Lifting device

A lifting device and driving device technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of high safety risk factor, high cost of screw jacking mechanism, high center height of equipment and products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As required, specific embodiments of the invention will be disclosed herein. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

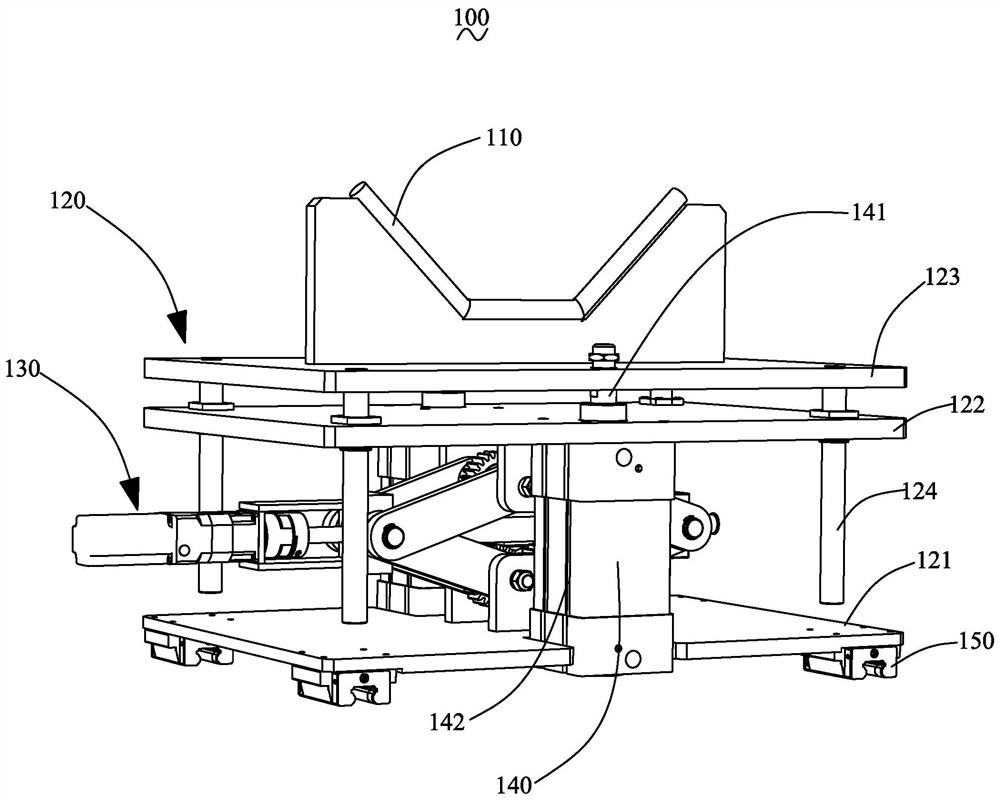

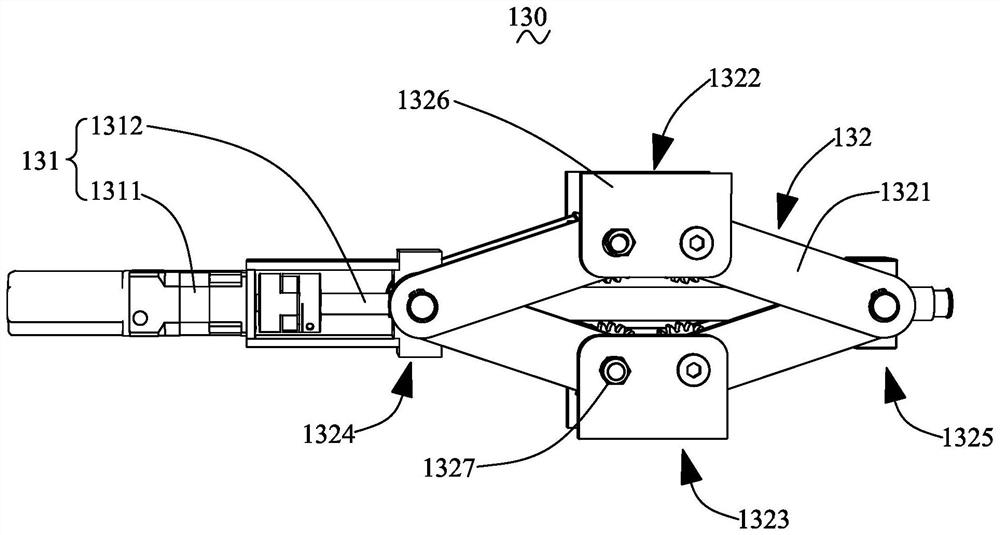

