Alternative Thermal Coupled Process for Vacuum Induced Air for Ethylene Glycol Distillation Separation

A technology for rectification separation and ethylene glycol, which is applied in heat exchangers, chemical industry, indirect heat exchangers, etc., can solve problems such as affecting the stability of heat pump system operation, difficulty in control system design and operation, and fluctuations in boiling point difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

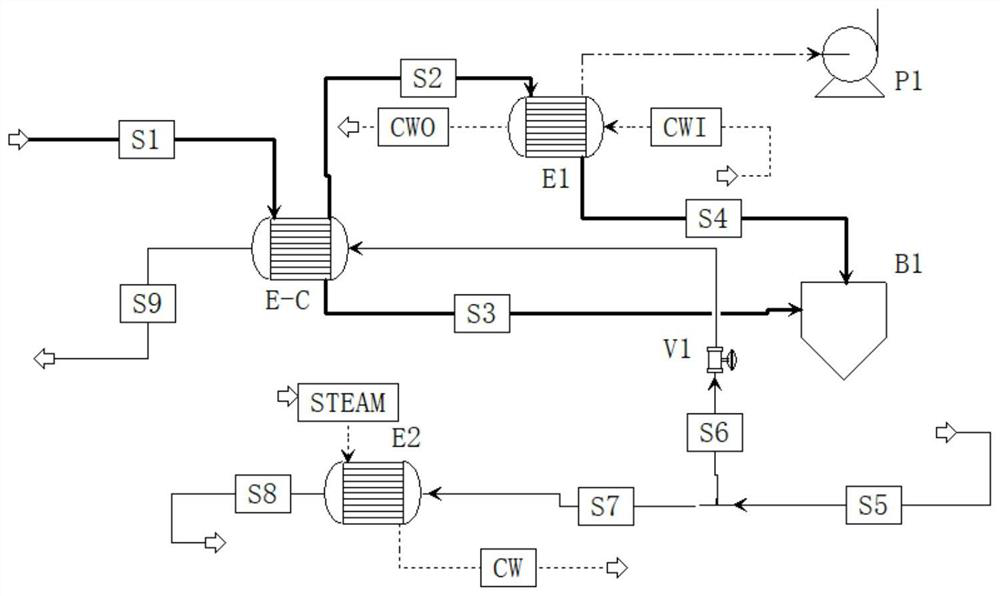

Embodiment 1

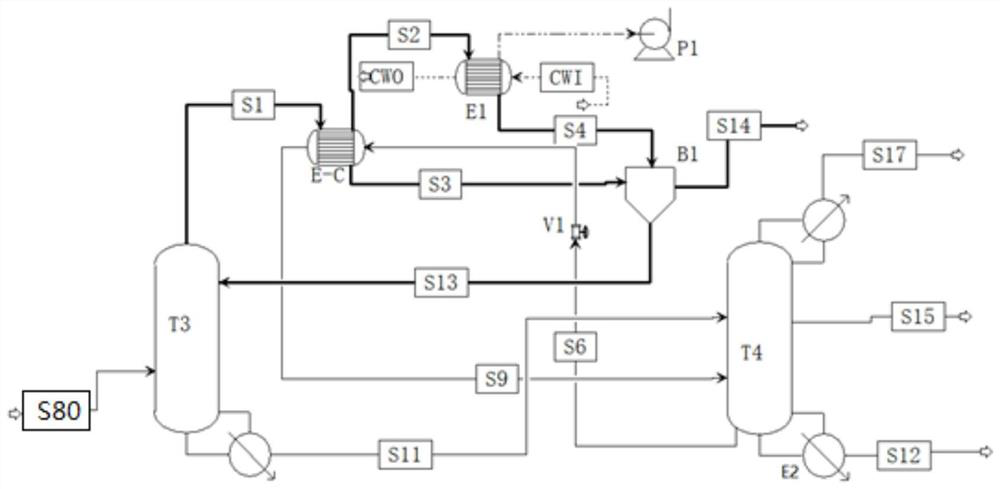

[0039] as Figure 2As shown, the stream strand S80 extracted from the bottom of the deoxate tower enters the debutanol tower T3, Debutanol tower T3 top pressure 0.4atm, temperature 162 °C, debutanol tower T3 top of the binary alcohol steam S1 has been connected in series coupling heat exchanger E-C and condenser E1 to achieve full condensation, condenser E1 uses circulating water CWI to ensure the cooling load of the top of the debutanol tower and meet the cooling load required for operation process regulation, coupling heat exchanger E-C and condenser E1 generated by the condensate into the condensate storage tank B1, the extraction of mixed diol product S14, the rest of the S13 backflow to the top of the debutanol tower T3, debutanol tower T3 bottom to extract flow stockS11 into the ethylene glycol refining tower T4 , ethylene glycol refining tower T4 top pressure 0.1atm, with liquid side line S15 to extract the product ethylene glycol S15, to the top steam flow S17 to extract th...

Embodiment 2

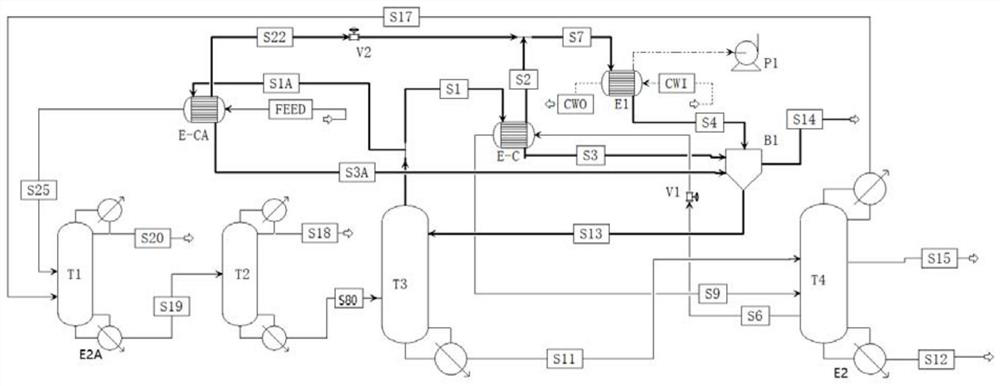

[0047] as Figure 3As shown, the condensing liquid product FEED from the oxalate hydrogenation reaction section has a temperature of 90 °C and enters the dehydration tower T1 after passing through the coupling heat exchanger E-CA, Dehydration tower T1 top pressure 0.6atm, dehydration tower T1 top extraction of water and methanol and other light components of the shunt strand S20, dehydration tower T1 bottom stream S19 into the deoxate tower T2, deoxate tower T2 top pressure 0.5atm, deoxate tower T2 top extraction mainly for oxalate and methyl glycolate flow strand S18, bottom of the tower extracted flow strand S80 into the debutanol tower T3, debutantol tower T3 top pressure 0.4atm, temperature 162 °C, debutantol tower T3 tower top of the binary alcohol vapor is divided into parallel S1 and S1A two parts, respectively through the coupling heat exchanger E-C and coupled heat exchanger E-CA , coupling heat exchanger E-C uncoated steam S2 and coupled heat exchanger E-CA uncoated steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com