Heater for heating medium to form gas dispersion system

A technology of gas dispersion and heating medium, which is applied to tobacco and other directions, can solve problems such as high cost and complicated process, and achieve the effects of improving heating efficiency, simple processing technology and obvious heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

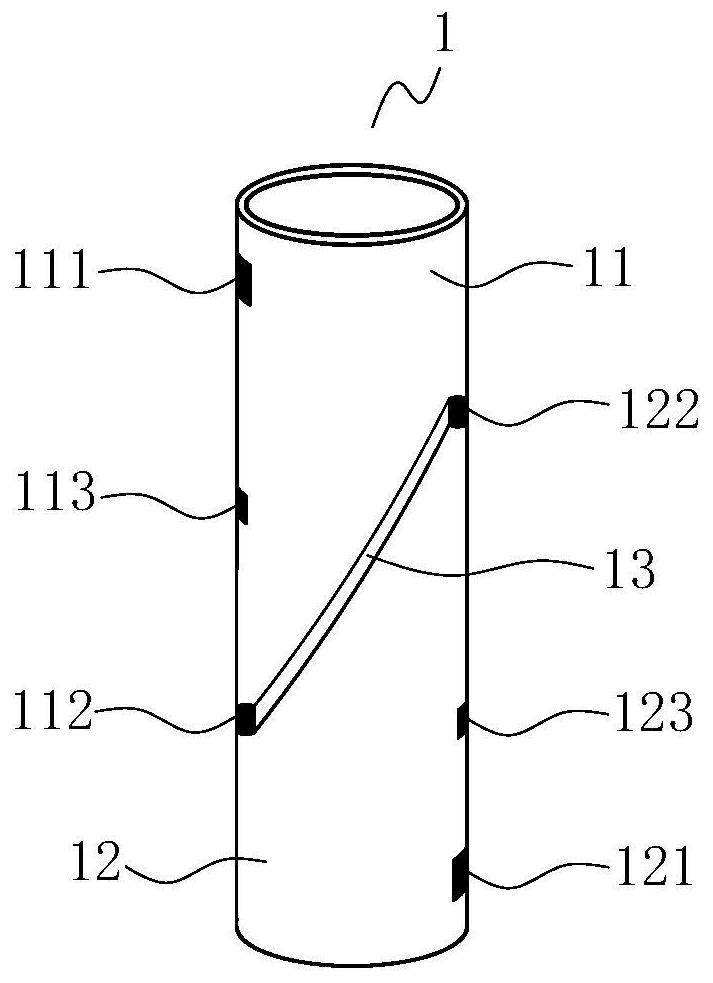

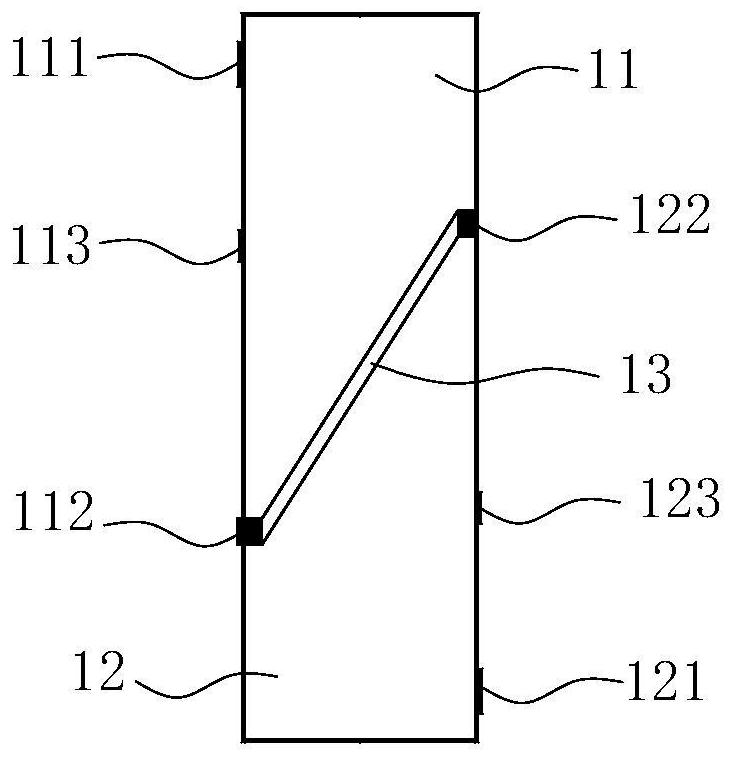

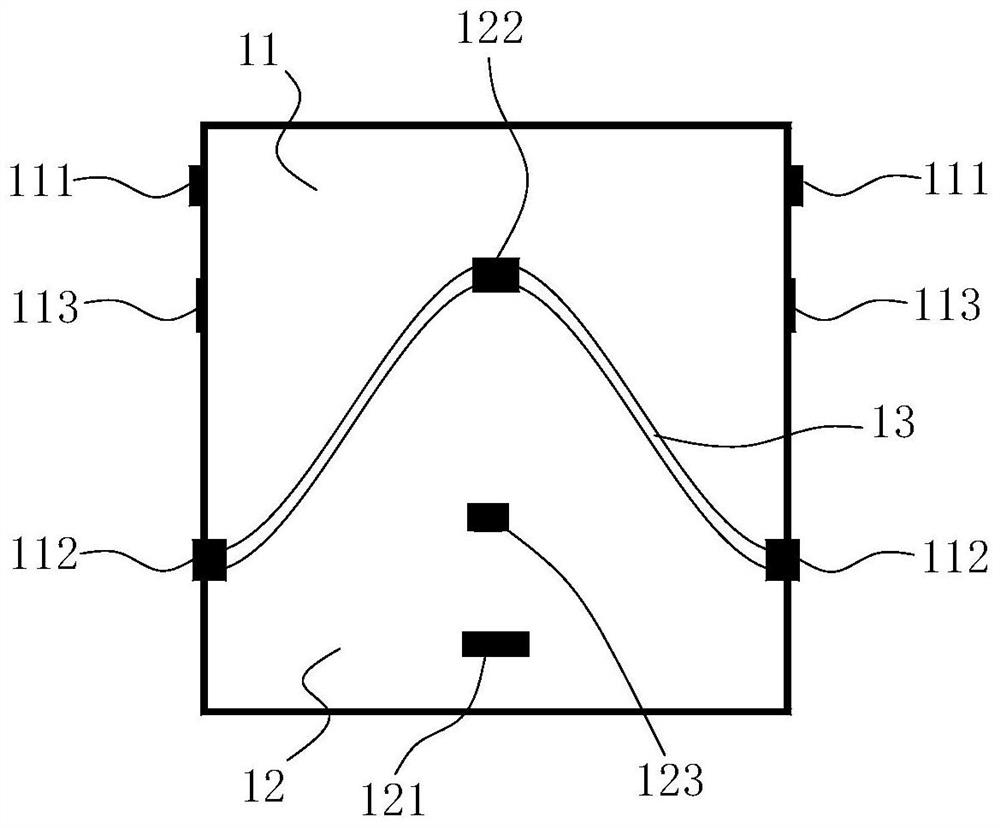

[0031] see figure 1 , the heating tube 1 in the illustration is an embodiment of the present invention. The heating tube 1 is a tube body structure with two ends open, one end of which is used to insert a smoking medium into the inner cavity of the tube, including but not limited to cigarettes or The cartridge, the tube body of the heating tube 1 itself can be made into a resistance for baking and heating the inserted smoking medium. The heating tube is a semiconductor, and polycrystalline materials are evenly mixed inside it. The tube body of the heating tube 1 is in the state of being energized It can heat up and generate heat, so as to heat the inserted smoking medium and release it to form a gas dispersion system. In this embodiment, the pipe body is divided into a first heating part 11 and a second heating part 12 which can generate heat independently by the temperature control belt 13, and the different areas of the smoking medium are controlled by the first heating part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com