Adjustable ammonium phosphate salt dry powder fire extinguishing device

A technology of dry powder fire extinguishing and ammonium phosphate salt, which is applied in the direction of mechanical fire alarms and fire rescue, and can solve the problems that fire extinguishers cannot be moved and are laborious to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

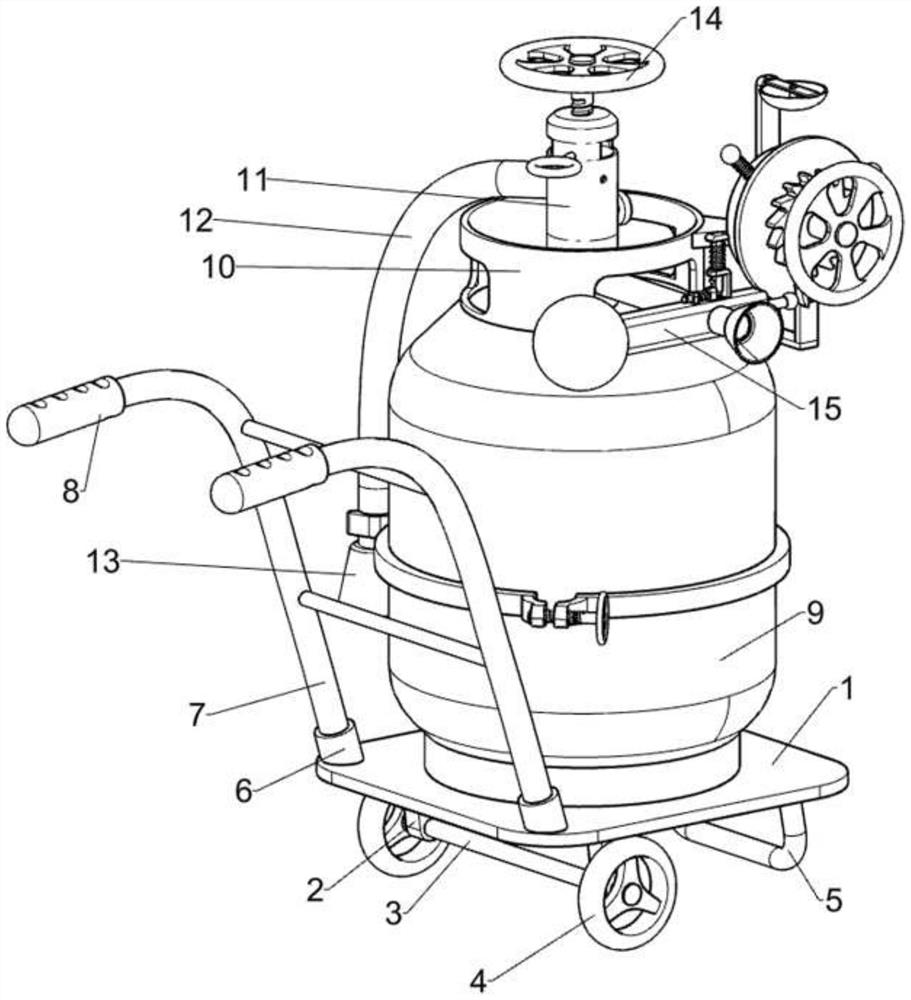

[0030] like figure 1 As shown, an adjustable ammonium phosphate dry powder fire extinguishing device includes a bottom plate 1, a bearing seat 2, a bearing shaft 3, a roller 4, a pressure rod 5, a first connecting block 6, a handle 7, a grip 8, and a storage tank 9. Connecting seat 10, first conduit 11, hose 12, first spout 13, control mechanism 14 and automatic spraying mechanism 15, the left side of the bottom of the bottom plate 1 is symmetrically provided with a bearing seat 2, two of the bearing seats 2 A load-bearing shaft 3 is rotatably provided in between, rollers 4 are provided at the front and rear ends of the load-bearing shaft 3, a pressure bar 5 is provided on the right side of the bottom of the bottom plate 1, and a first connecting rod is arranged symmetrically on the left side of the top of the bottom plate 1. block 6, a handle 7 is provided between the two first connecting blocks 6, handles 8 are provided on the front and rear sides of the left part of the han...

