Railway steel rail breaking emergency treatment method convenient for one-man operation

A single-person operation and emergency treatment technology, applied in the direction of rail joints, roads, tracks, etc., can solve the problems of inability to deal with the broken rail in time, increase the time of train interruption, threaten the safety of train operation, etc., to reduce economic losses and Negative social impact, shortening the time of train interruption, and improving the efficiency of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

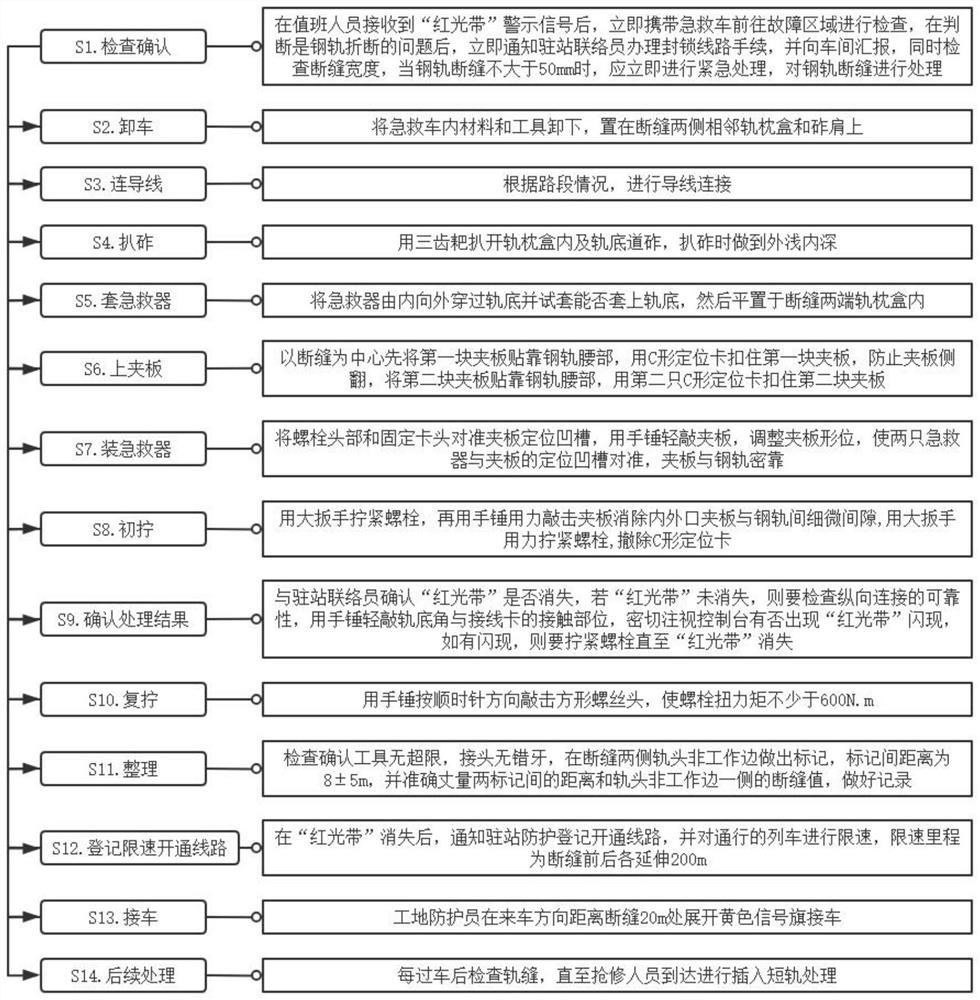

[0067] see Figure 1-10 , an emergency treatment method for railway rail breakage that is easy to be operated by a single person, comprising a rail 1 and a sleeper box 2, comprising the following steps:

[0068] S1. Inspection confirmation: After receiving the "red light belt" warning signal, the on-duty personnel immediately take the ambulance 3 to the fault area for inspection, and after judging that the rail 1 is broken, immediately notify the liaison officer at the station to handle the blockade procedures , and report to the workshop, and check the width of the broken seam at the same time. When the broken seam of rail 1 is not greater than 5Omm, emergency treatment should be carried out immediately to deal with the broken seam of rail 1;

[0069] S2. Unloading: unload the materials and tools in the ambulance 3, and place them on the adjacent sleeper boxes 2 and ballast shoulders on both sides of the broken seam;

[0070] S3. Wire connection: connect the wires according ...

