Civil engineering foundation pit building and reinforcing method

A technology for civil engineering and foundation pits, applied in infrastructure engineering, construction, excavation, etc., can solve the problems of long time, high labor intensity, inconvenient disassembly and modification, etc., to achieve easy disassembly and assembly, high labor intensity, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

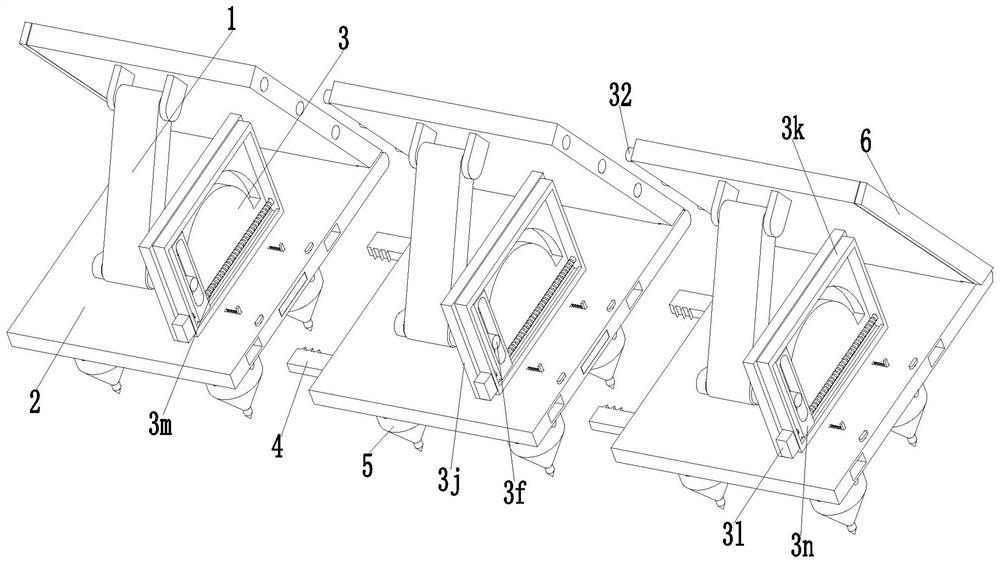

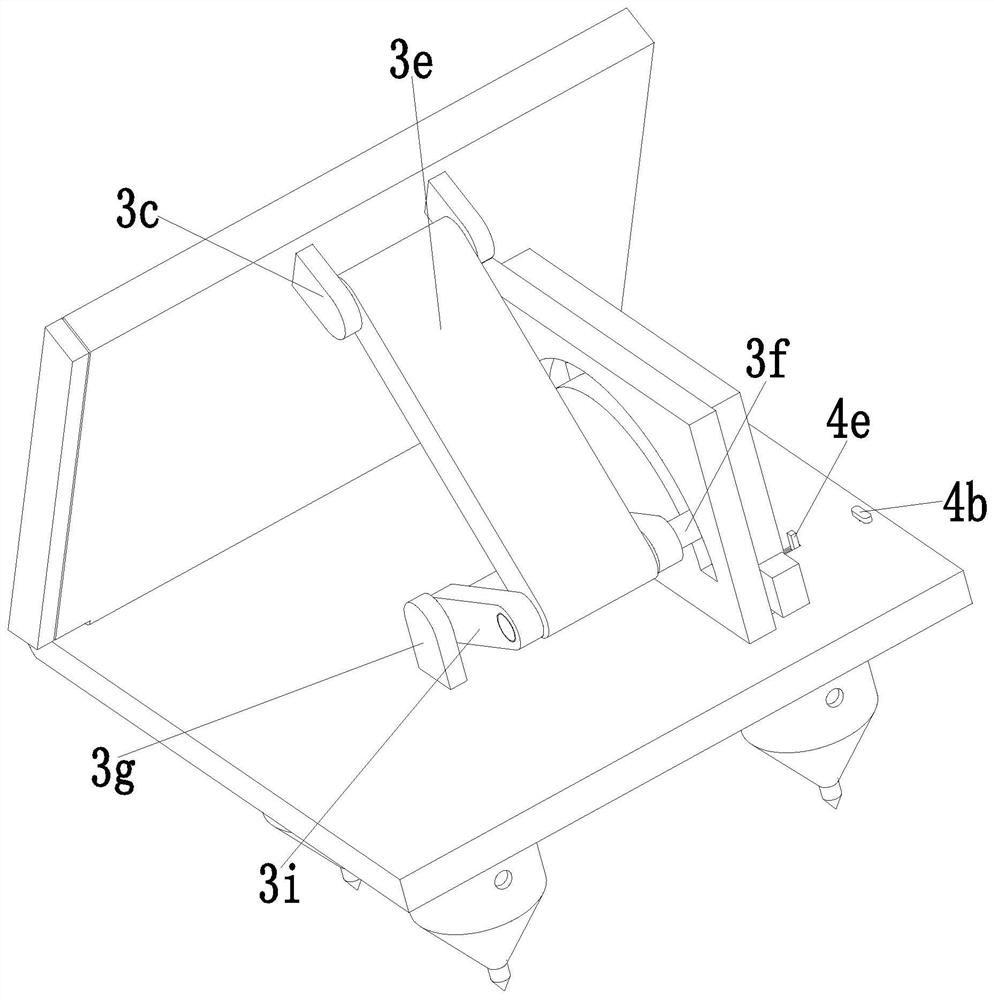

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

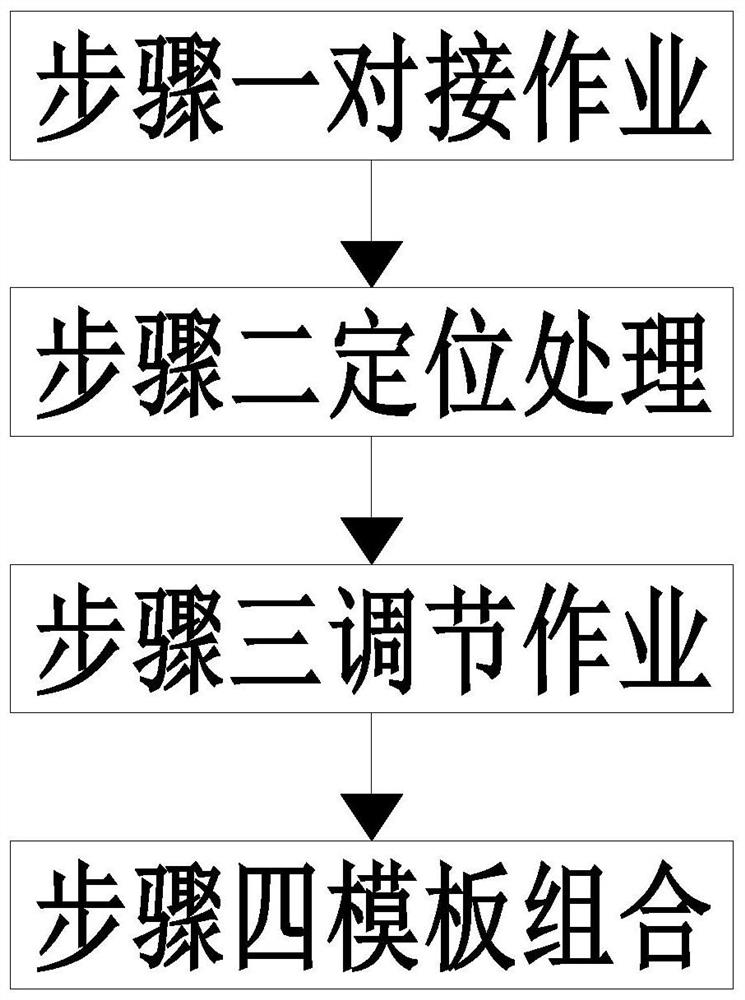

[0033] Such as Figure 1 to Figure 9 As shown, a civil engineering foundation pit construction reinforcement method mainly includes the following steps:

[0034] Step 1, docking operation, the docking mechanism 4 is used to manually dock and combine the bottom plate 2, and the bottom plate 2 is connected to form a template matching the length of the side wall of the foundation pit;

[0035]Step 2, positioning processing, manually laying the waterproof coiled material on the adjustment mechanism 3 through the positioning mechanism 6, and inserting the bottom plate 2 into a suitable position at the bottom of the foundation pit through the ground insertion mechanism 5;

[0036] Step 3, adjustment operation, adjust the waterproof membrane to the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com