Suspension type cargo carrying machine

A hanging and cargo technology, which is applied in the direction of walking bridge cranes, cranes, walking mechanisms, etc., can solve the problems of inconvenient cargo observation and detection, low efficiency of manual cargo handling, and cargo shaking and falling, etc., to achieve convenient transportation distance, Easy to observe, detect and adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

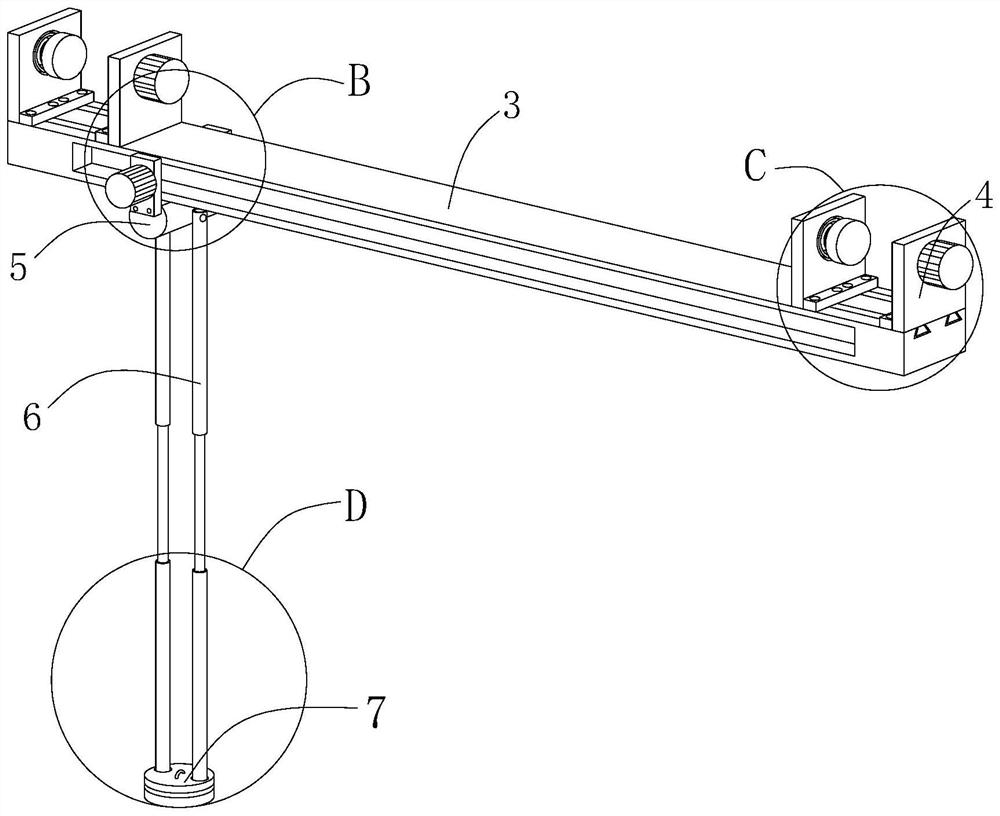

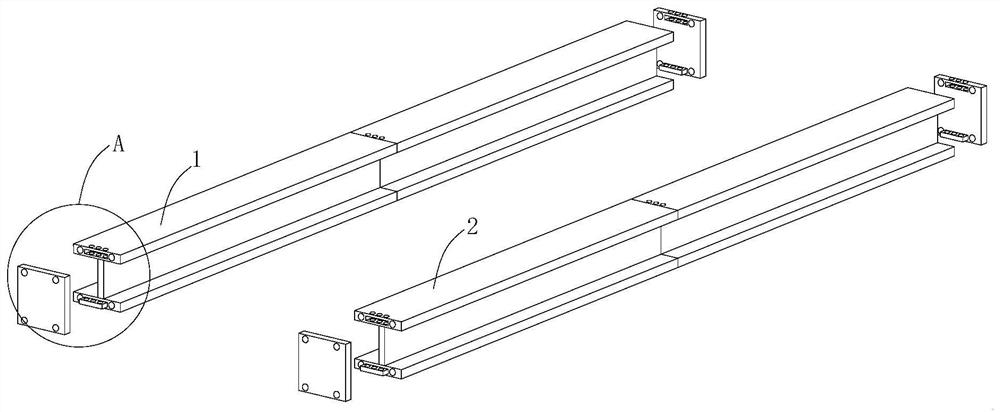

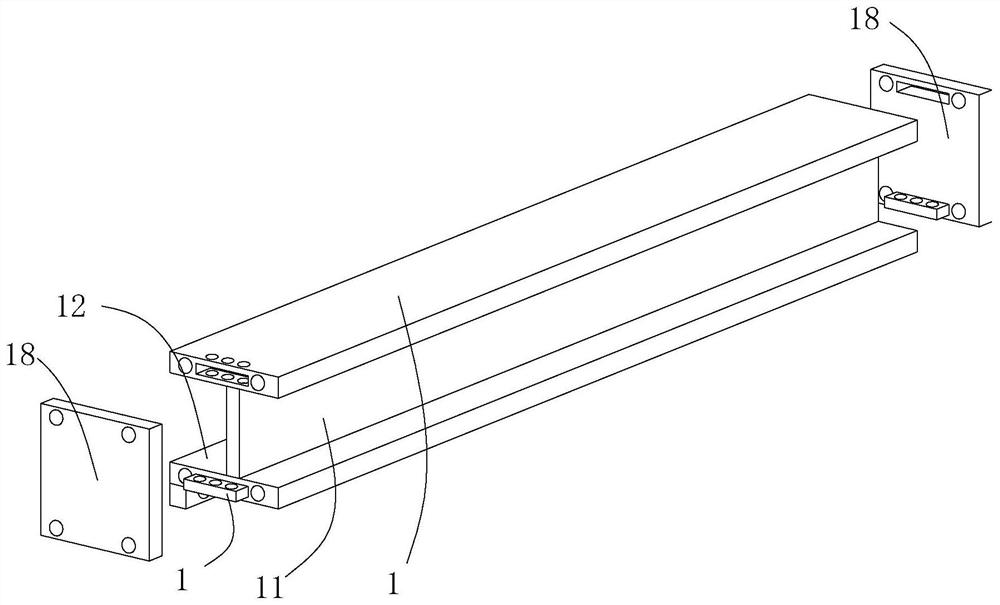

[0040] Specific embodiments: before use, two sets of first horizontal plates 1 are connected end to end, so that the first assembly groove 14 on the rear surface of the first horizontal plate 1 is assembled with the first assembly groove 14 on the front surface of the second set of first horizontal plates 1 . The plates 16 are connected, and the first assembly plate 16 on the rear surface of the first horizontal plate 1 is connected to the first assembly groove 14 on the front surface of the second group of first horizontal plates 1. At this time, the first bolts 131 and the second bolts 162 are respectively It is fixed in the corresponding first assembly hole 13 and the second assembly hole 161, so that the first assembly plate 16 is fixed in the corresponding first assembly groove 14, realizing the splicing of two sets of first horizontal plates 1, which is convenient for increasing the The carrying distance of the goods, then the first baffle 17 and the second baffle 18 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com