A photoelectric multi-channel communication pipe liquid level bridge deflection measurement device and method

A technology of bridge deflection and measurement method, which is applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc., can solve the problems of low accuracy of deflection detection system, disappearance of liquid level edge line, easy to be disturbed by the environment, etc. To achieve the effect of convenient installation, improved accuracy and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

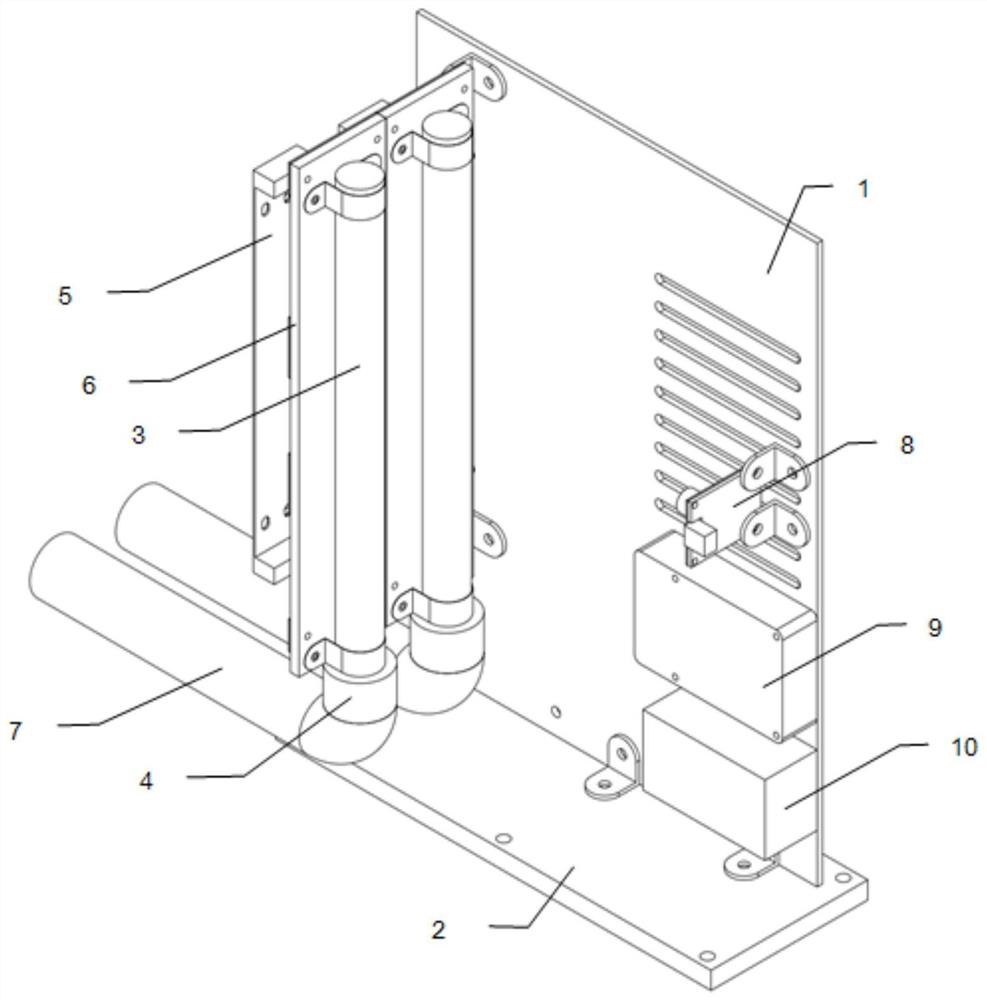

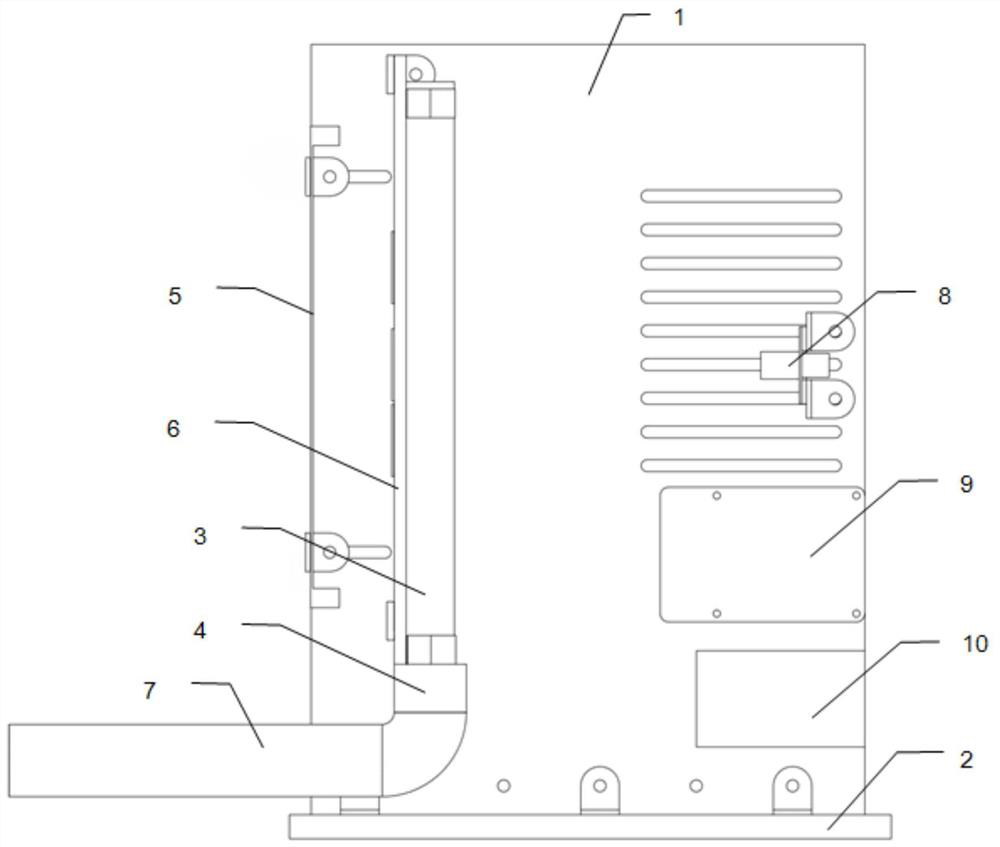

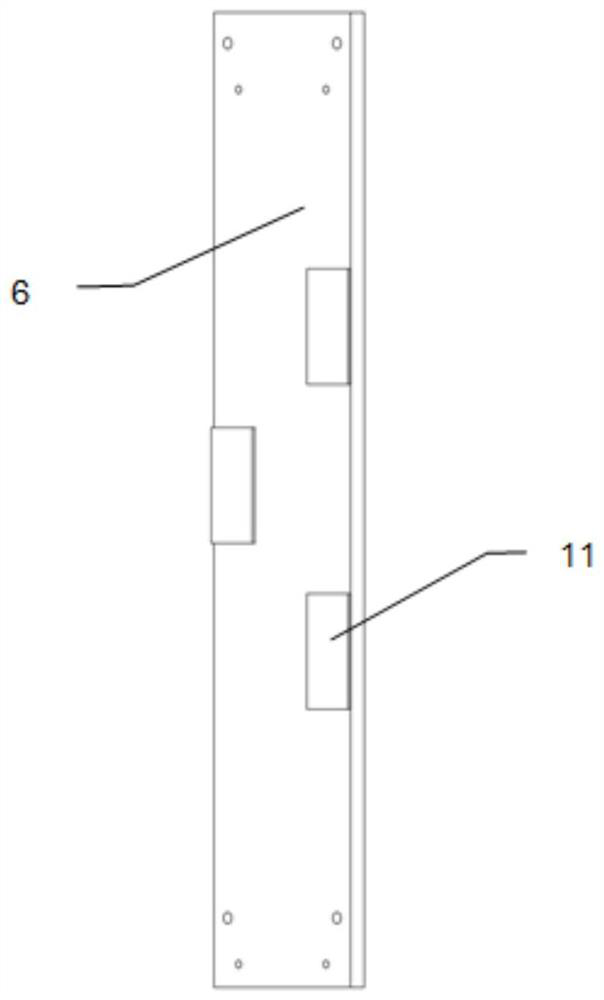

[0049] A photoelectric multi-channel connecting pipe liquid level bridge deflection measuring device, such as figure 1 As shown, it includes a base 2, a fixed plate 1, a power supply 10, a light source 5, a horizontal connecting pipe 7, a liquid level observation pipe 3, a connecting pipe joint 4, a diffuser plate 6, a visual sensor 8, and a digital processing unit 9;

[0050] The light source 5 used in this embodiment is a bar-shaped light source and is a white light source; the fixed plate 1 has a plurality of horizontal chutes, which are used to adjust the shooting distance and height, and adapt to different measurement ranges; the digital processing unit 9 is a computer;

[0051] The plane where the base 2 is located is a horizontal plane, the fixed plate 1 is vertically installed on the base 2, and the horizontal connecting pipe 7 is a connecting pipe parallel to the base 2 and connected from the outside. The joint 4 is connected with two liquid level observation tubes 3,...

Embodiment 2

