A remote operation and maintenance device for CNC automation equipment based on big data

A technology of automation equipment and big data, which is applied in the construction parts of electrical equipment, electrical equipment shell/cabinet/drawer, support structure installation, etc. With remote monitoring function and other issues, it can achieve the effect of adding free movement monitoring function, ensuring the convenience of operation and maintenance, and ensuring the stability of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

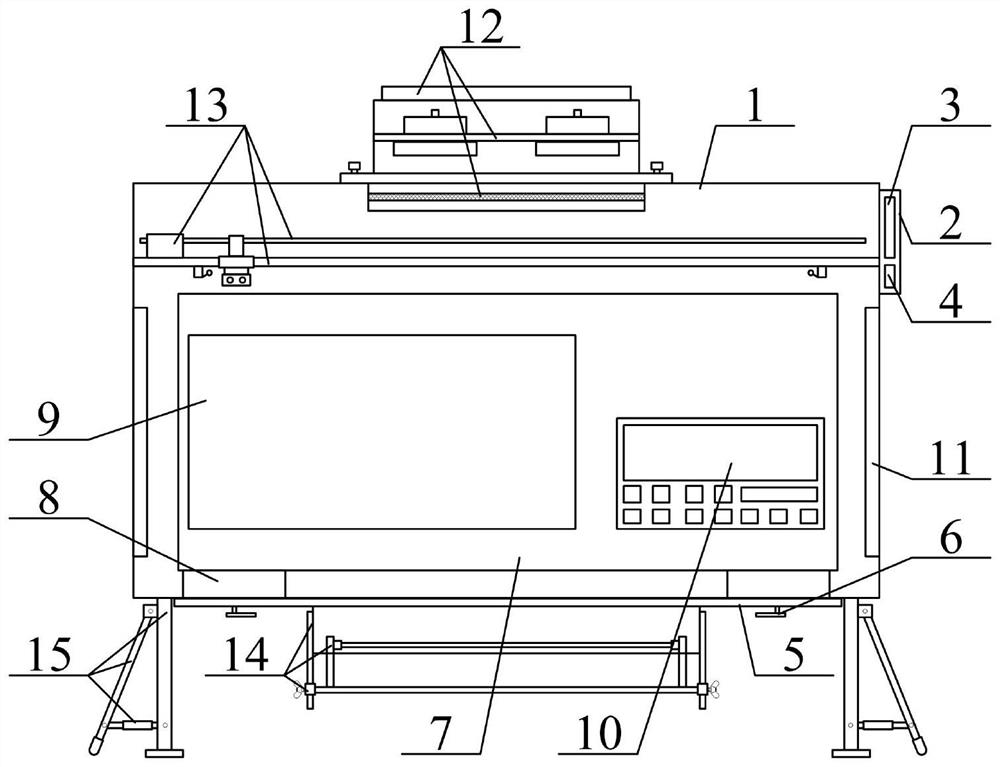

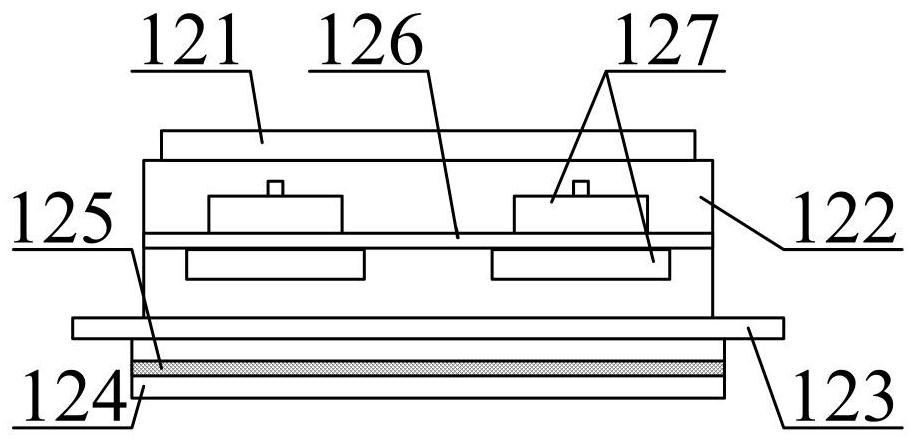

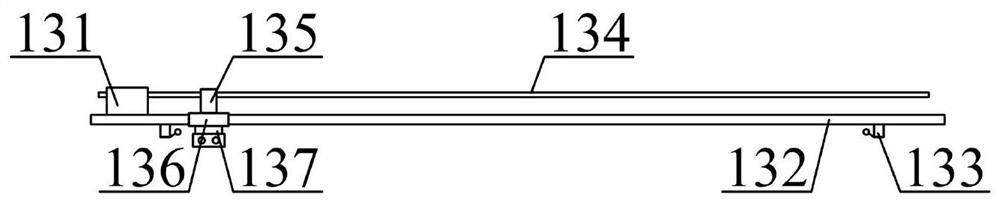

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a remote operation and maintenance device for CNC automation equipment based on big data includes an operation and maintenance chassis 1, a cabinet 2, a host computer 3, a remote monitoring module 4, a bottom cover 5, disassembly bolts 6, and a CNC automation equipment body 7. Vibration cushion block 8, display screen 9, control panel 10, cooling plate 11, filter type heat dissipation exhaust tube structure 12, free-moving internal monitoring machine structure 13, lifting adjustment auxiliary searchlight operation and maintenance tube structure 14 and adjustable The ground supports the protective rod structure 15, the upper right side of the operation and maintenance cabinet 1 is screwed to the cabinet 2; the upper and lower parts of the inner side of the cabinet 2 are screwed to the host 3 and the remote monitoring module 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com