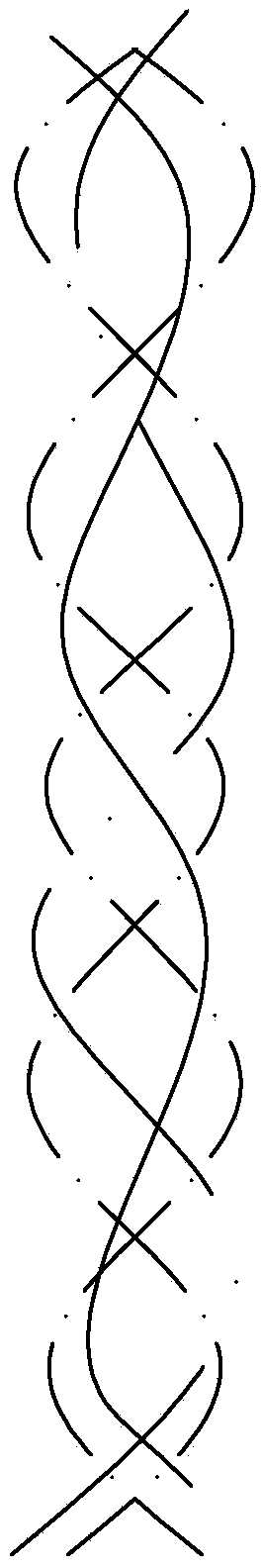

Production method of vortex spun colored silk yarns

A vortex spinning and vortex technology, which is applied in the direction of yarn, textiles and paper making, can solve the problem of not being too high, such as the proportion of pure cotton generally not exceeding 40%, otherwise, it will limit product development, fiber types and air-conditioning environment requirements. Harsh and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of vortex spinning colored cotton yarn of the present invention, concrete steps are as follows:

[0020] (1) Material selection: Colored viscose fiber and flat polyester in red, yellow and blue colors are selected. The proportion of colored viscose fiber added is 70%, and the proportion of added flat polyester of each color is the same, 10%.

