Industrial chemical pipeline manufacturing and machining method

A technology for chemical pipelines and processing methods, which is applied to manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of reducing the quality of welding connections, prone to sliding, and low degree of fixation, and achieves expansion of the scope of application and tightness of fit. Avoid and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

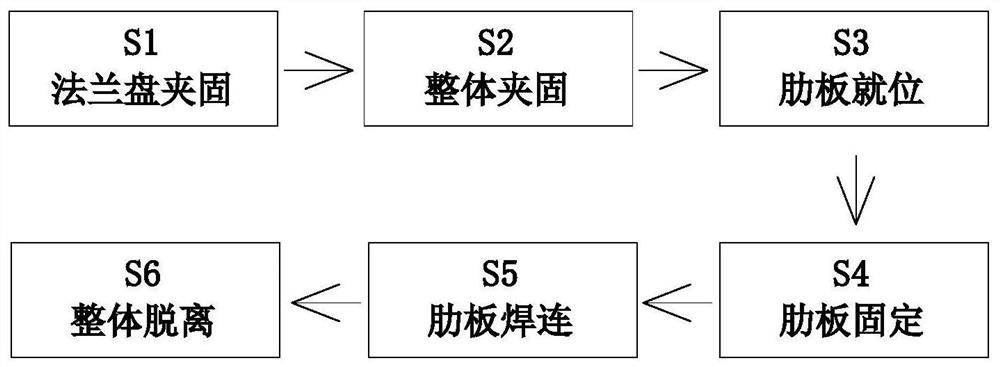

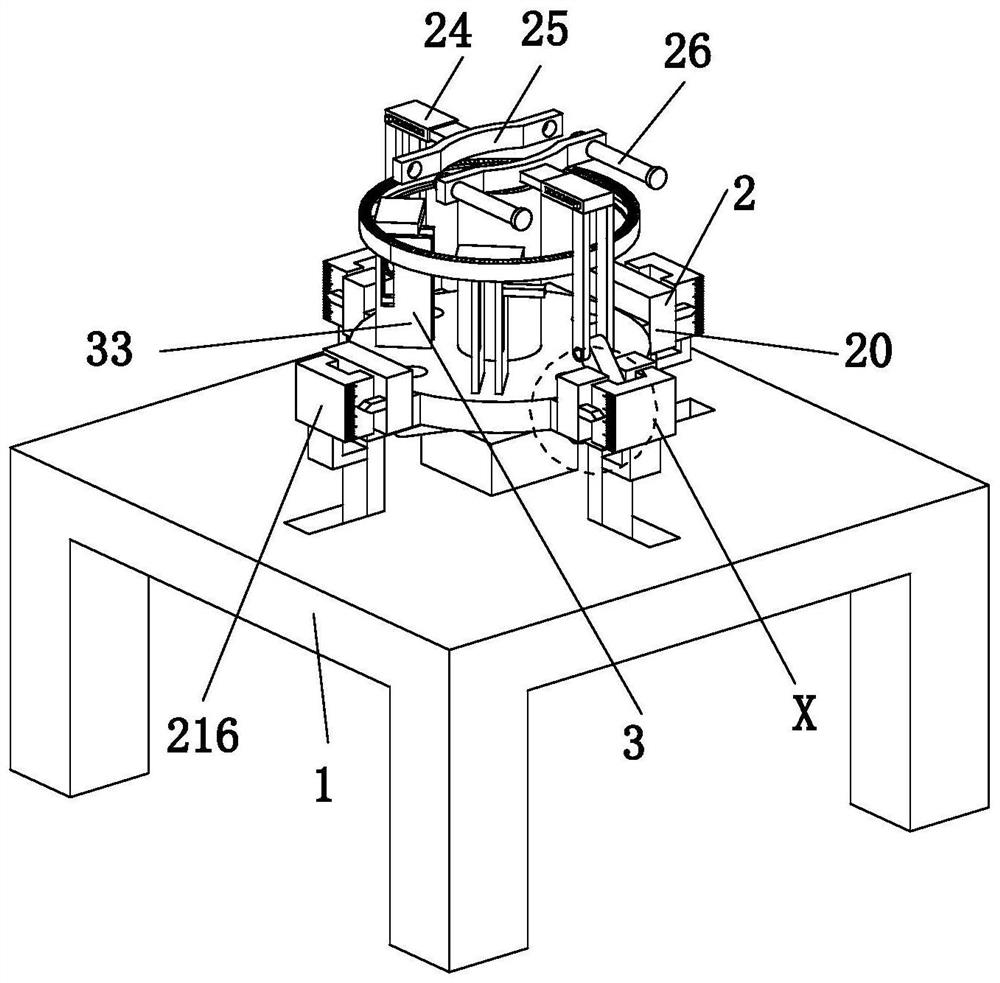

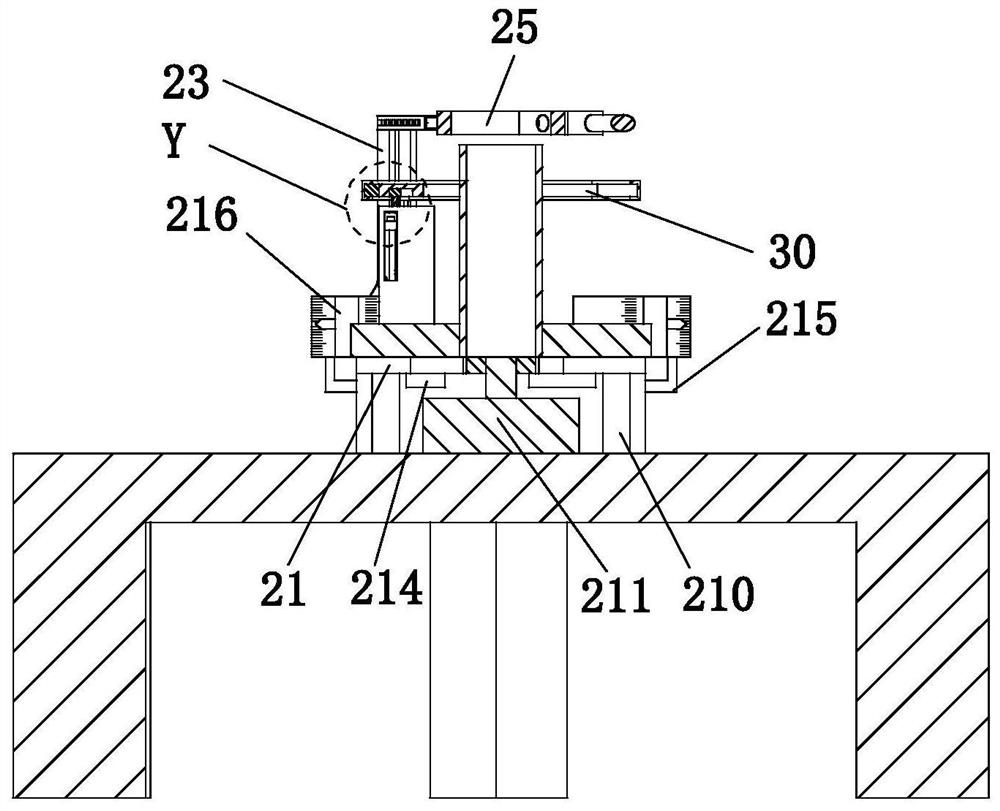

[0042] like Figure 1 to Figure 11 An industrial chemical pipeline manufacturing and processing method is shown, which uses an industrial chemical pipeline manufacturing and processing device. The industrial chemical pipeline manufacturing and processing device includes a workbench 1, a clamping mechanism 2 and an auxiliary welding unit 3, and adopts industrial chemical pipeline manufacturing and processing. The specific processing methods of the device for industrial chemical pipeline manufacturing and processing are as follows:

[0043] S1. Flange clamping: the flange is placed on the support plate 21 by manual means, and the lower splint 20 performs clamping treatment around it;

[0044] S2. Overall clamping: the connecting plate 23 is pressed down m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com