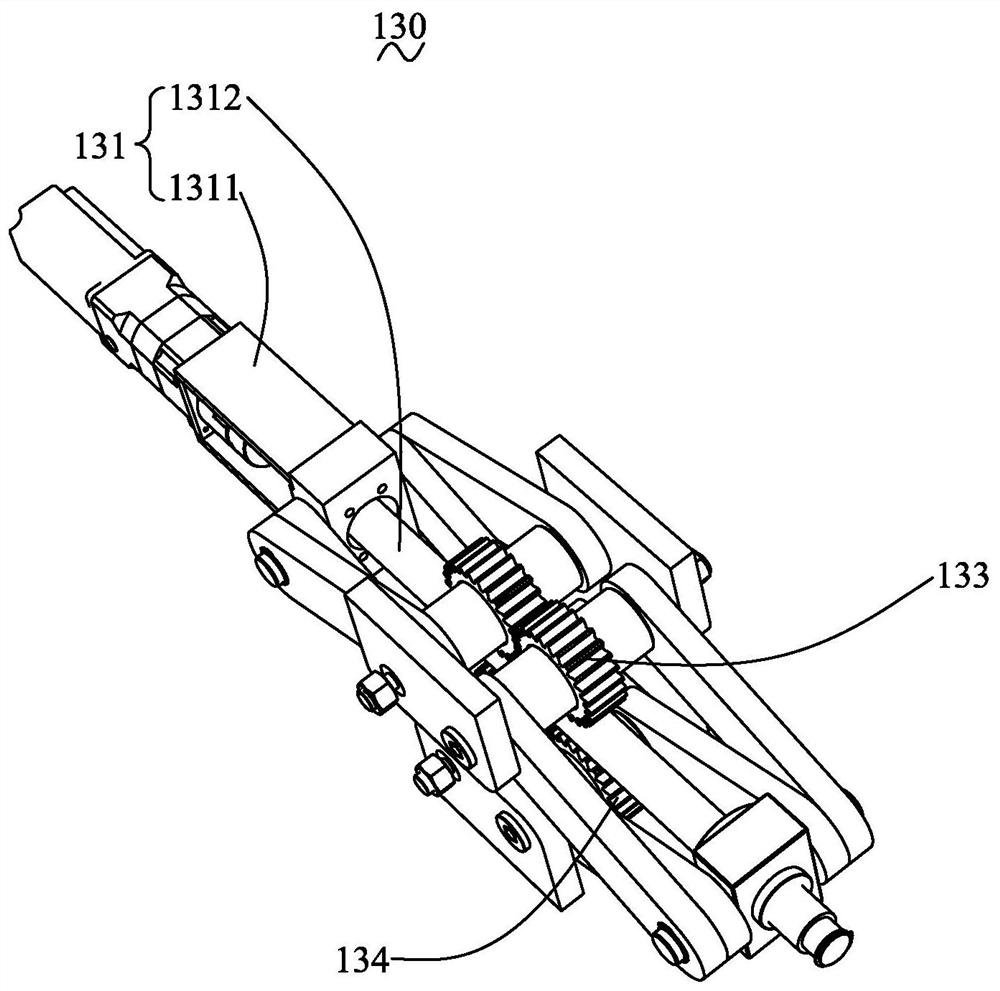

[0020] Such as figure 1 As shown, this embodiment provides a lifting device 100 for supporting and lifting insulators, including a lifting assembly 120 and a supporting assembly 110. The lifting assembly 120 includes a bottom plate 121, two The first-level jacking panel 122 and the first-level jacking panel 123, the guide rod 124 passes through the first-level jacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com