Stainless steel pipe cutting clamp

A technology for stainless steel pipes and fixtures, which is applied in the direction of shearing devices, manufacturing tools, maintenance and safety accessories, etc. It can solve the problems of limited application range, unstable clamping, high temperature, etc., and achieves wide application range and easy recycling. , high automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

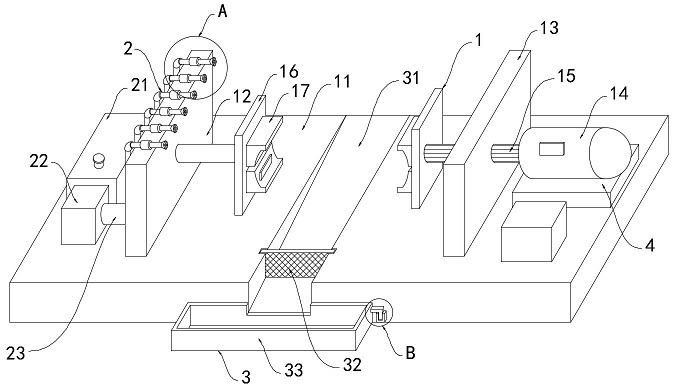

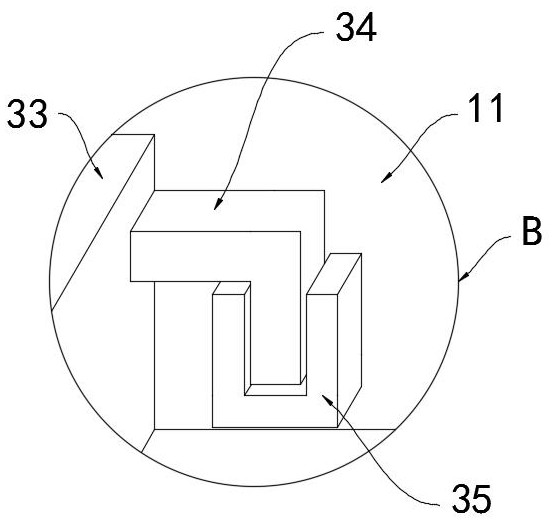

[0028] Such as Figure 1-5 As shown, a stainless steel pipe cutting fixture, including:

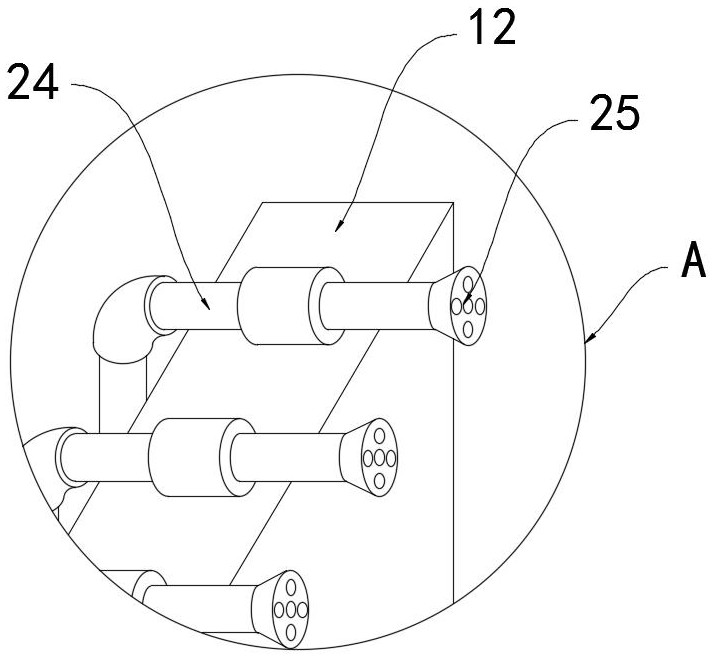

[0029] The clamping mechanism 1 includes a workbench 11, a first baffle 12, a second baffle 13, a cylinder 14, a push rod 15, two mounting plates 16 and two clamping parts 17, the first baffle 12 and the second baffle The plates 13 are vertically and fixedly connected to the upper surface of the workbench 11, one of the mounting plates 16 is fixedly mounted on the side wall of the first baffle plate 12 through a connecting rod, and the other mounting plate 16 is fixedly connected to the push rod 15, and the push rod 15 runs through Slidingly connected in the second baffle plate 13, the cylinder 14 is fixedly installed on the workbench 11. It is worth mentioning that the bottom pad of the cylinder 14 is provided with an air cushion 4, and the steel pipe vibrates during the cutting process, and the vibration is transmitted to the cylinder 14 At the position, the air cushion 4 can play a go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com