Tire X-ray image impurity defect detection method

A defect detection and X-ray technology, which is applied in the field of impurity defect detection in tire X-ray images based on improved YOLOv4-tiny, can solve the problems of defects and low background detection, imperfection, and low efficiency of artificial naked eye detection, so as to avoid defect errors Judgment, the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

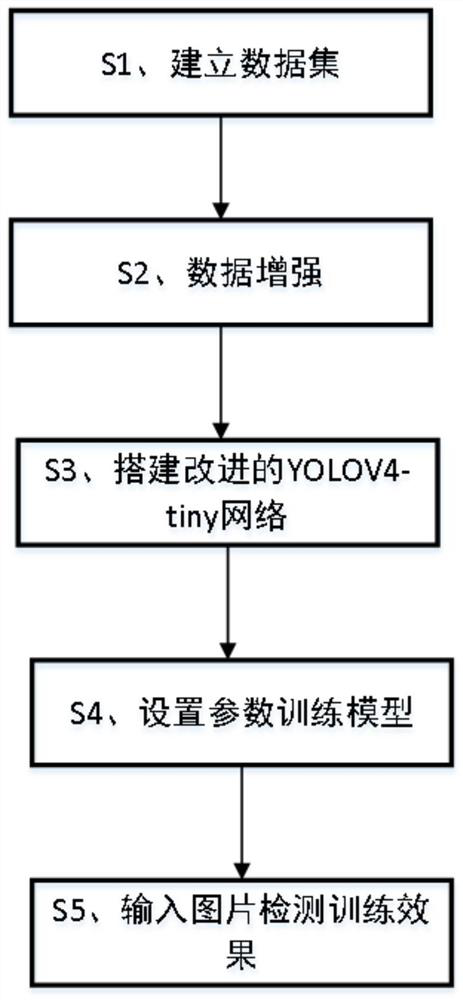

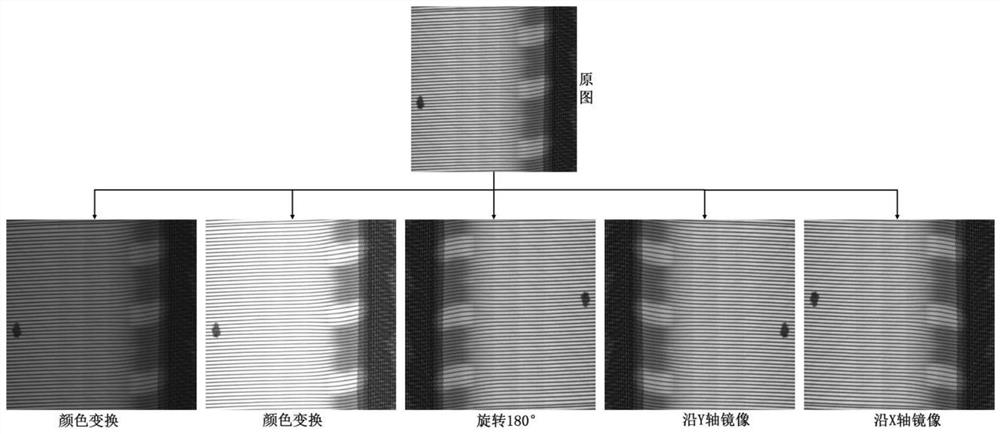

[0059] Such as Figure 1-14 As shown, the present invention provides a kind of tire X-ray image impurity defect detection method based on improving YOLOv4-tiny, comprises the following steps:

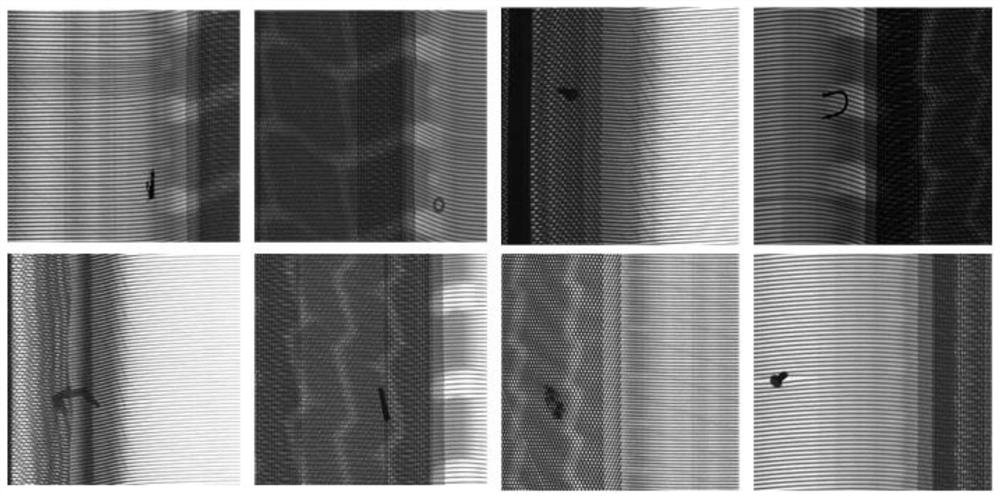

[0060] S1. Intercepting 416*416 images containing impurities from the X-ray tire image of 2469*11400 collected by the X-ray machine to establish a data set;

[0061] S11. Use an X-ray machine to scan the inner circle of the tire at 360°. Due to the differences in the material and density of the material and density between the impurities and the normal tread, the degree of absorption of the rays will be different, resulting in the uniformity of the rays passing through the workpiece. Form a light and dark image on the film, and receive the image through a computer. The image is a tire X-ray image with a size of 2469*11400. These images include normal and defective tire X-ray images, and the tires containing impurities and defects are selected from these images. X-ray images, intercepti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com