Hot press molding process of paper tray

A technology of thermoforming and pressure forming, which is applied in the direction of textiles and papermaking, etc., can solve the problems of high cost, white pollution, non-conforming to environmental protection, etc., and achieve the effects of low production cost, product protection, and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

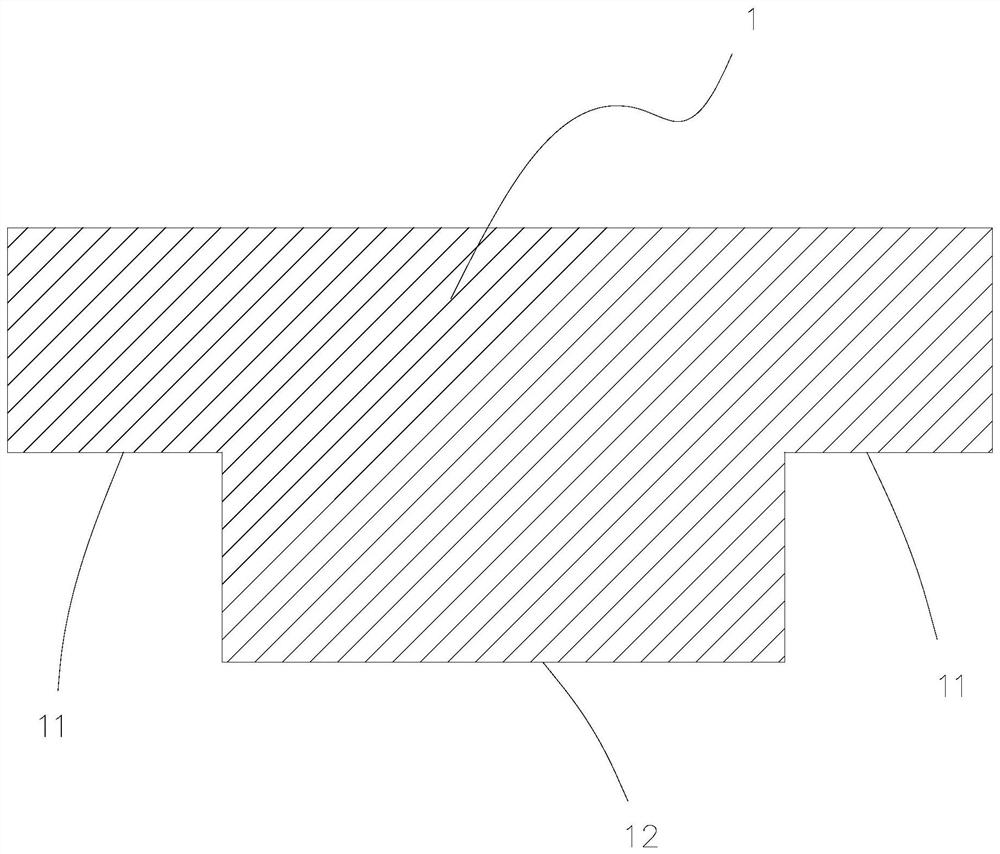

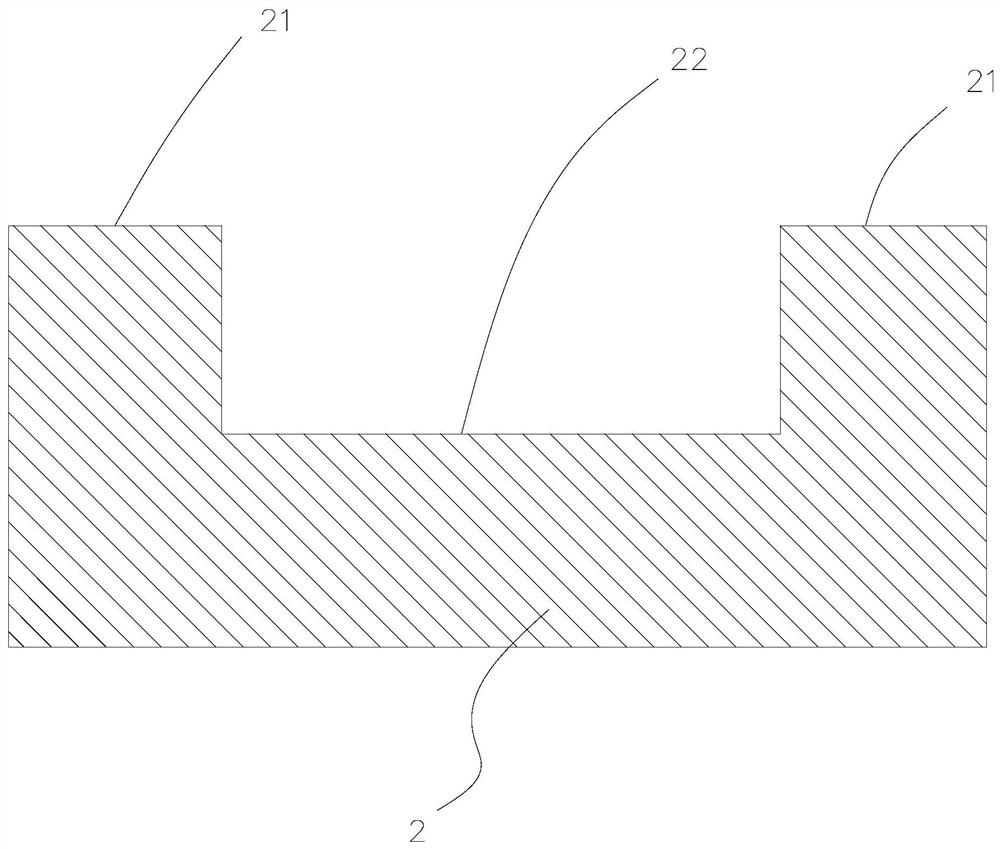

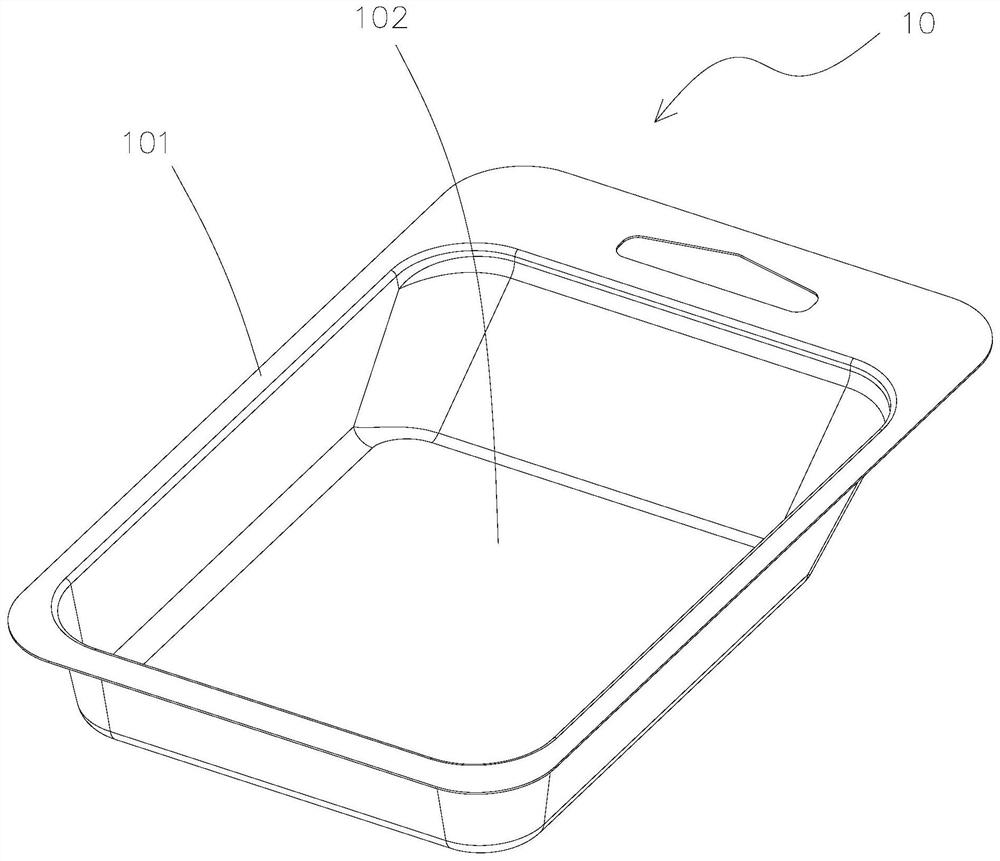

[0023] A heat press molding process for a paper tray, comprising the following steps: feeding, placing flat paper between an upper mold 1 and a lower mold 2; heating, heating the upper mold 1 or lower mold 2 to raise the temperature to Temperature T; pressure molding, press the upper mold 1 to the lower mold 2, and control the pressure to maintain the pressure P within the time t; demould, separate the upper mold 1 and the lower mold 2, so as to obtain the formed paper Tray 10.

[0024] Preferably, long-fiber paper with an interlayer bonding force of not less than 300gsm is used for the plane paper, and white cardboard is especially suitable.

[0025] Preferably, the temperature T is between 150°C and 180°C.

[0026] Preferably, the time t is between 1.5 seconds and 3 seconds.

[0027] Preferably, the pressure P is between 5Mpa and 10Mpa.

[0028] The above-mentioned thermocompression forming process of a paper tray also includes the following steps: printing, printing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com