A follow-up material receiving and packing equipment for acrylic advertising characters

A kind of advertising word and follow-up technology, which is applied in the field of machinery manufacturing and processing, can solve the problems of small parts loss and other problems, and achieve the effect of avoiding lost parts, avoiding safety hazards, and simplifying the process of retrieving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

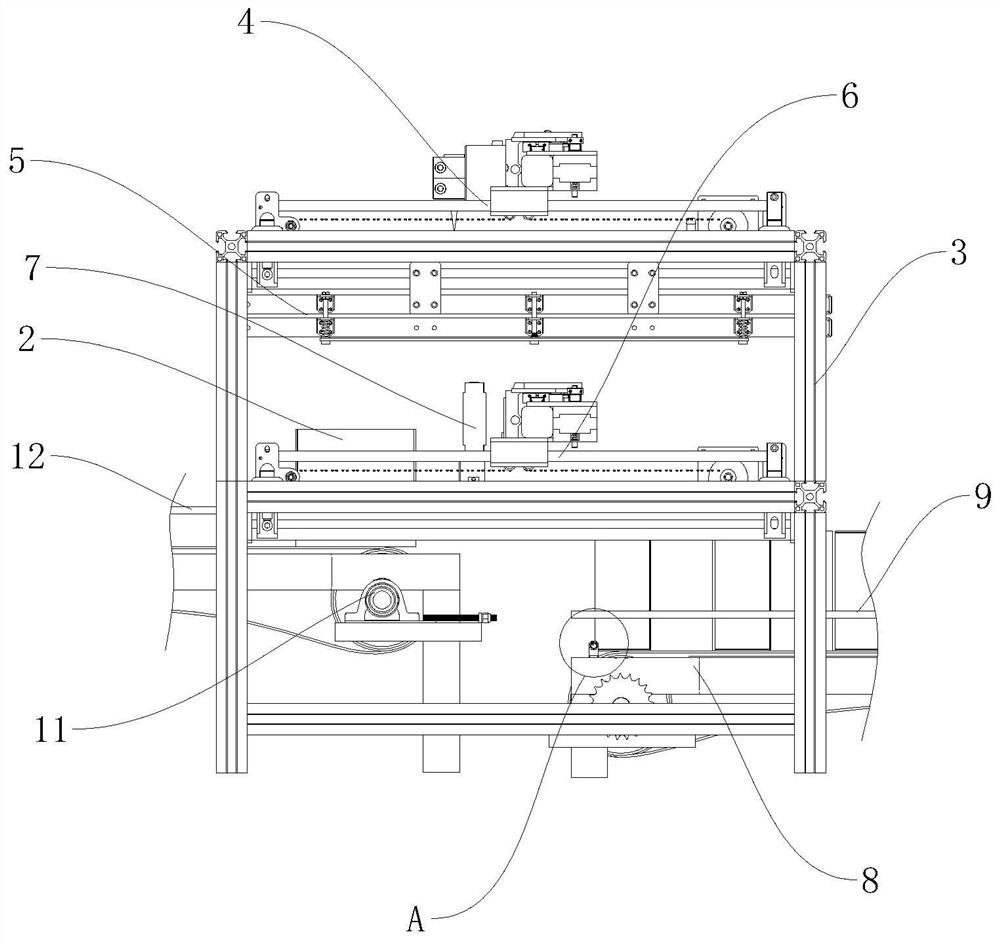

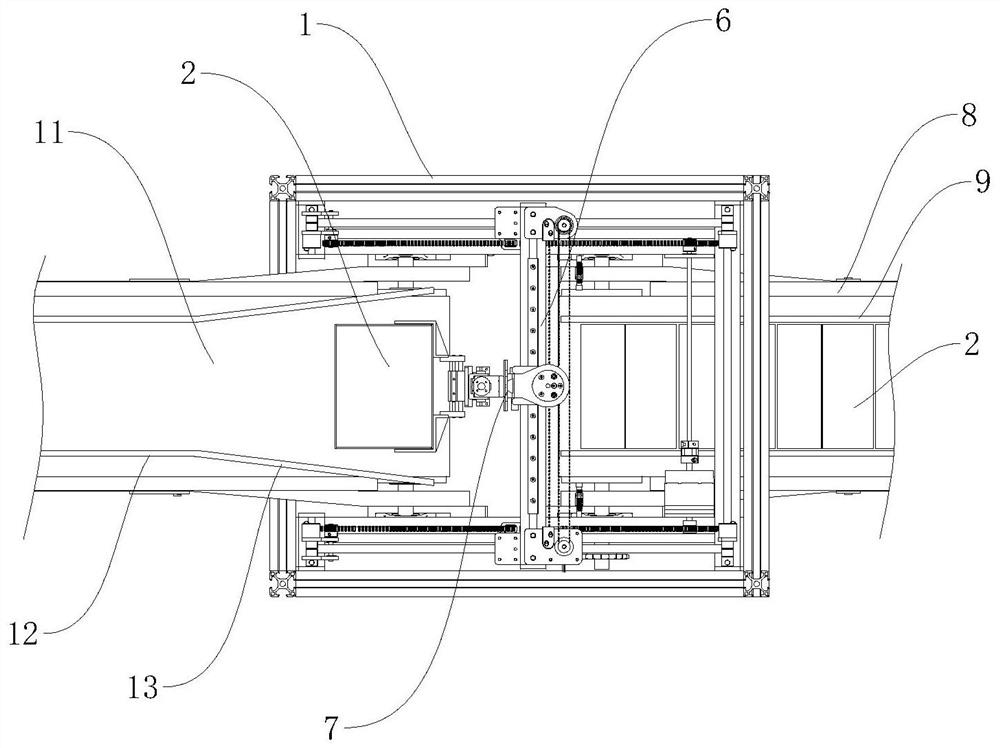

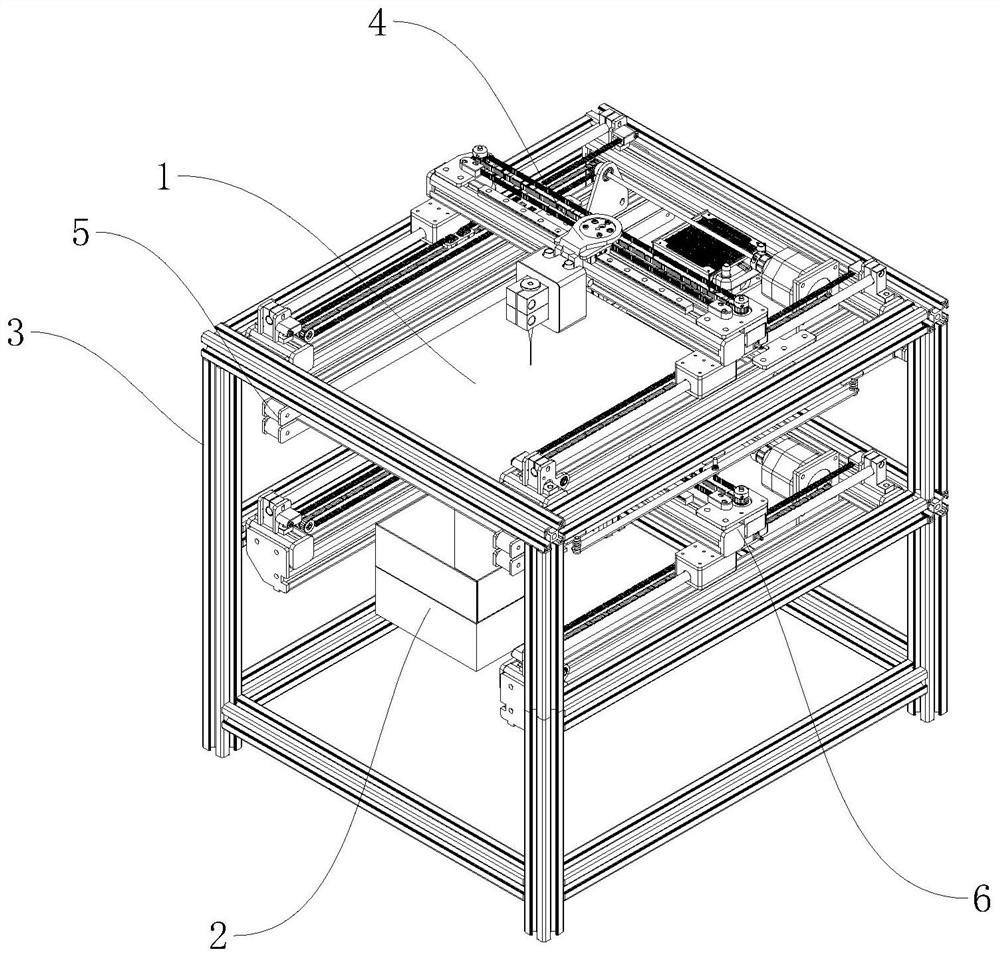

[0053] refer to Figure 1 to Figure 8 Shown is a follow-up material receiving and packing equipment for acrylic advertising words, including:

[0054] The main body 3 of the rack is composed of several aluminum profiles, and has upper and lower spaces;

[0055] The cutting assembly 4 is fixedly arranged in the upper space of the frame main body 3, and is used for font cutting on the acrylic sheet 1;

[0056] The sheet feeding mechanism 5 is located in the upper space of the frame main body 3 and is fixedly arranged just below the cutting assembly 4, and is used for conveying the acrylic sheet 1 to the directly below the cutting assembly 4;

[0057] The two-axis moving assembly 6 is fixedly arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com