Silage cutting and carrying device

A technology of handling device and silage material, applied in the field of silage material cutting and handling device, can solve the problems of low efficiency, large loss of silage material, cutting dust and material splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

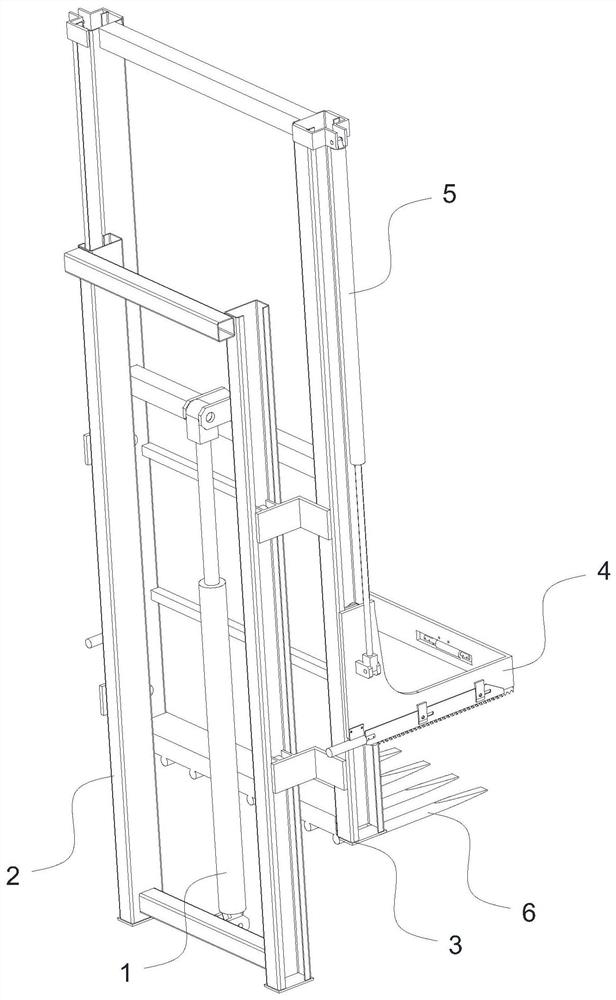

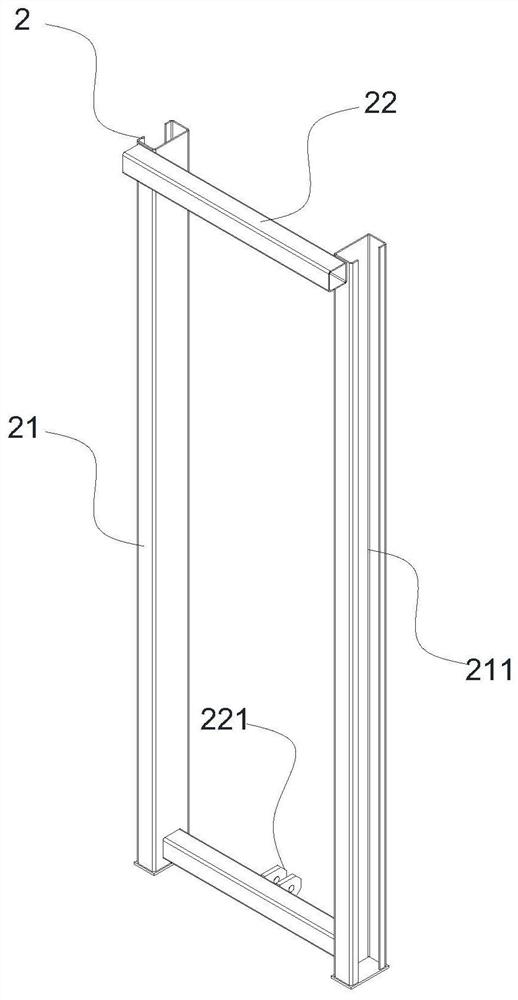

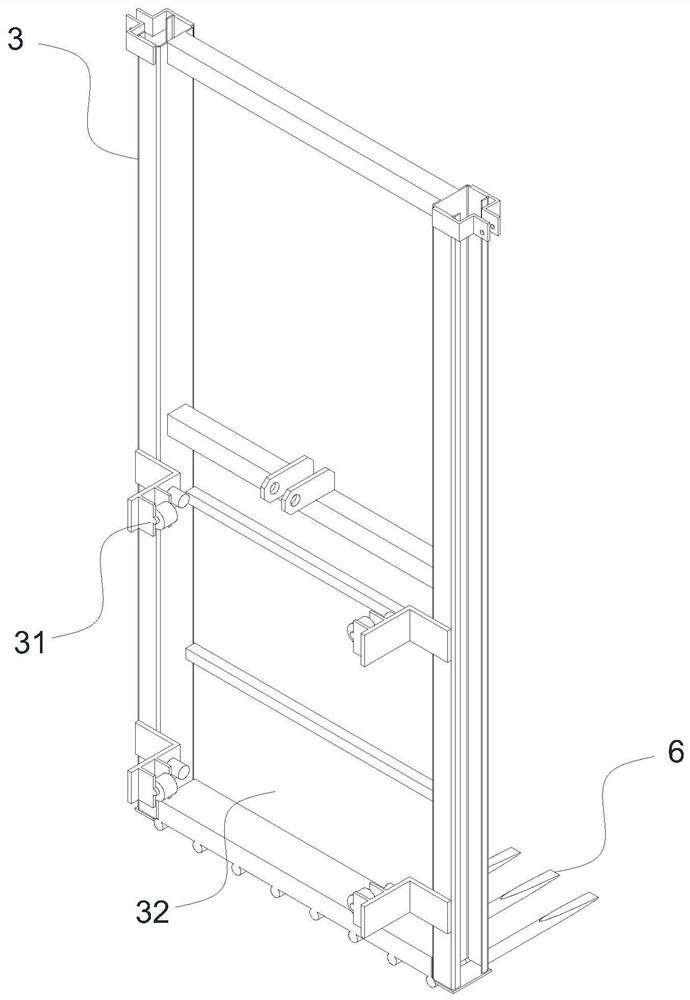

[0031] Such as Figure 1-Figure 6 As shown, a silage cutting and transporting device includes an inner drive cylinder 1 , an inner frame 2 , an outer frame 3 , a saw frame assembly 4 and an outer drive cylinder 5 .

[0032] Inner driving oil cylinder 1 is fixedly installed on inner frame 2, and outer frame 3 is slidably installed on inner frame 2, and inner driving oil cylinder 1 drives outer frame 3 to run up and down along inner frame 2, and outer frame 3 bottoms are fixed with a plurality of fork rods 6. The outer driving cylinder 5 is fixedly installed on the outer frame 3, the saw frame assembly 4 is slidably installed on the outer frame 3, and the outer driving oil cylinder 5 drives the saw frame assembly 4 to run up and down along the outer frame 3; the saw frame assembly 4 includes a fixed saw frame 41, and the fixed saw Both sides of the frame 41 are provided with outer pulley devices 42, and the outer pulley devices 42 run up and down along the two sides of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com