[0060] A device and method for calibrating a photoelectric multi-channel communication pipe liquid level bridge deflection measuring device constructed in Example 1, such as Figure 5 As shown, prepare lifting slide table, laser displacement meter 20, laser baffle 22, digital-analog acquisition card 21; and light source 5, astigmatism plate 6, liquid level observation tube 3, visual sensor 8, digital processing unit 9, power supply 10 all Same as embodiment 1;

[0061] In the application of bridge deflection measurement, a measurement accuracy of 0.1 mm can meet the measurement requirements. The accuracy of the laser displacement meter used in this embodiment is at the micron level, which can meet the calibration requirements with higher accuracy.

[0062] The calibration method includes the following steps,

[0063] S21, fix the liquid level of the liquid level observation tube 3 so that the liquid level is on the same level as the reference position of embodiment 1, and the...

Embodiment 3

[0072] After the calibration method described in Example 2 is used to calibrate the photoelectric multi-channel communication pipe liquid level bridge deflection measurement device constructed in Example 1, the device and method for verifying and calibrating the calibration results, such as Image 6 As shown, prepare horizontal fixed plate 12, syringe, ball screw, stepper motor 16, pipe channel sealing interface 15, conduit 14; there is a cavity in the described tube channel sealing interface 15; light source 5, astigmatism plate 6, visual sensor 8. The digital processing unit and the power supply are the same as in Embodiment 1; the bottom of the liquid level observation tube 3 does not need to be connected to the horizontal connecting pipe 7, but to take over the channel sealing interface 15;

[0073] The method of verification and calibration includes the following steps:

[0074] S31, fix the position of the visual sensor at the reference position in embodiment 1, inject a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com