Viscous silica gel material

A silica gel and viscous technology, which is applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of not improving the elasticity of silica gel sheets, supplementing the viscosity of silica gel materials, and easily deforming silica gel sheets. , to improve elasticity, prevent cracking, enhance tensile strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

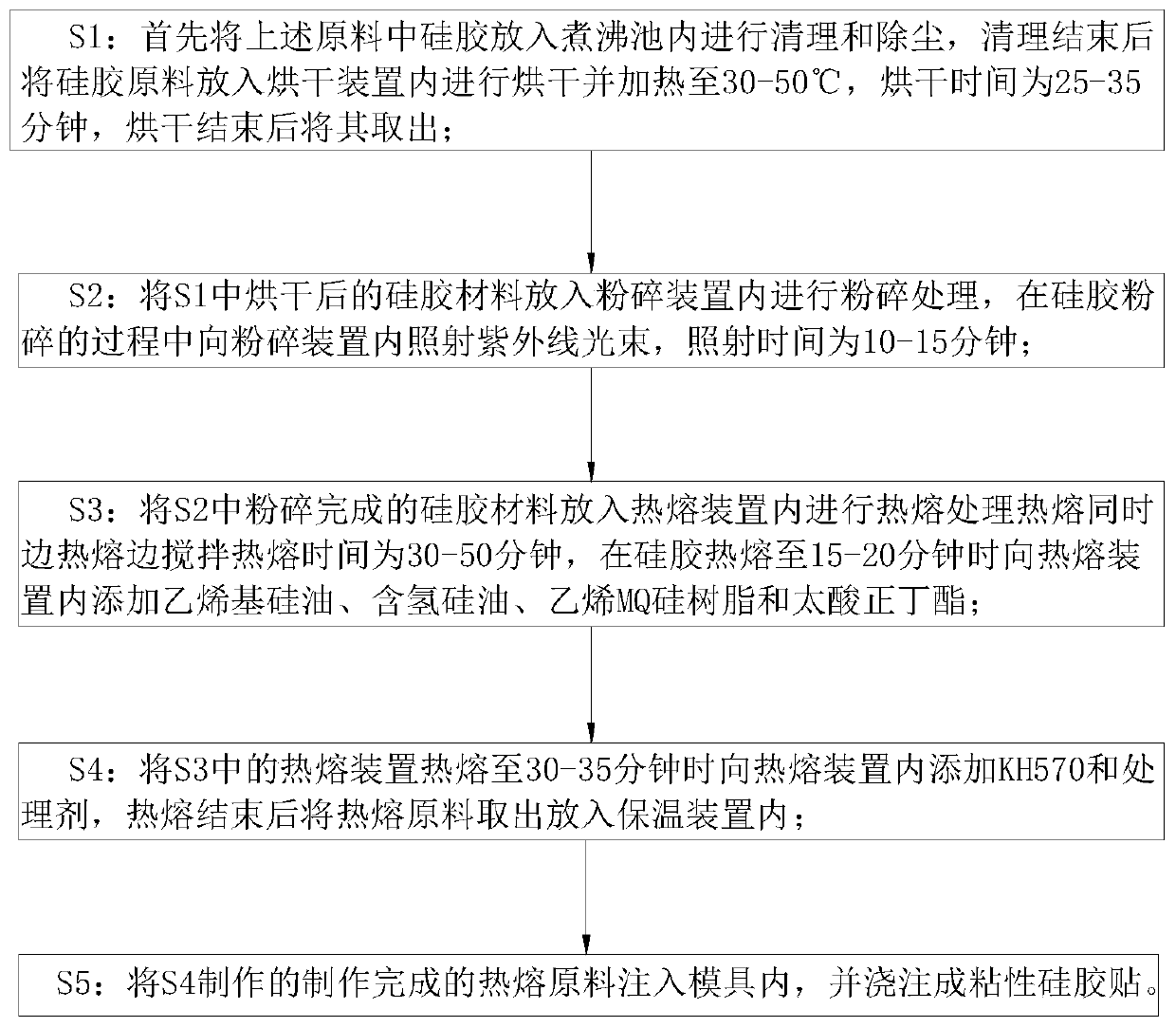

Method used

Image

Examples

Embodiment approach

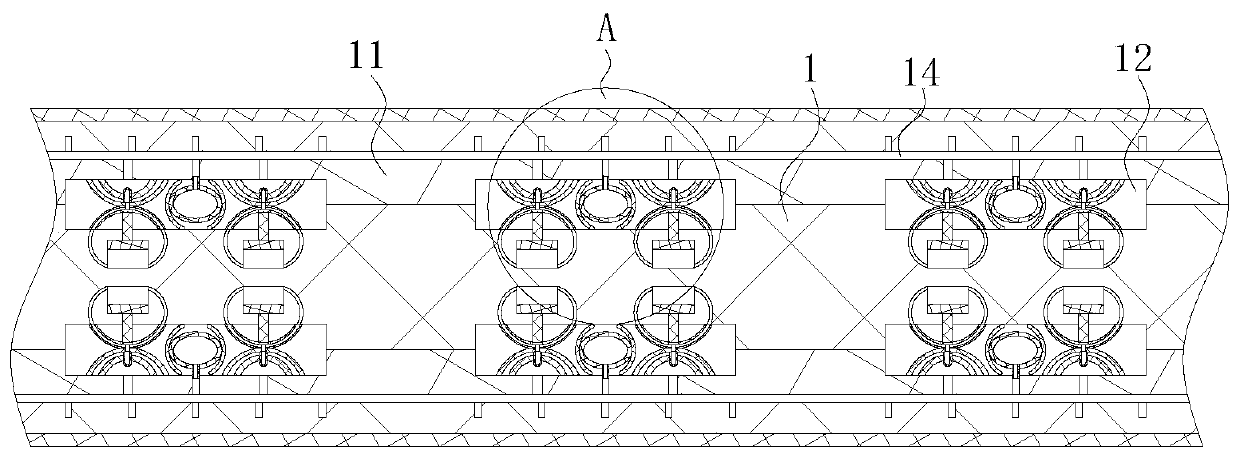

[0042] As an embodiment of the present invention, the raw materials also include inhibitors and Karlster catalysts;

[0043] Inhibitors in raw materials can reduce the polymerization reaction between raw materials in the present invention, so as to increase the rate of deterioration between raw materials, thereby improving the characteristics and quality of silica gel materials, and also have the role of stabilizers, which can make stable mixing between raw materials reaction, so as to prevent the molecular structure between the raw materials from changing, and the Karlster catalyst in the raw materials can catalyze the polymerization reaction between the raw materials in the present invention, so that the deterioration speed of the raw materials can be increased, and the characteristics of the silica gel material can be improved.

[0044] As an embodiment of the present invention, the treatment agent is a mixture of methyl vinyl silicone rubber and TPE material;

[0045] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com