Lower traction mechanism capable of being freely opened and closed

A pulling mechanism and free technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of poor stability, inability to realize free opening and closing, and the stability of the lower pulling mechanism affects the qualified rate of fabrics, etc., to increase Work efficiency and the effect of improving the stability of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

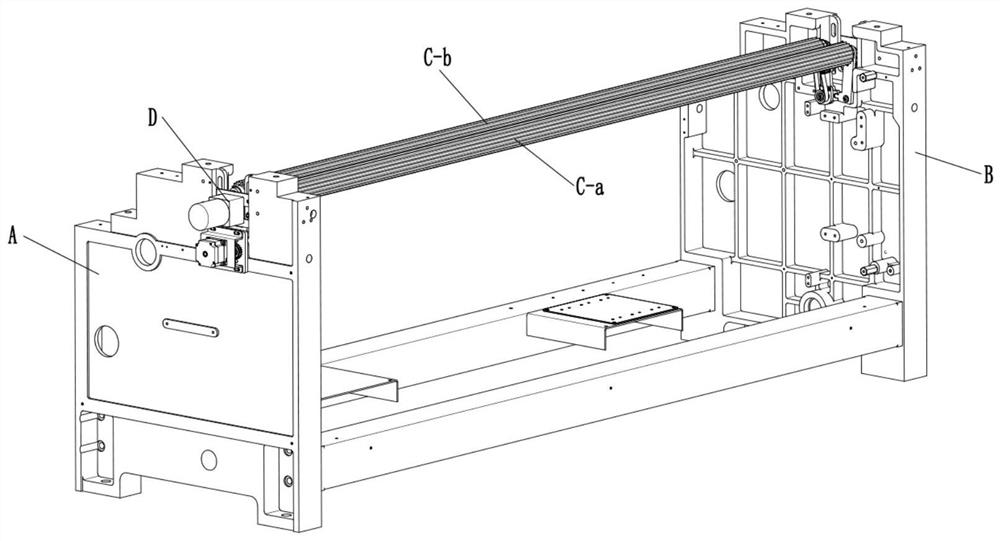

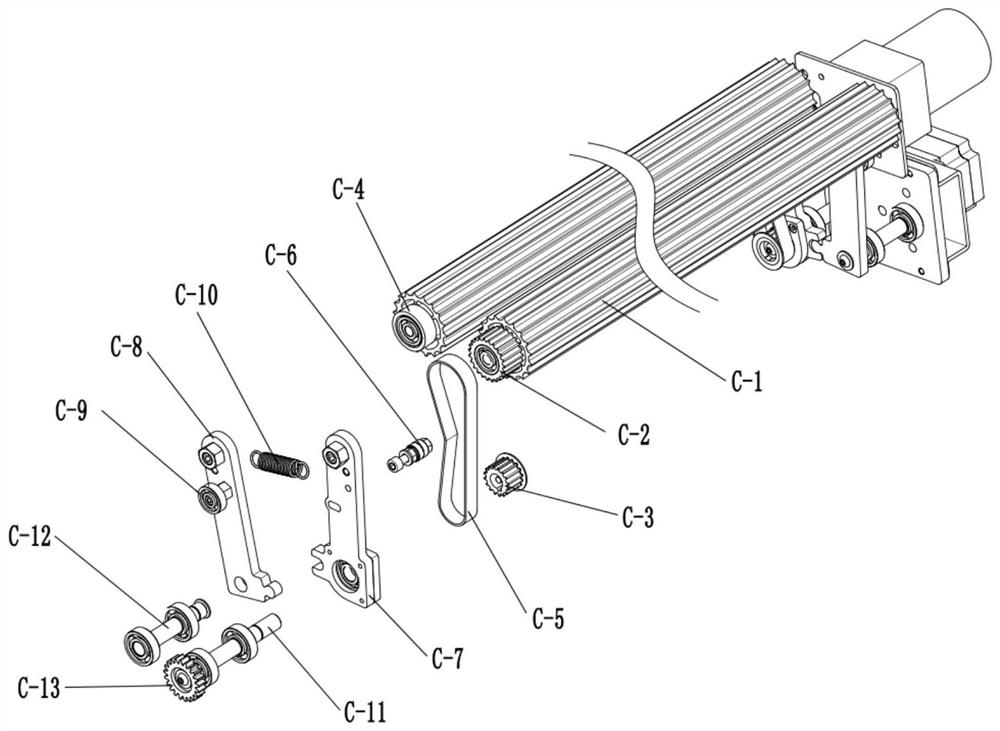

[0023] The invention provides a lower pulling mechanism for realizing free opening and closing, such as figure 1 , 2 As shown, it includes the first pulling roller C-1a and the second pulling roller C-1b installed on the wall board in reverse through the support plate C-15. The two ends of the first pulling roller are respectively connected to the active opening and closing rod C-8 and the driven opening and closing rod C-7, and the two ends of the second pulling roller are respectively connected to the driven opening and closing rod and the active opening and closing rod. The motor D-1 respectively drives the opening and closing movement between the active opening and closing rod and the driven opening and closing rod at both ends, thereby driving the opening and closing movement of the first and second pulling rollers.

[0024] In the present invention, opening and closing motors are installed on the first and second pulling rollers, which can be opened and closed at the sa...

Embodiment 2

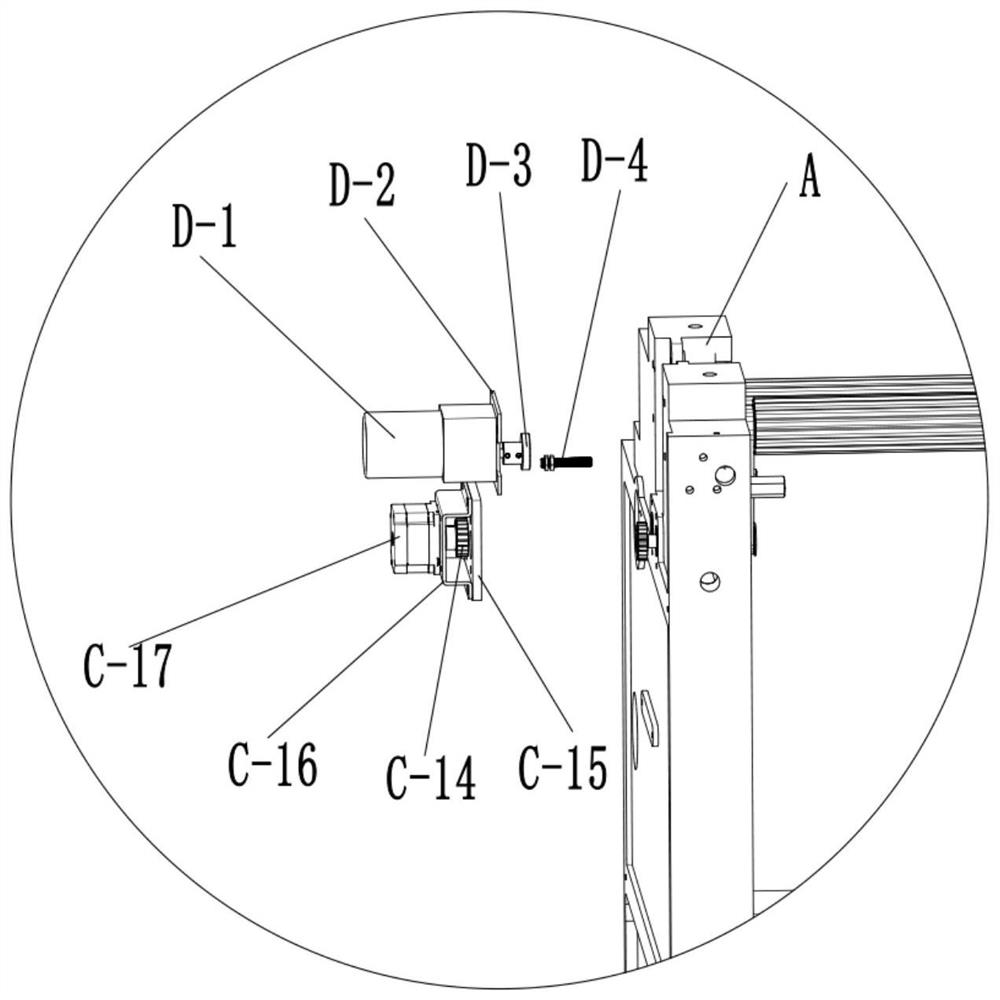

[0026] Such as Figure 4 , 5 As shown, the active opening and closing rod C-8 is connected to the wallboard through the auxiliary shaft C-12, and the active opening and closing rod and the auxiliary shaft are fixed in the circumferential direction; the driven opening and closing rod C-7 is connected to the wall board through the rotating shaft C-11. On the board, the driven opening and closing rod and the active opening and closing rod are connected to each other, and the connection method can be shown in the figure. There is a bearing between the transmission shaft and the driven opening and closing rod, and the bottom ends are engaged with each other. Driven by the opening and closing cam D-3, the active opening and closing lever can swing at a certain angle, and drives the driven opening and closing lever to open or close each other, and the top ends of the driven opening and closing lever and the active opening and closing lever are connected by a tension spring.

[0027]...

Embodiment 3

[0031] Such as Figure 1-3 As shown, the pulling mechanism of the present invention is respectively provided with stepper motor C-17 on the first and second pulling rollers, and the stepping motor drives the gear on the pulling roller to rotate by driving the pulley mechanism. 1. The rotation of the second pulling roller completes pulling the fabric. The pulley mechanism includes a transmission shaft, a driving gear and a driven gear.

[0032] The output shaft end of the stepper motor is provided with a driving gear C-14, and a driven gear C-13 is provided on the outside of the transmission shaft, and the driving gear and the driven gear are meshed with each other; a driven opening and closing rod and a driving pulley are provided on the inside of the transmission shaft The driving pulley C-3 and the transmission shaft are fixed in the circumferential direction, the end of the pulling roller is provided with a driven pulley C-2, the driving pulley and the driven pulley are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com