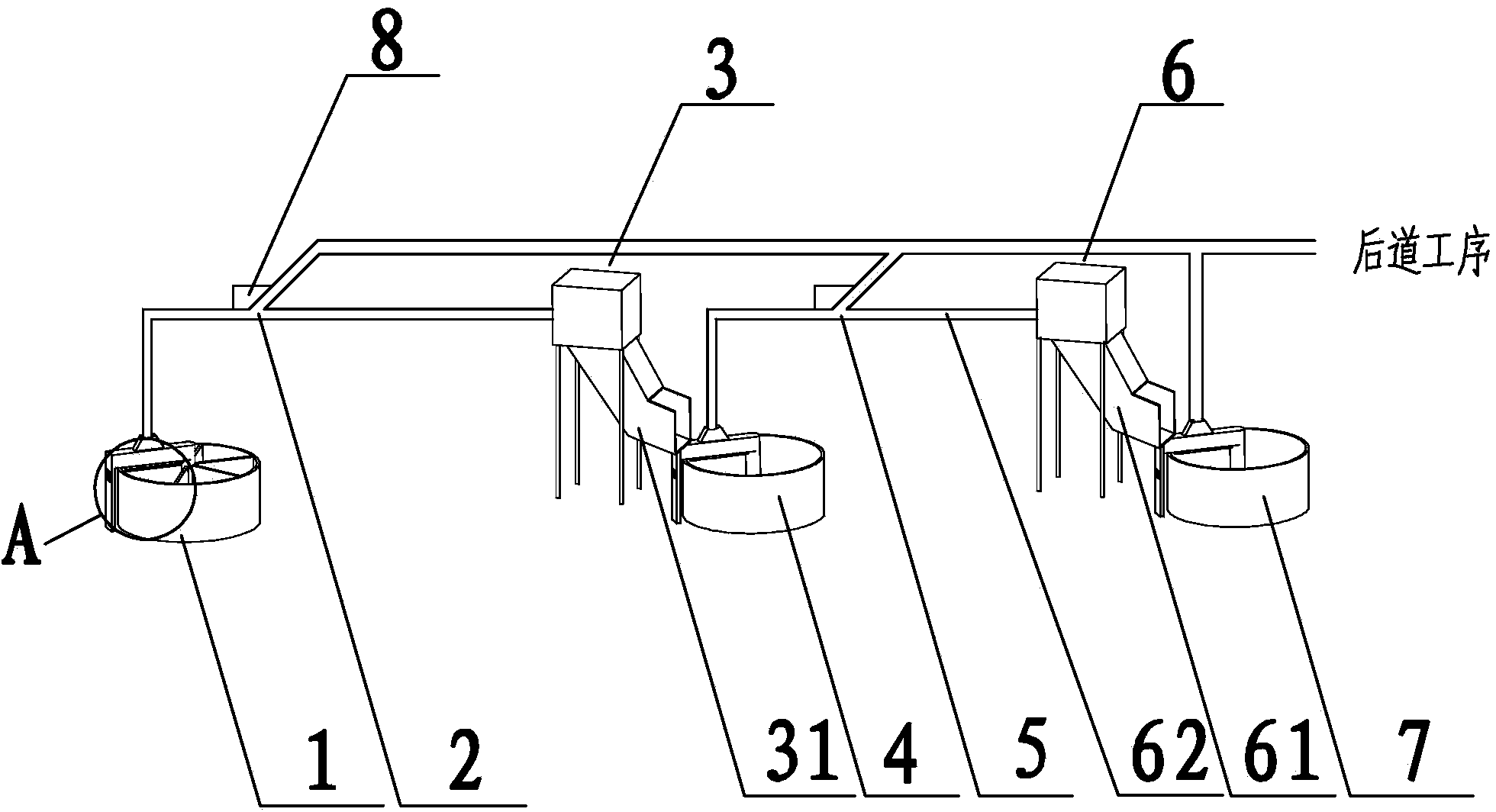

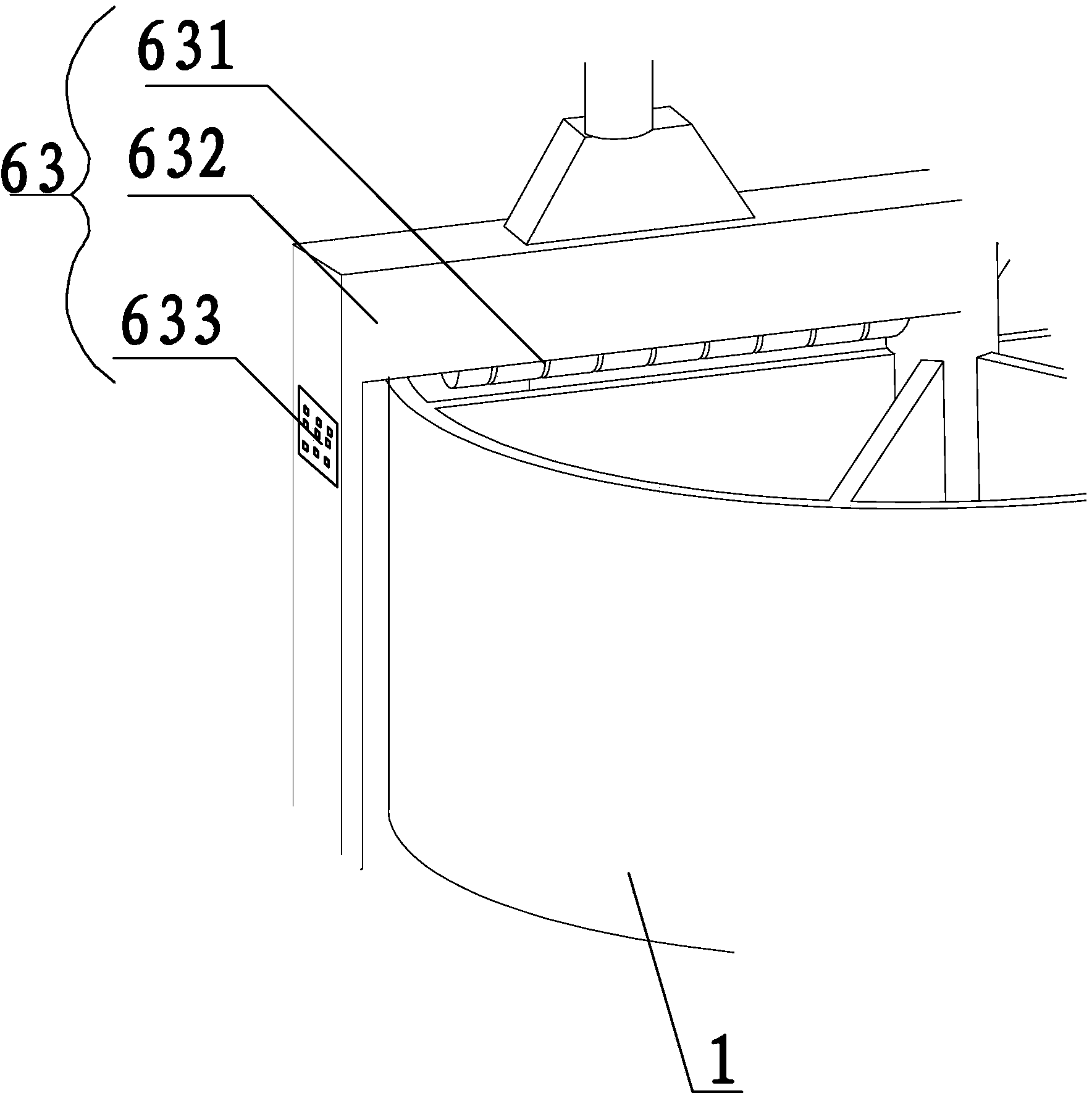

[0021] (2) Premixed strips: Mix the raw materials in step (1) into four mixed strips, two viscose fiber strips and one polyester strip to form a colored premixed strip. The specific mixing method is: first mix flat polyester with colored The viscose fiber is pre-mixed, that is, the colored viscose fiber and flat polyester are placed in the grid of the disc of the cotton mixing device (that is, the disc grabbing machine, FA002), and then sent to the carding machine after opening , enter the drawing frame through the carding machine for pre-drawing to form a mixed sliver, and then form the colored viscose fibe...

Embodiment 2

[0026] The preparation method of vortex spinning colored cotton yarn of the present invention, concrete steps are as follows:

[0027] (1) Material selection: Colored viscose fiber and flat polyester in red, yellow and blue colors are selected. The proportion of colored viscose fiber added is 94%, and the proportion of added flat polyester of each color is the same, 2%.

[0028] (2) Premixed strips: Mix the raw materials in step (1) into three mixed strips, two viscose fiber strips and two polyester strips to form a colored premixed strip. The specific mixing method is: first mix flat polyester with colored viscose The glue fiber is pre-mixed to form a mixed strip, and then the colored viscose fiber and flat polyester fiber are respectively formed into a viscose fiber strip and a polyester strip. Among them, in the pre-mixing, the mixing ratio of flat polyester and colored viscose fiber is 1:0.6, and the colored viscose fiber and flat polyester can be added to 85% of the total...

Embodiment 3

[0033] The preparation method of vortex spinning colored cotton yarn of the present invention, concrete steps are as follows:

[0034] (1) Material selection: Colored viscose fiber and flat polyester in red, yellow, and blue colors are selected. The proportion of colored viscose fiber added is 82%, and the proportion of added flat polyester of each color is the same, all 6%.

[0035] (2) Premixed strips: Mix the raw materials in step (1) into three mixed strips, two viscose fiber strips and two polyester strips to form a colored premixed strip. The specific mixing method is: first mix flat polyester with colored viscose The glue fiber is pre-mixed to form a mixed strip, and then the colored viscose fiber and flat polyester fiber are respectively formed into a viscose fiber strip and a polyester strip. Among them, in the pre-mixing, the mixing ratio of flat polyester and colored viscose fiber is 1:2, and the colored viscose fiber and flat polyester can be added to 80% of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com