Viaduct concrete curing device

A technology for concrete and viaduct is applied in the field of curing equipment for preparing concrete, which can solve problems such as inconvenience of water spray curing, and achieve the effects of overcoming construction site limitations, improving maintenance progress and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

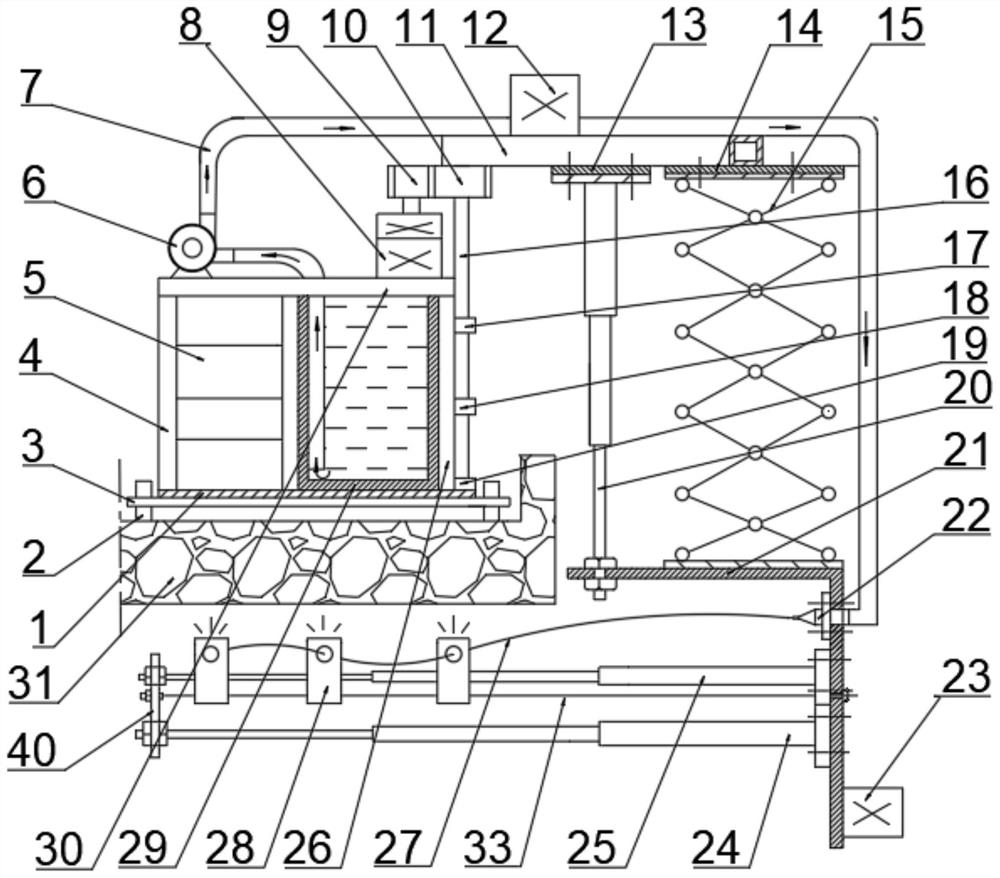

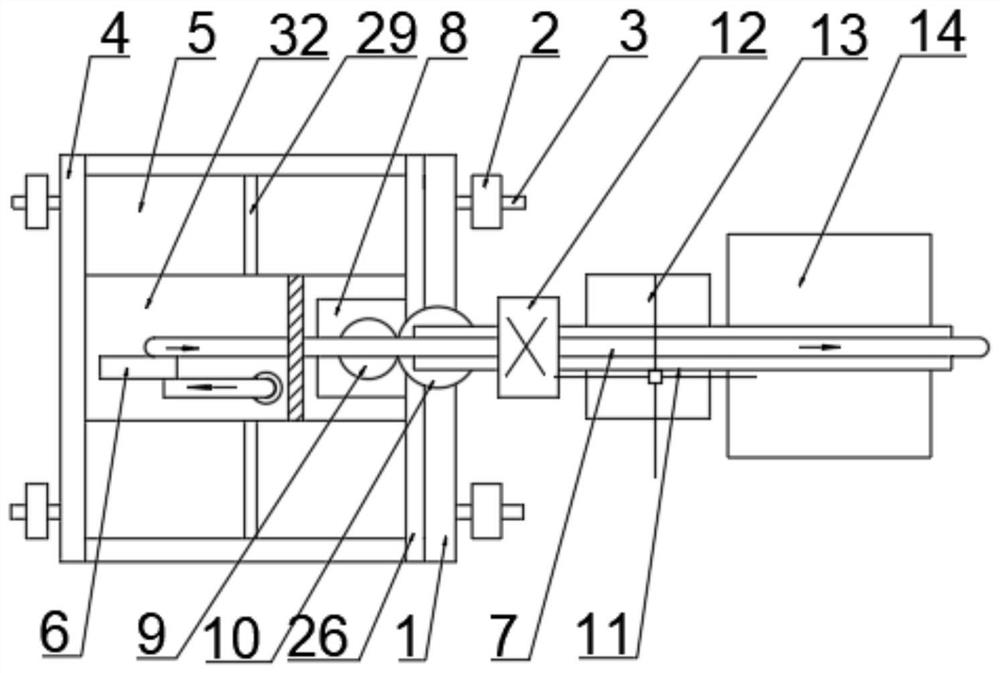

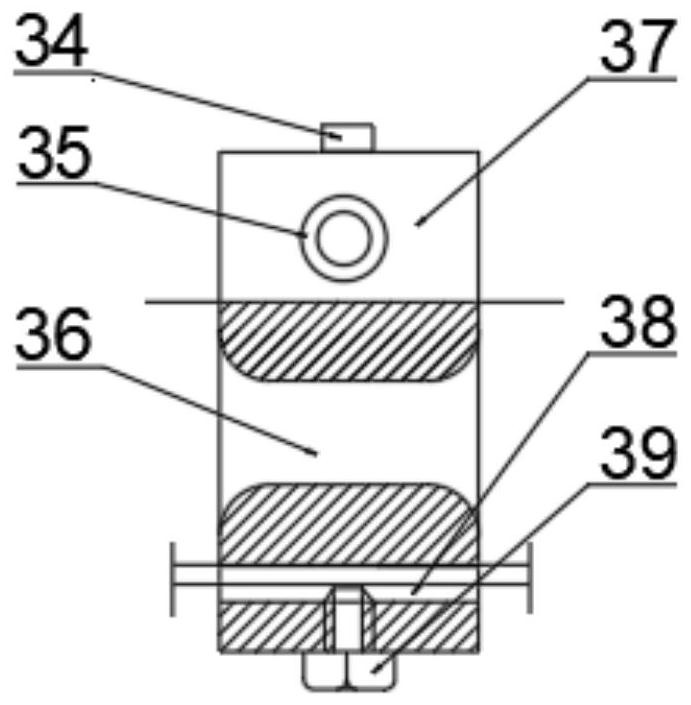

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The viaduct concrete maintenance device provided by the invention is provided with a frame part, a rotating reset part, an up and down telescopic part, a left and right telescopic part and a water spray part.

[0023] The frame part of the present invention comprises a frame bottom plate 1, a left side frame 4, an upper side frame 30, a right side frame 26, a water pump and a reset motor support plate 32, a counterweight 5 and a water tank 29, a frame bottom plate, a left side frame The side frame, the upper side frame, the right side frame, the water pump and the reset motor support plate are welded and connected to form a frame box, and the counterweight 5 is placed on the leftmost side of the frame to adjust the entire equipment center of gravity, balance the overall equipment, counterweight 5 is set to a plurality of blocks, easy to adjust, pick and place, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com