Embodiment 2

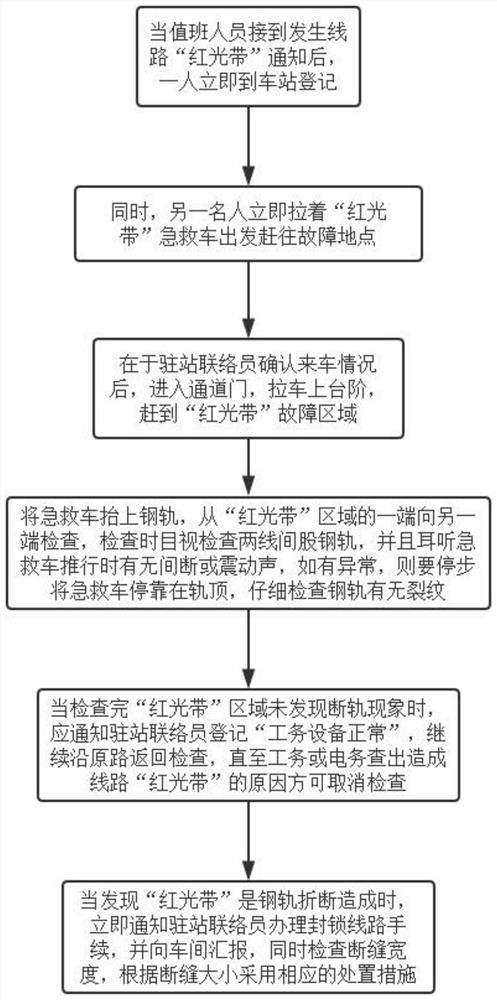

[0087] see figure 1 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , the method for checking whether the rail 1 is broken in step S1 is:

[0088] P1. When the on-duty staff receives the notice of the "red light belt" on the line, one person immediately registers at the station;

[0089] P2. At the same time, another person immediately pulled the "red light belt" ambulance 3 and set off to the fault location;

[0090] P3. After the on-station liaison officer confirms the arrival of the vehicle, enter the passage door, pull the vehicle up the steps, and rush to the "red light belt" fault area;

[0091] P4. Lift the ambulance 3 onto the rail 1, and check from one end of the "red light belt" area to the other end. ...

Embodiment 3

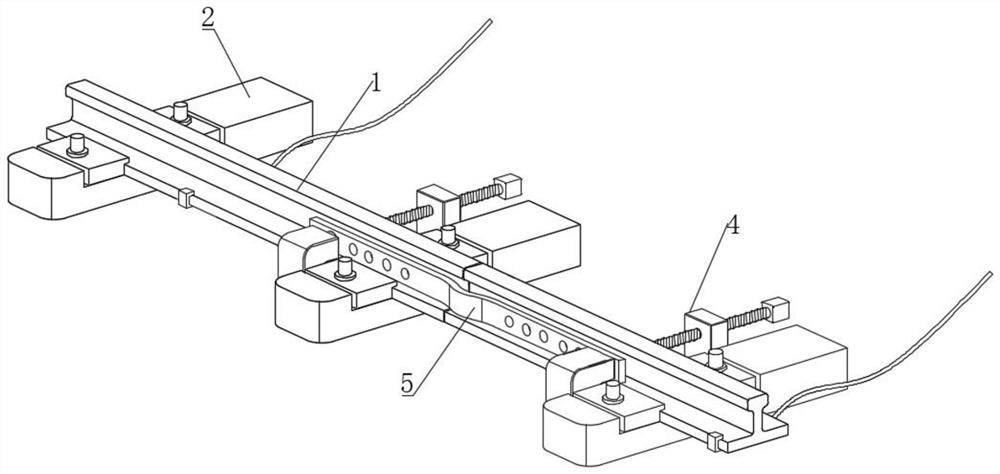

[0095] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 5 , the ambulance 3 includes a vehicle frame 301, the bottom of the vehicle frame 301 is fixedly connected with a first aid box 302, both sides of the vehicle frame 301 are equipped with triangular road wheels 303, the triangular road wheels 303 are equipped with locking devices 305, and the bottom of the vehicle frame 301 is equipped with The rail travel wheel 304 that matches with 1. By using the ambulance 3, the personnel on duty can quickly carry tools for emergency treatment, improve the response efficiency of the personnel on duty, and shorten the time for troubleshooting. Physical exertion, and the ambulance 3 can effectively walk on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com