Embodiment 2

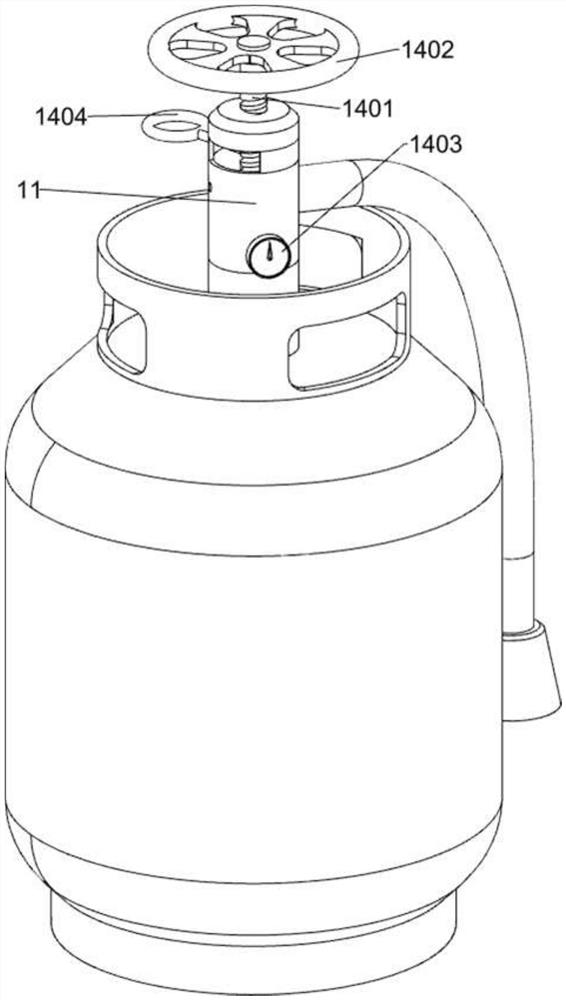

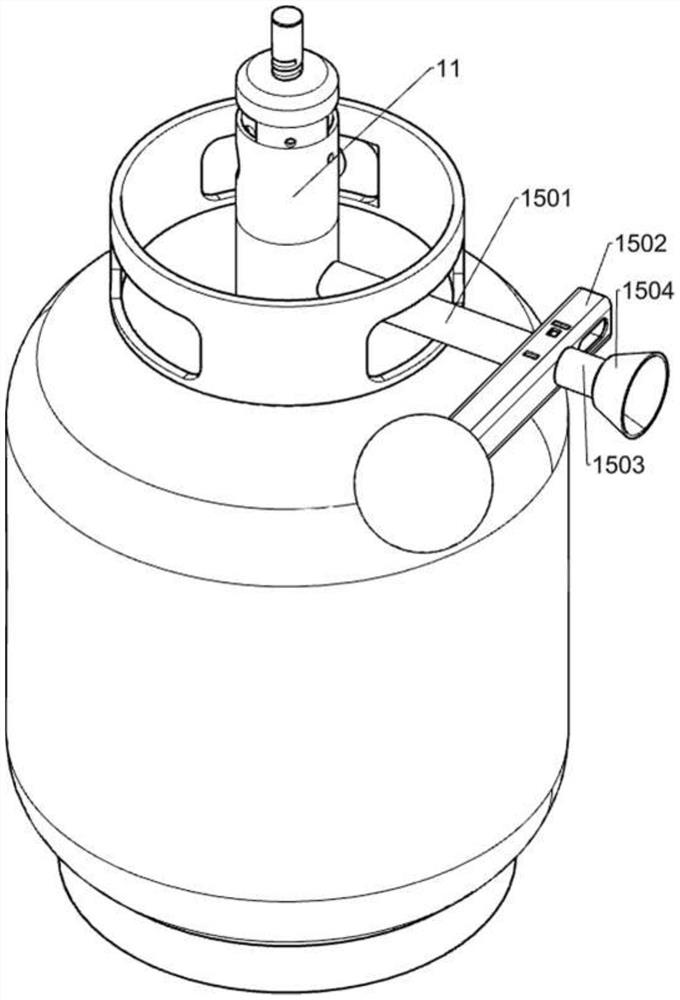

[0033] like figure 2 , image 3 , Figure 4 and Figure 5As shown, on the basis of Embodiment 1, the control mechanism 14 includes a first bolt 1401, a first handwheel 1402, a pressure gauge 1403 and a safety pin 1404, and the top of the first conduit 11 is provided with a first bolt 1401, the top of the first bolt 1401 is provided with a first hand wheel 1402, the right side of the first conduit 11 is provided with a pressure gauge 1403, the first conduit 11 is slidably provided with a safety pin 1404, and the safety pin 1404 and The first bolt 1401 fits.

[0034] After the roller 4 rotates to move the device to the position where the fire needs to be extinguished, the staff pulls out the safety pin 1404, at this time the staff holds the first nozzle 13 to point to the fire point, and then the staff turns the first hand wheel 1402 to drive the first bolt 1401 moves upward, the first bolt 1401 moves upward to open the dry powder fire extinguisher, and the dry powder in th...

Embodiment 3

[0038] like figure 2 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a first guide rod 16, a first spring 17 and a first small steel ball 18. The right side of the slider 1505 is provided with a first guide rod 16, and the first guide rod 16 runs through the right end of the hollow tube 1502. A first spring 17 is disposed between the right side of the slider 1505 and the right end of the hollow tube 1502 , and a first small steel ball 18 is disposed at the right end of the first guide rod 16 .

[0039] The slider 1505 slides to the right in the hollow tube 1502, the first spring 17 is compressed, and the slider 1505 slides to the right to drive the first guide rod 16 to slide to the right in the hollow tube 1502. , the reset of the first spring 17 drives the slide block 1505 to slide to the left in the hollow tube 1502 to reset, and the slide to the left of the slide block 1505 drives the first guide rod 16 to slide to the left in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com