Fixing structure for building electrical construction

A fixed structure and building electrical technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of unreliable fixing, time-consuming and labor-intensive, easy to shake, etc., and achieve the effect of reducing weight, improving stability and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

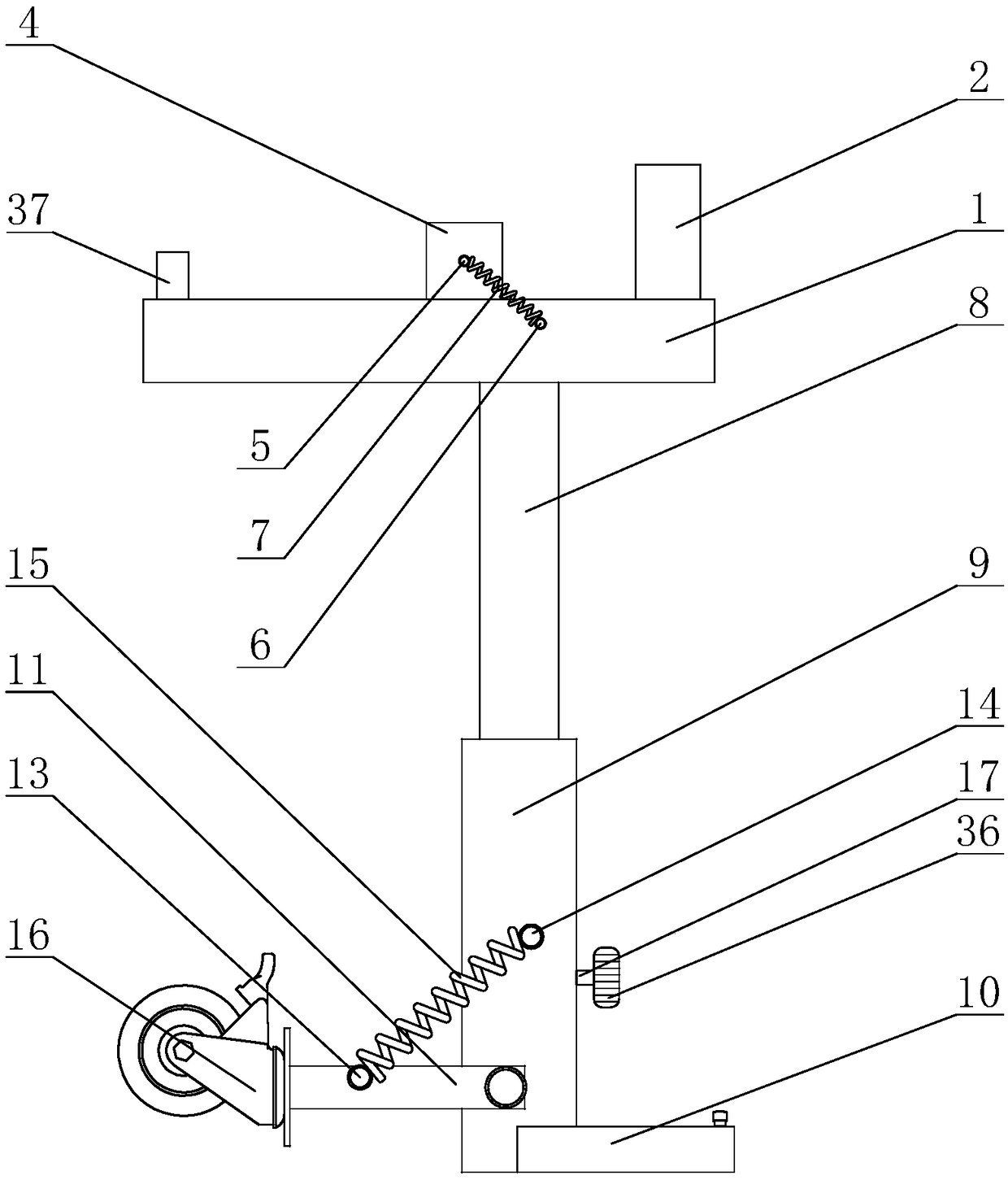

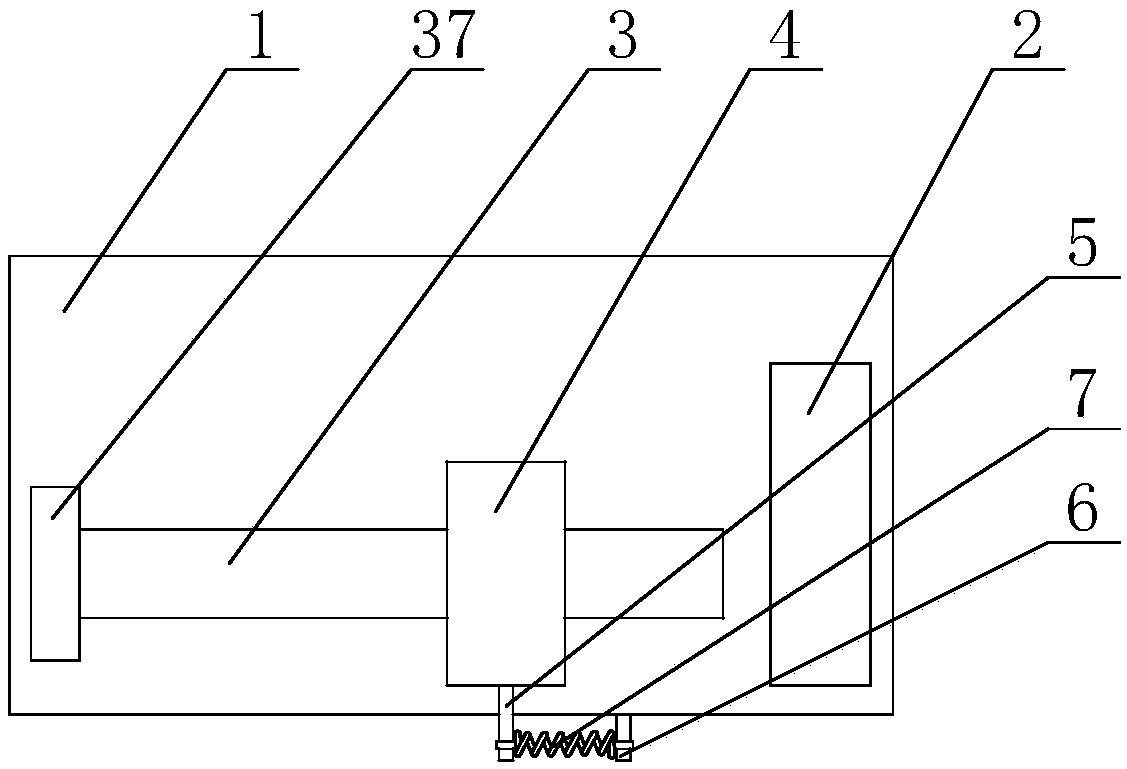

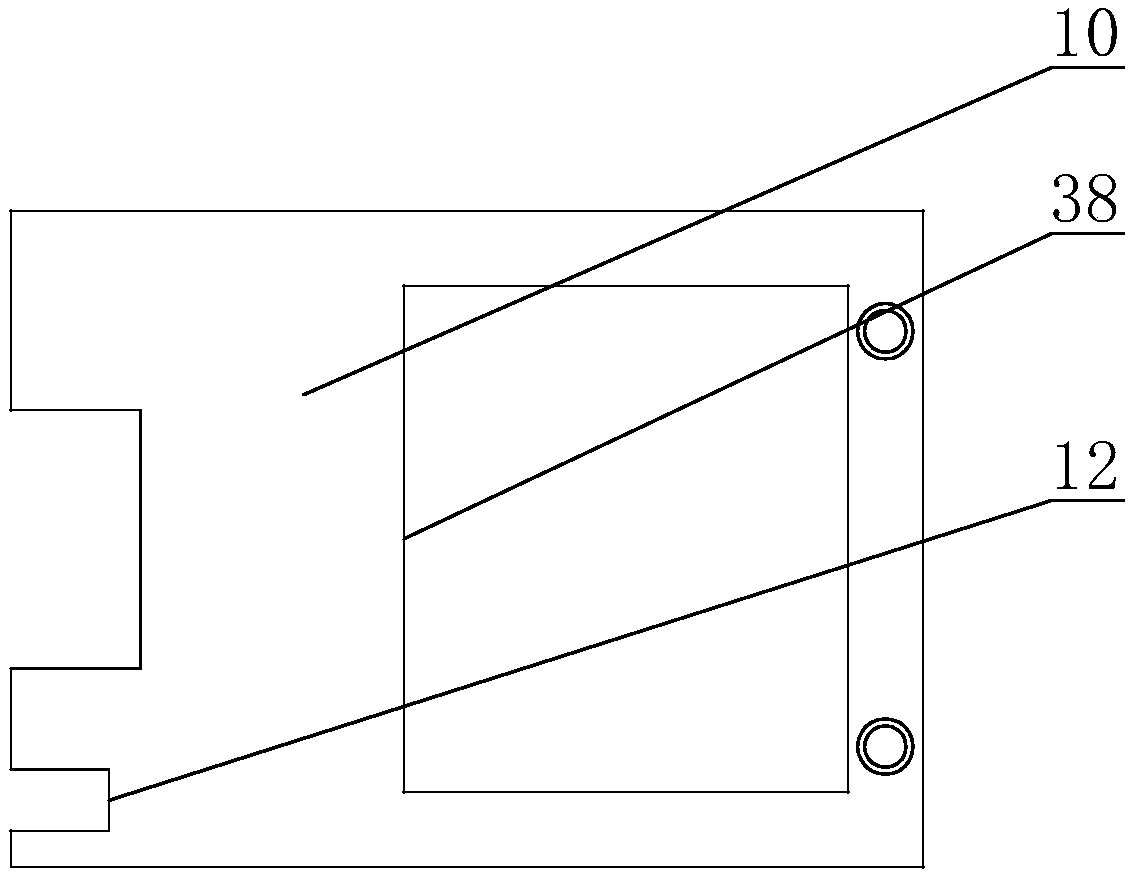

[0039] A fixed structure for electrical construction of a building, comprising a support plate 1, a fixing plate 2 is provided on the top side of the support plate 1, a slide groove 3 is provided on the top wall of the support plate 1, and a slider is provided in the slide groove 3, and A sliding plate 4 is provided at the top of the sliding block, and the sliding plate 4 is connected to the supporting plate 1 through a sliding block and a sliding groove 3 in a sliding manner. The sliding plate 4 is provided with a first