A cutting and conveying device for architectural glass

A technology for architectural glass and conveying devices, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of fragility, cutting position offset, etc., to ensure smoothness, prevent cutting position offset, and high safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

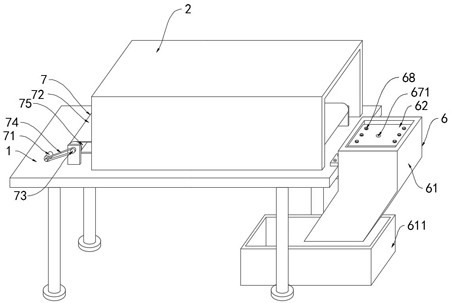

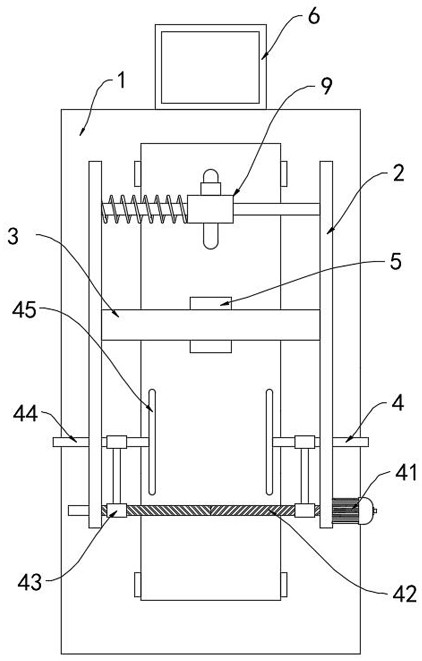

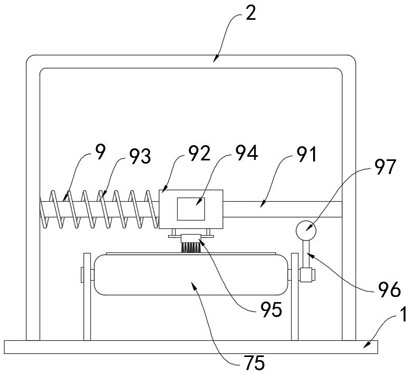

[0027] Refer to attached figure 1 , a cutting and conveying device for architectural glass, comprising a workbench 1, a C-shaped support 2 is welded and fixed on the upper surface of the workbench 1, a cutting frame 3 is installed in the C-shaped support 2, and a cutting knife is installed on the cutting frame 3 In the assembly 5, a cleaning mechanism 9 is provided in the C-shaped support 2, and a disconnecting mechanism 6 is provided on one side of the workbench 1.

[0028] Refer to attached figure 1 Specifically, the upper surface of the workbench 1 is fixedly connected with a conveying mechanism 7 for transporting architectural glass. The conveying mechanism 7 includes a conveying motor 71, a pulley 73, a belt 74, a conveying roller 75 and a conveying belt 72, and the two conveying rollers 75 A conveyor belt 72 is sleeved on the side wall, and one of the conveyor rollers 75 is coaxially fixed with the pulley 73, and the output end of the conveyor motor 71 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com