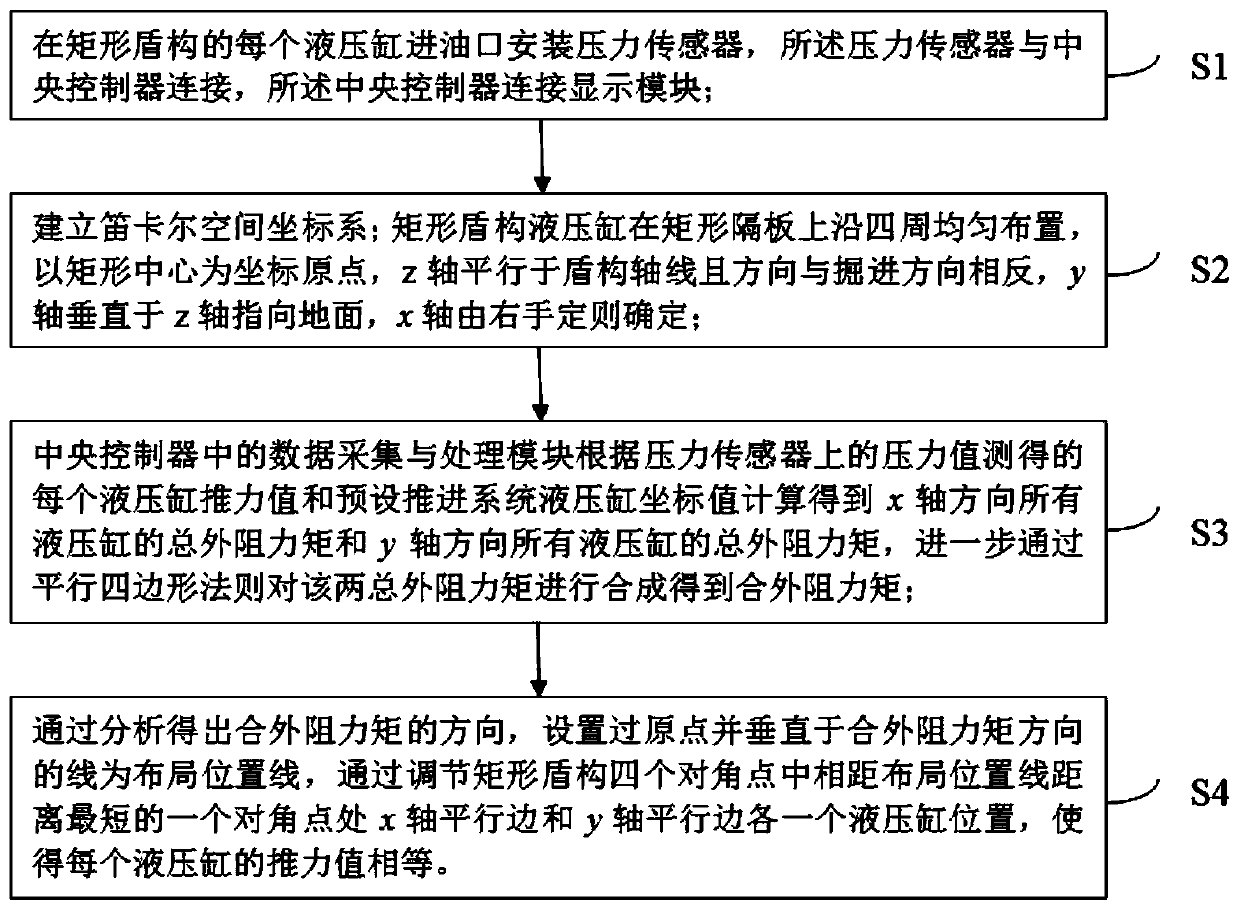

A method for adjusting propulsion hydraulic cylinder to realize anti-eccentric load of rectangular shield

An adjustment method, the technology of rectangular shield, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of affecting the quality of tunnel construction, increasing the difficulty of adjustment, and segment crushing, so as to increase the scope of applicable strata, Reduces deformation of the propulsion system, protects against damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

