Ultrahigh-voltage and extra-high-voltage multi-break quick vacuum circuit breaker topological structure

A vacuum circuit breaker and topology technology, applied in high voltage air circuit breakers, high voltage/high current switches, circuits, etc., can solve the problems of excessive inrush current, long breaking time, circuit breaker failure, etc., and reduce model selection. requirements, the effect of improving the rated current capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

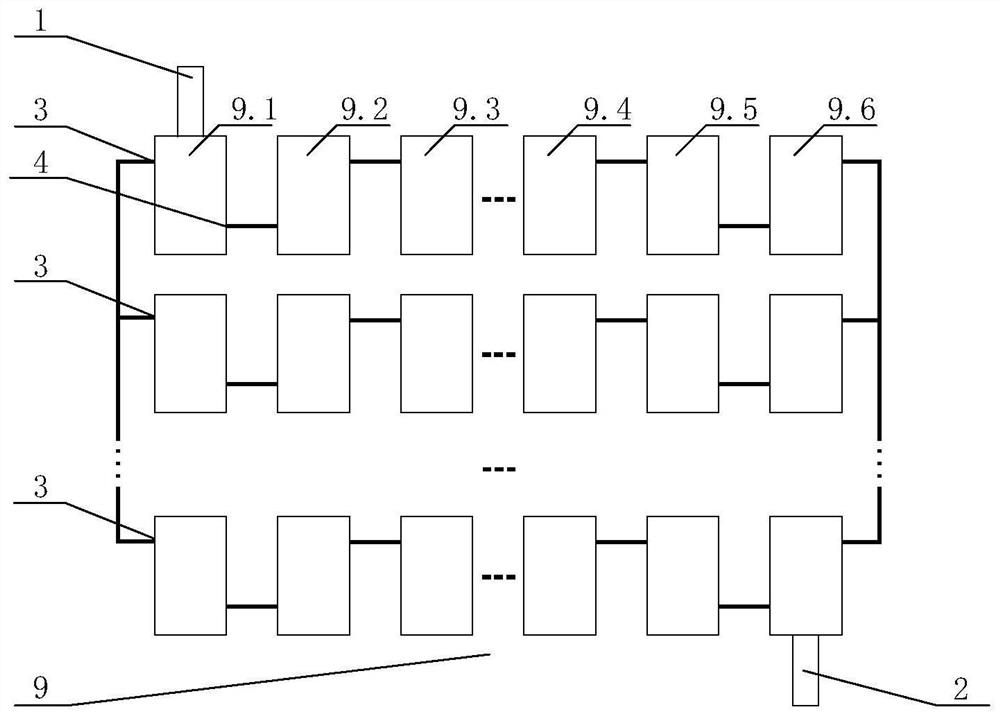

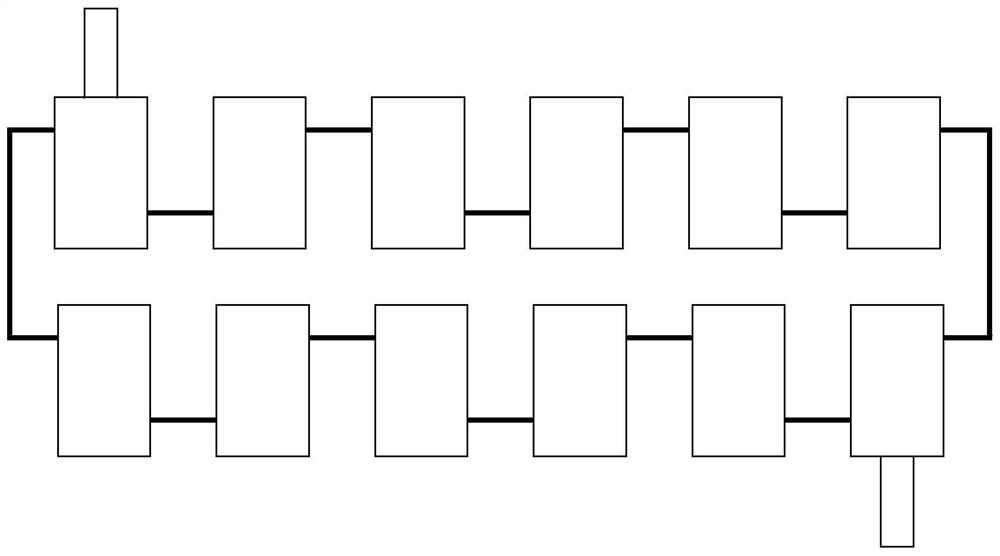

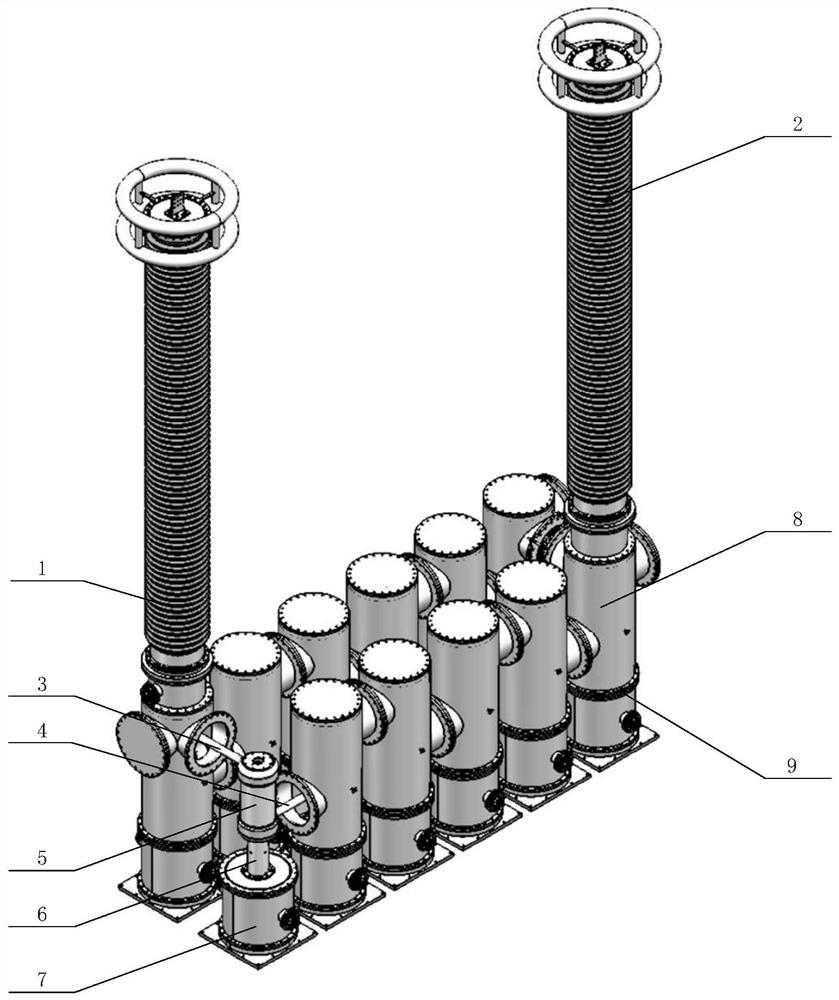

[0018] Such as figure 1 As shown, the topological structure of a super-high voltage and ultra-high voltage multi-fracture fast vacuum circuit breaker of the present invention includes a plurality of identical fast vacuum circuit breaker units 9, and adopts a topological connection structure of series first and then parallel. Each parallel branch is formed by a plurality of identical circuit breaker units in series. Among them, the conductive copper rods 3 of the static outlet lines of the arc extinguishing chamber at the first end of all parallel branches are connected to each other, and the first one is connected in parallel. The top bus bar lead-out port of the first fast vacuum circuit breaker unit 9.1 in the branch circuit is connected to the first lead-out bushing 1; in each parallel branch circuit, the first fast vacuum circuit breaker uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com