connecting rod 5 on one side of the supporting plate 1. A second connecting rod 6 is provided. A first tension spring 7 is provided between the second connecting rod 6 and the first connecting rod 5. The second connecting rod 6 and the first connecting rod 5 are both connected to the first tension spring. 7 is hinged, the fixed plate 2 and the sliding plate 4 are located in the support plate 1 on the opposite side of the first tension spring 7, the bottom of the...

Embodiment 2

[0041] In this embodiment, on the basis of embodiment 1, the lifting device is replaced with a motor 27, which is fixedly connected to the bottom wall of the fixed rod 9, and a coupling 28 is provided on the output shaft of the motor 27. The shaft 28 is provided with a second screw 29 at one end away from the output shaft of the motor 27. A second nut 30 is mounted on the second screw 29. The second nut 30 is a cylindrical nut. The second guide rod 31 is provided with a second sliding block 32 at one end away from the second nut 30, and a second slide rail 33 is provided on the inner wall of the second fixed rod 9, and the second slide rail 33 is The sliding block 32 is adapted to each other, and a second connecting plate 34 is provided at the top of the second nut 30, and the second connecting plate 34 is fixedly connected to the bottom end of the sliding rod 8. The beneficial effect of this embodiment is that the invention adopts the rotation of the motor to adjust the liftin...

Embodiment 3

[0043] In this embodiment, on the basis of embodiment 1, the first bevel gear on the rotating rod is replaced with a spur gear, and the second bevel gear, the first screw, the first nut, the first slider, and the first slide rail are removed. Equivalent structure, a straight rack is provided on one side of the spur gear, the top of the straight rack is directly connected with the sliding rod, and the sliding lift of the sliding rod is realized through the gear rack structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com