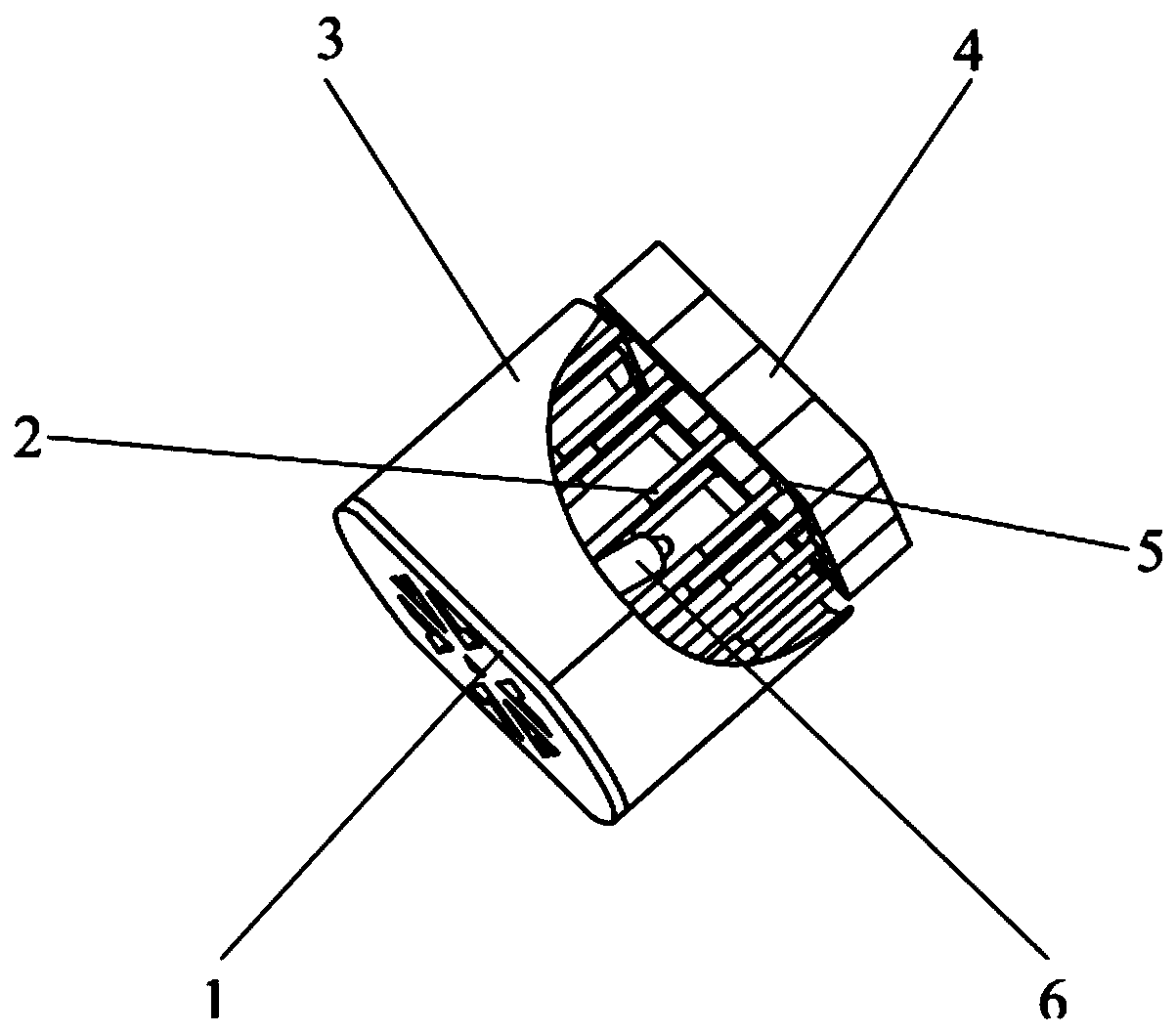

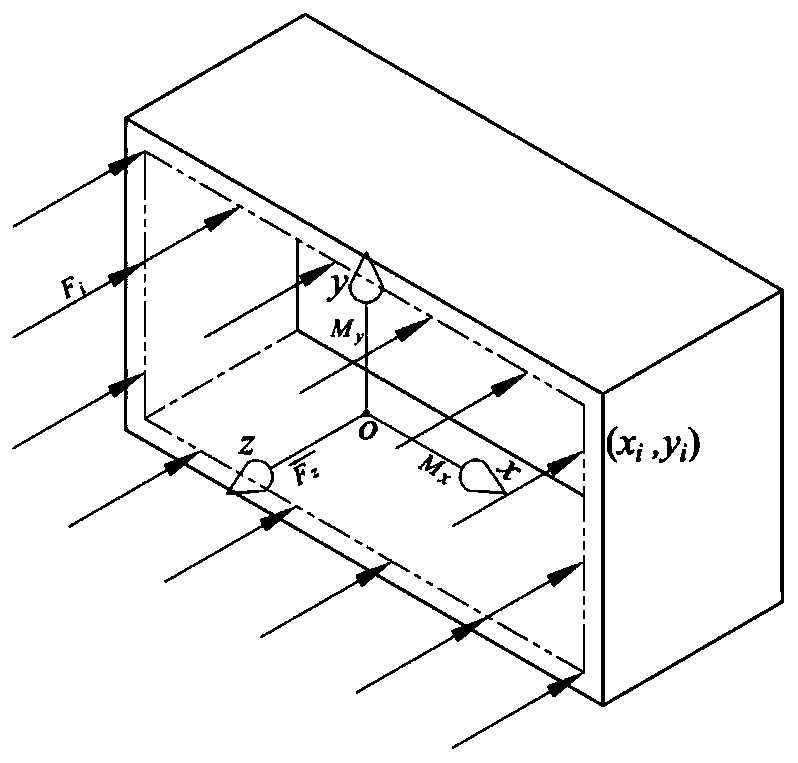

[0038] Such as figure 2 shown and Image 6 As shown, the rectangular shield machine mainly includes a shield head 1, a hydraulic cylinder 2, a shield shell 3, a support shoe 5, and a screw conveyor 6; wherein the cutter head on the shield head 1 cuts rocks and soil through the screw conveyor 6 and conveys them out. The left end of the hydraulic cylinder 2 is connected to the shield head 1, the right end is hinged with the support shoe 5, and finally pushes against the segment 4, and the reaction force of the segment 4 is used to push the shield forward; the oil inlet of each hydraulic cylinder 2 is connected to There is a pressure sensor, and the pressure sensor is connected with a central controller, and a data acquisition and processing module is arranged in the central controller, and the central controller is connected with a display module.

[0039] Such as Figure 4 As shown, when combined external resistance torque M 合 with rectangular y The axis-parallel sides in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com