Positioning crystal flashing effect ceramic tile and preparation method thereof

A technology for ceramic tiles and flash-drying, which is applied in the field of positioning crystal flashing effect ceramic tiles and its preparation. It can solve the problems of ceramic tiles such as poor decorative effect and performance, glaze collapse, cracks, etc., and achieve good positioning crystal flashing effect and high water absorption rate. Up to standard, good effect of antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

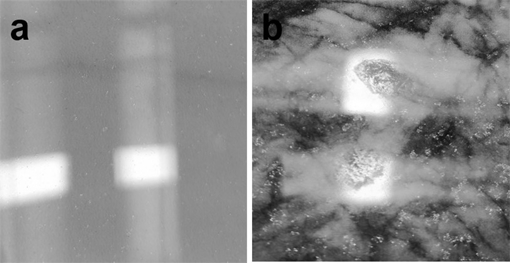

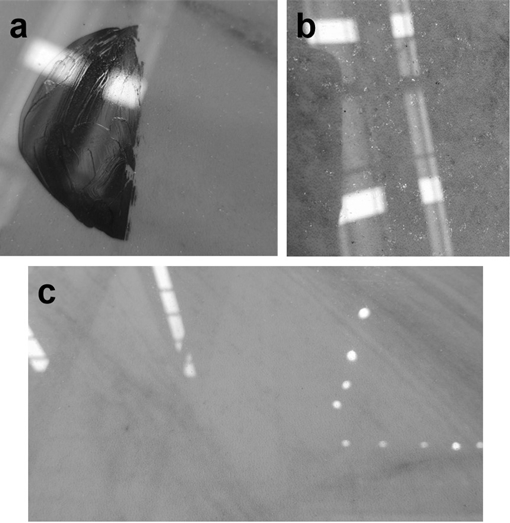

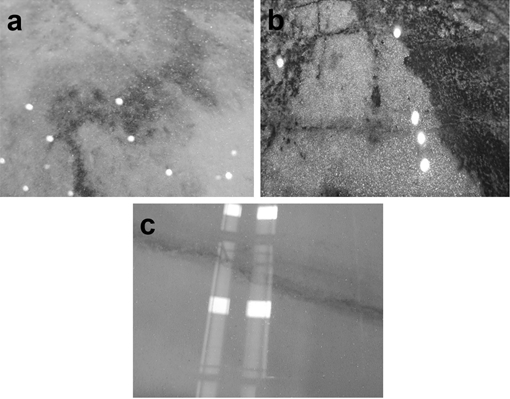

Image

Examples

preparation example Construction

[0056] The present application also provides a preparation method for the ceramic tile with the above positioning crystal flash effect, which specifically includes: sequentially applying top glaze on the surface of the brick, performing pattern decoration, digital inkjet glue ink according to the designed texture, and positioning the first crystal flash dry particle mixture 1. Set the surface glaze layer, and then put the bricks into the kiln for firing, polishing, and edge grinding, and then the ceramic tiles with positioning crystal flash effect can be obtained.

[0057] Wherein, the green body is made by pressing common green body powder and then drying. The raw materials for preparing the green body are common substances in the industry. In parts by weight, the raw materials for the green body include: water-milled potassium stone powder: 4-6 parts, water-milled potassium-sodium stone powder: 11-13 parts, Jiangxi sodium sand: 7 parts Parts~8 parts, bauxite: 3 parts~5 parts...

Embodiment 1

[0071] The positioning crystal flash effect ceramic tile of this embodiment is prepared by the following preparation methods, including:

[0072] (1) Press and shape the green body powder, and dry it to make bricks;

[0073] (2) Spread glaze on the surface of the brick adobe, carry out pattern decoration, and digitally inkjet glue ink according to the design texture;

[0074] (3) Positioning and distributing the first crystal flash dry particle mixture including crystal flash dry particles and primary burnt dry particles on the surface of the adobe, and absorbing the excess mixture with a suction device;

[0075] In this step, the chemical composition of crystal flash dry particles is calculated by weight percentage, including: ZrO 2 : 3%, SiO 2 : 68%, Al 2 o 3 : 3%, B 2 o 3 : 14%, Na 2 O: 10%, Li 2 O: 2%; the chemical composition of the once-burned dry grain is calculated by weight percentage, including: SiO 2 : 56%, Al2 o 3 : 10%, CaO: 12%, MgO: 2%, ZnO: 10%, BaO: ...

Embodiment 2

[0080] The positioning crystal flash effect ceramic tile of this embodiment is prepared by the following preparation methods, including:

[0081] (1) Press and shape the green body powder, and dry it to make bricks;

[0082] (2) Spread glaze on the surface of the brick adobe, carry out pattern decoration, and digitally inkjet glue ink according to the design texture;

[0083] (3) Positioning and distributing the first crystal flash dry particle mixture including crystal flash dry particles and primary burnt dry particles on the surface of the adobe, and absorbing the excess mixture with a suction device;

[0084] In this step, the chemical composition of crystal flash dry particles is calculated by weight percentage, including: ZrO 2 : 5%, SiO 2 : 70%, Al 2 o 3 : 1%, B 2 o 3 : 11%, Na 2 O: 10%, Li 2 O: 3%; the chemical composition of the once-burned dry grain is calculated by weight percentage, including: SiO 2 : 58%, Al 2 o 3 : 8%, CaO: 14%, ZnO: 11%, K 2 O: 7%, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com