Milling machine cleaning device

A cleaning device, milling machine technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of inability to clean and collect small waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

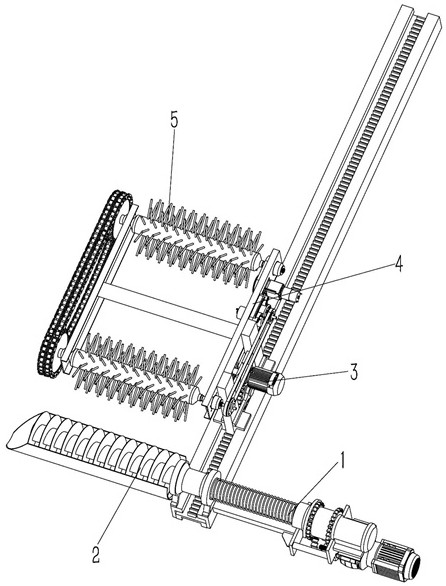

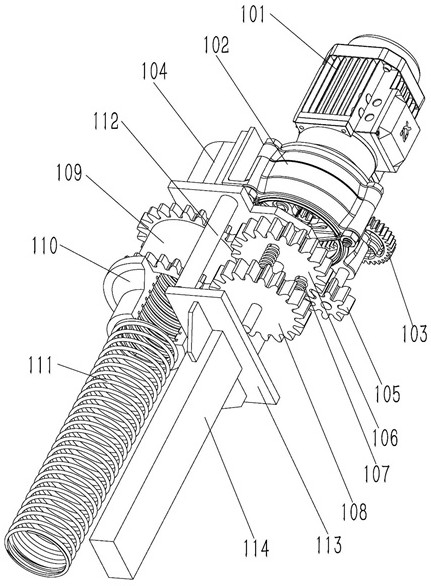

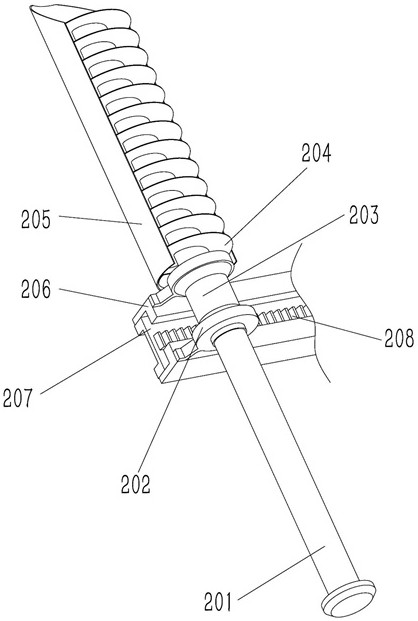

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The milling machine cleaning device shown includes a slag collecting power mechanism 1 , a slag conveying mechanism 2 , a traveling transmission mechanism 3 , a rotating power mechanism 4 and a cleaning roller mechanism 5 .

[0023] Slag collecting power mechanism 1 includes: screw nut 110 and support vertical plate 114; slag conveying mechanism 2 includes: rotating shaft 201, side guide lock block 206 and travel rack 208; travel transmission mechanism 3 includes: vertical column 301 , guide side chute 302 and travel gear 304; Rotation power mechanism 4 comprises: left side fixed large plate 401, upper end roller connecting flange 404 and lower end roller connecting flange 416; Cleaning roller mechanism 5 includes: connecting rolling shaft 502 and roller The cleaning roller 503; the support vertical plate 114 is fixedly installed on the side guide lock block 206, the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com