Supercharger volute flow channel volute tongue to reference hole center inspection tool and detection method

A reference hole and supercharger technology, which is applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of low detection efficiency, achieve the effects of simple operation, reduce bad outflow, and increase detection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

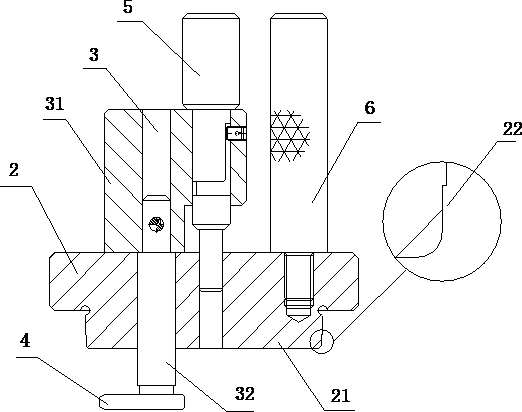

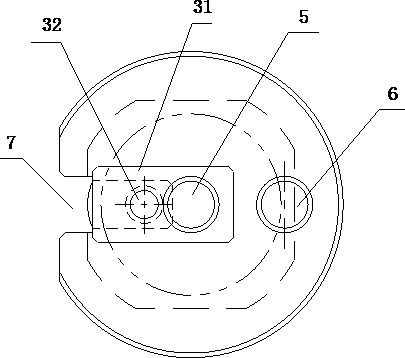

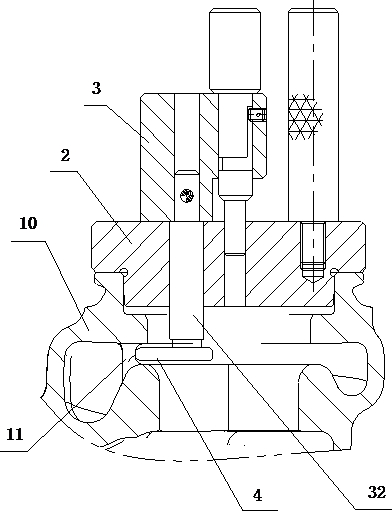

[0018] Embodiment one: if figure 2 image 3 As shown, a supercharger volute channel volute tongue 11 to the center of the reference hole inspection tool, including a positioning block 2, the bottom of the positioning block 2 forms an insertion block 21, and the insertion block 21 and the bottom surface of the positioning block 2 An assembly step is formed, and the assembly step is suitable for matching with the reference end surface A of the volute and the reference aperture B; and a horizontal rotation mechanism 3 and a measuring head 4, the measuring head 4 is connected with the positioning block 2 through the horizontal rotation mechanism 3, and the The measuring head 4 is located below the positioning block 2, and the horizontal rotation mechanism 3 drives the measuring head 4 to rotate to adjust the distance between the front edge of the measuring head 4 and the center of the reference hole to be the maximum value; that is, the measuring head 4 is adjusted to detect pos...

Embodiment 2

[0029] Embodiment two: if Figure 4 As shown, a supercharger volute channel volute tongue 11 to the center of the reference hole detection method, using the inspection tool of embodiment 1; including the following steps: Step S01, first pull out the limit pin 5 in the inspection tool, At this time, the probe 4 is in a movable state, rotate the probe 4 about 90°, so that it can be put into the volute without interference; step S02, use the positioning block 2 to paste the reference end surface A of the volute, and insert the block 21 at the bottom Cooperate with the reference aperture B for positioning, visually observe the position of the volute tongue 11 through the observation slot 7, and put it into the volute; step S03, then turn the probe 4 back to its original position, insert the limit pin 5 into the pin hole, and insert the probe 4 Fix at the detection position of the inspection tool; step S04, rotate the entire inspection tool, and when the probe 4 passes the tongue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com