing optical fiber 1 is fixedly bound on the main reinforcement of the steel cage; the armored densely distributed optical fiber grating temperature sensing optical fiber 1 Connect with the densely distributed temperature demodulator 3; the densely distributed temperature demodulator 3 collects temperature data and transmits it to the temperature data processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com