Measureable container

A container and bottle technology, applied in the distribution of powder materials, etc., can solve the problems of unsanitary, complicated operation, pollution, etc., achieve accurate measurement, simple material taking process, and reduce the risk of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

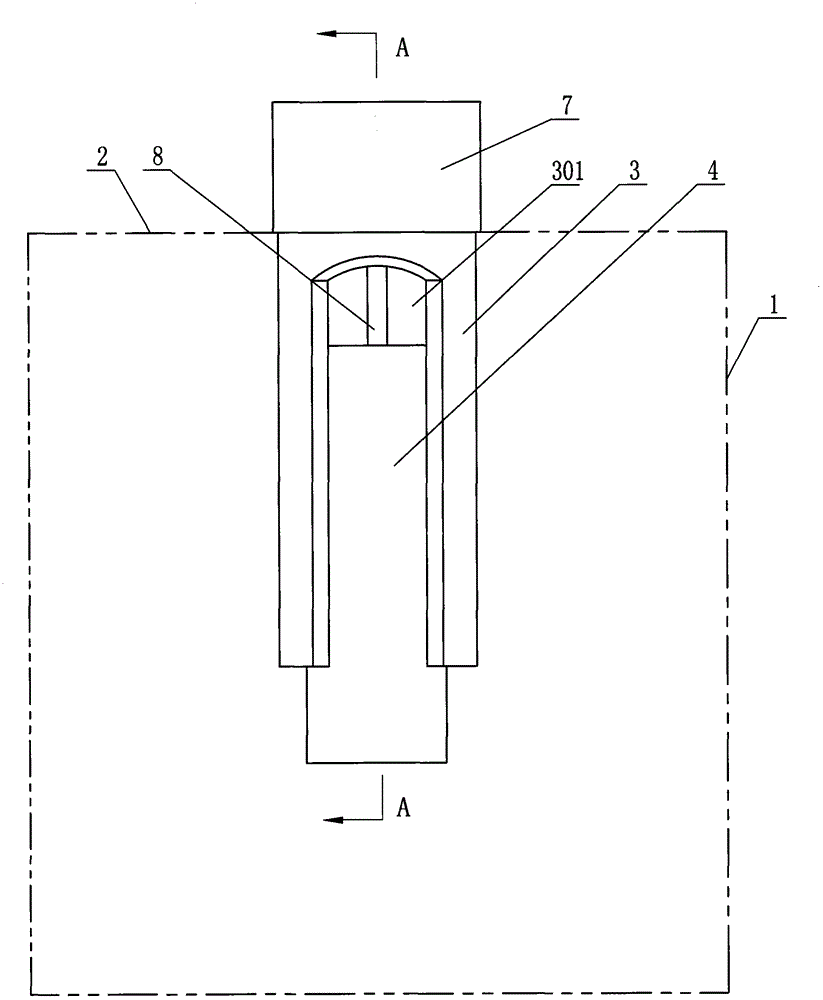

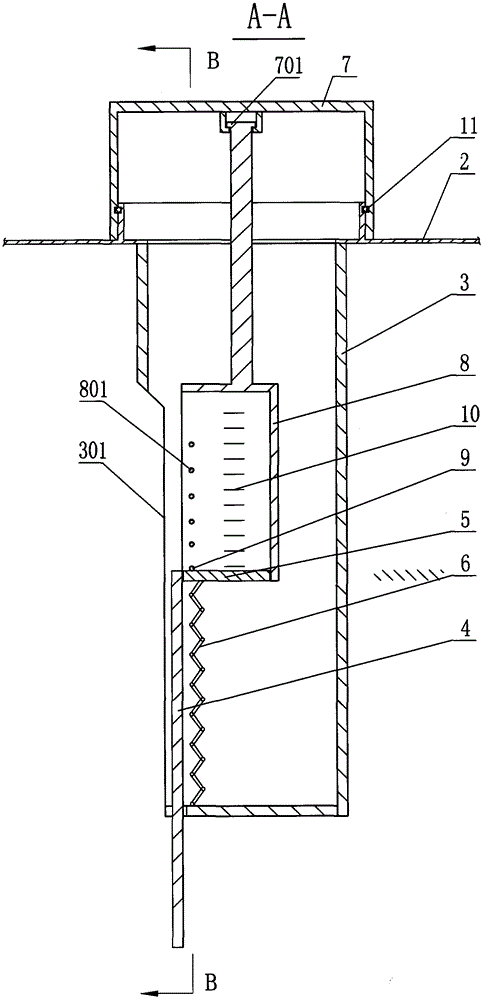

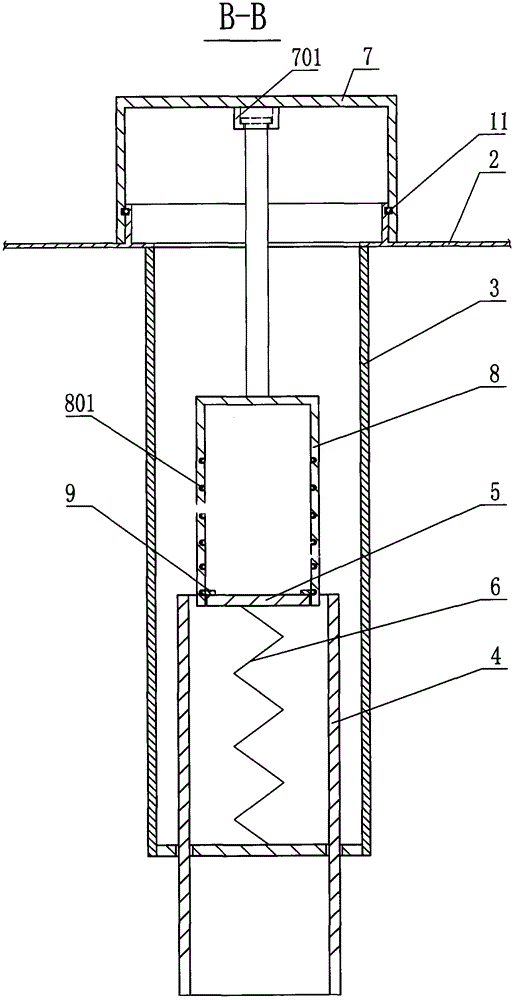

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0024] See figure 1 , figure 2 , image 3 , the present invention includes a tank body 1 and a tank cover 2 that closes or closes the opening of the tank body 1, the tank cover 2 is provided with a through axial opening, the metering bottle body 3 is integrally formed with the tank cover 2 and is integrated with the The axial opening communicates, the metering bottle body 3 is located in the tank body 1, and the axis of the metering bottle body 3 is parallel to the axis line of the tank body 1, and the wall of the metering bottle body 3 has a material inlet and outlet 301 extending in the axial direction. The material inlet and outlet 301 communicates with the interior of the tank body 1. A slide cover 4 is slidably connected to the material inlet and outlet 301. The slide cover 4 is used to open or close the material inlet and outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com