Component carrier manufacturing method, processing system, computer program and system architecture

A technology of component loading and semi-finished products, applied in the field of system architecture, can solve problems such as system false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The illustrations in the figures are schematic. It should be noted that in different figures, similar or identical elements or features are provided with the same reference signs or with reference signs that differ from the corresponding reference signs only within the first digit . In order to avoid unnecessary repetition, elements or features that have already been explained with respect to the previously described embodiments will not be described in detail later in this specification.

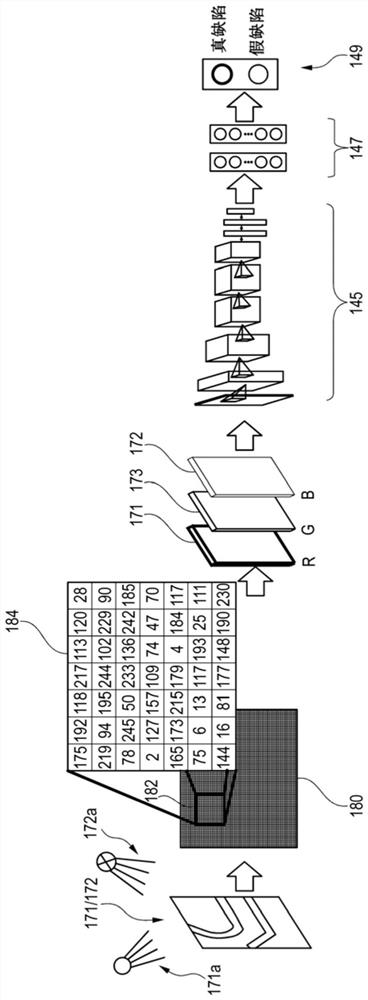

[0094] figure 1 Algorithms are shown for AI processing of AOI captured images to identify false defects that have been detected by undelineated AOI devices on the surface of a semi-finished part carrier. The described algorithm relying on AOI defect detection can be executed for each layer of the multi-layer component carrier. Such a multilayer component carrier can be formed by sequentially laminating an electrically conductive layer structure and an electrically insulating layer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap