A film coating device for a packaging machine

A film device and packaging machine technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve problems such as tearing, increased material costs, and packaging film not fully tensioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

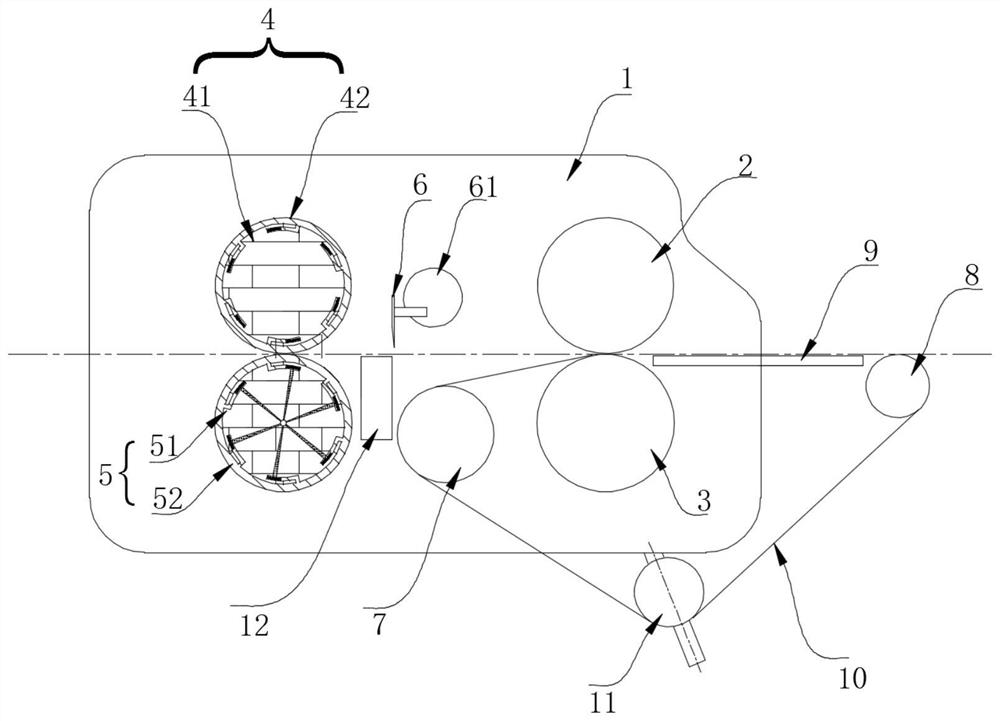

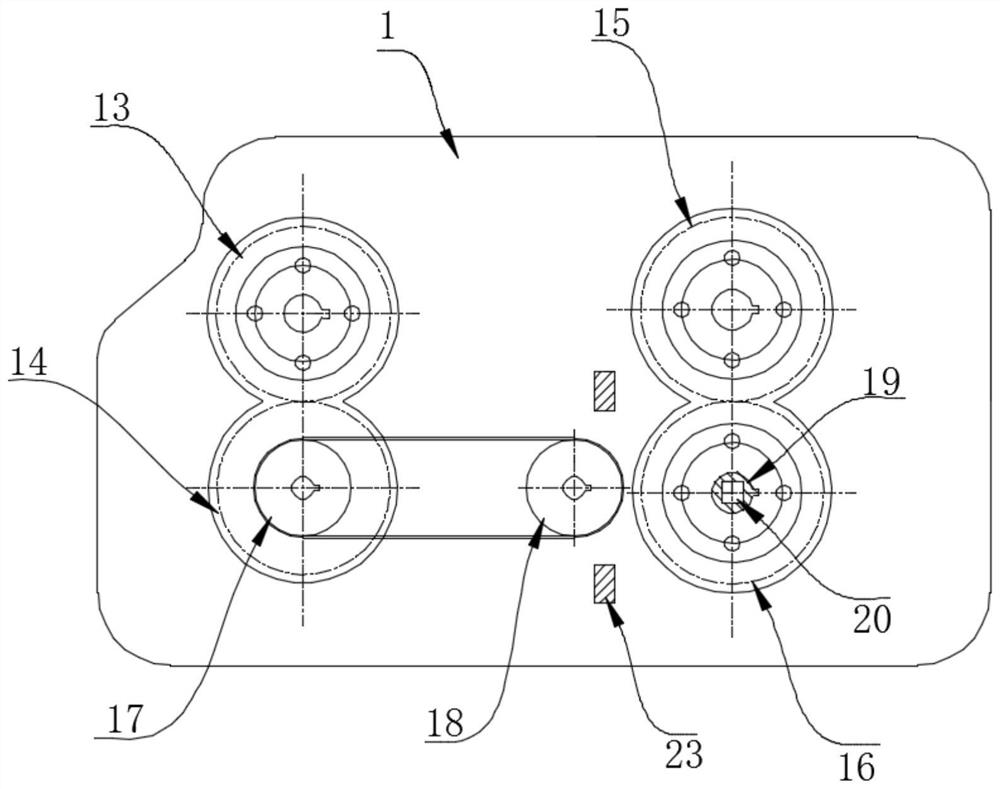

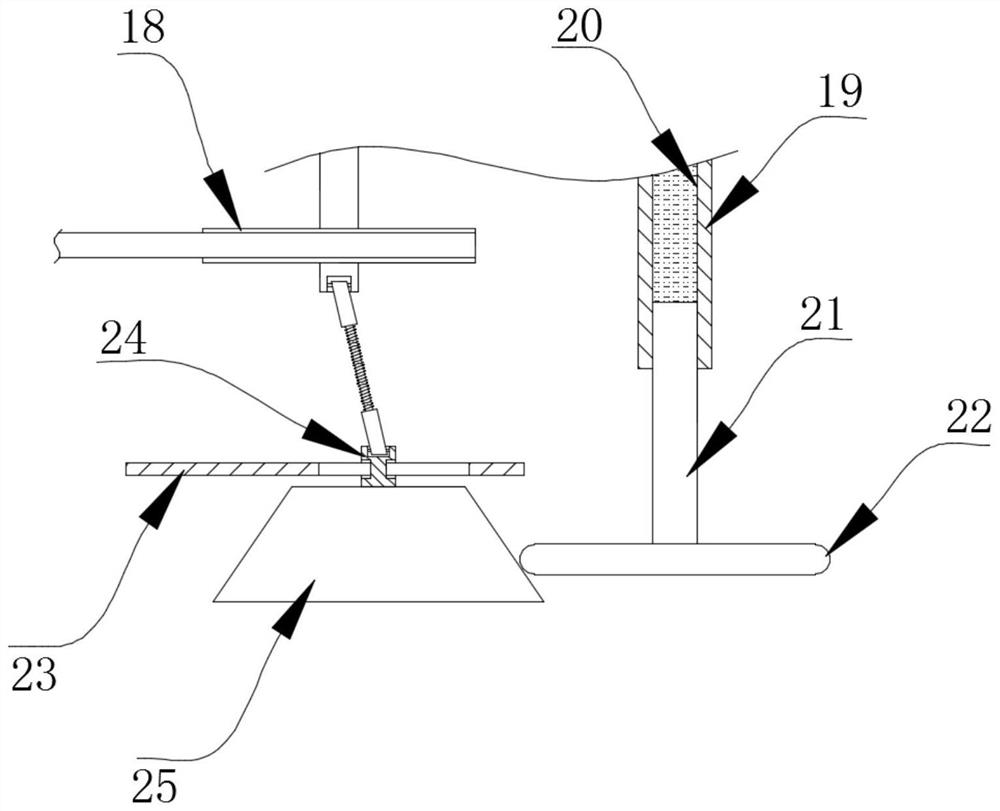

[0028] refer to Figure 1-4 , a film coating device for a packaging machine, comprising: a pair of front film feed rollers and a pair of rear film feed rollers arranged on a base plate 1, and a pair of front film feed rollers include front film top pressure rollers that are cooperating up and down. 2 and the front film feeding lower pressure roller 3, a pair of rear film feeding pressure rollers include the rear film feeding upper pressure roller 4 and the rear film feeding lower pressure roller 5, which are arranged up and down, between the front and rear two pairs of film feeding pressure rollers A cutter shaft 61 equipped with a cutter 6 is provided, the cutter 6 is positioned above the packaging film, a backing plate 12 for cutting with the cutter 6 is provided below the packaging film, and a front auxiliary feeder is provided below the cutter 6. The film roller 7 is provided with a rear auxiliary film delivery roller 8 on the outside of the front film lower pressure rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com