Prefabricated building structure and construction method

A technology of building structure and prefabricated assembly, which is applied in the direction of building structure, architecture, stepped structure, etc., can solve the problem that the size of prefabricated stairs is not easy to modify.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

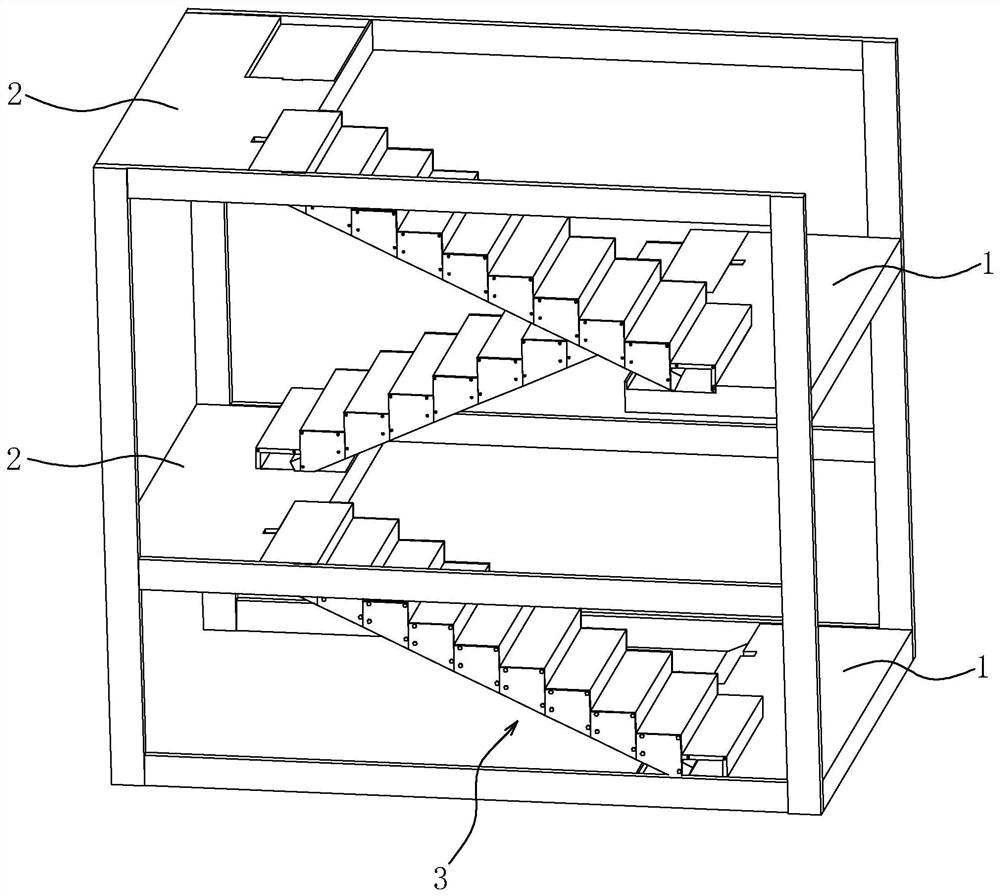

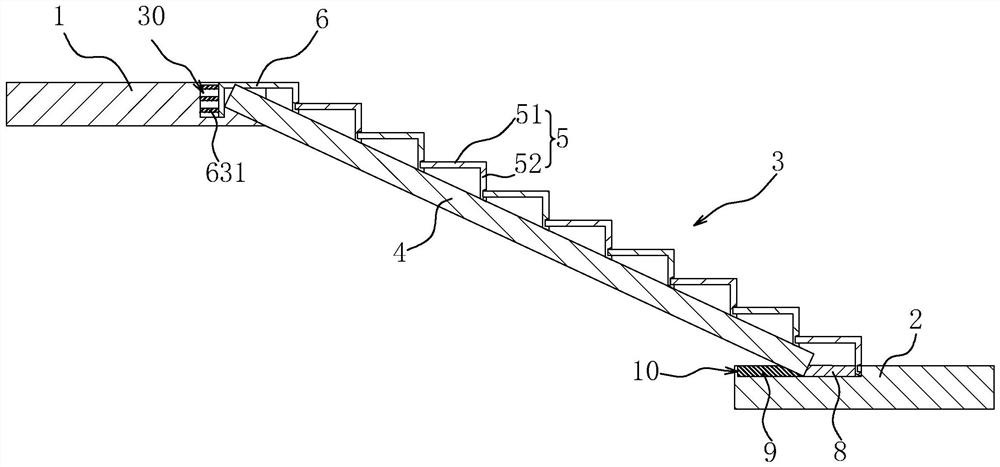

[0039] The embodiment of the present application discloses a prefabricated building structure. refer to figure 1 , the prefabricated building structure includes a floor body 1, and the floor body 1 serves as the floor of each floor. It also includes an intermediate platform 2 fixedly installed on the wall, the intermediate platform 2 is located between the two floor bodies 1, and the distance between the intermediate platform 2 and the two floor bodies 1 is equal. A staircase 3 for people to go up and down is connected between the floor body 1 and the middle platform 2 .

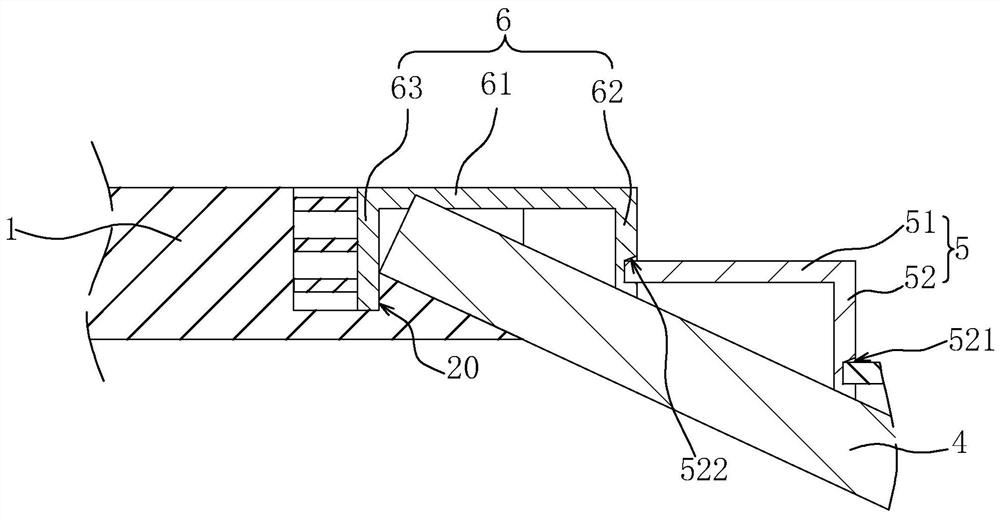

[0040] refer to figure 2 The staircase 3 includes a load-bearing plate 4 and a stepping piece 5 installed on the load-bearing plate 4 for people to step on. The load-bearing plate 4 is in a rectangular structure, and the load-bearing plate 4 can be a wooden board, a plastic plate or a steel plate. The load-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com