Vacuum pipe and refrigerator

A technology of vacuum tubes and inner tubes, which is applied in the field of refrigeration and freezing devices, and can solve problems such as inability to satisfy users to adjust the position of the refrigerator, complex process, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, orientations or positional relationships indicated by "front", "rear", "upper", "lower", "left", "right", etc. are orientations based on the refrigerator 200 itself as a reference.

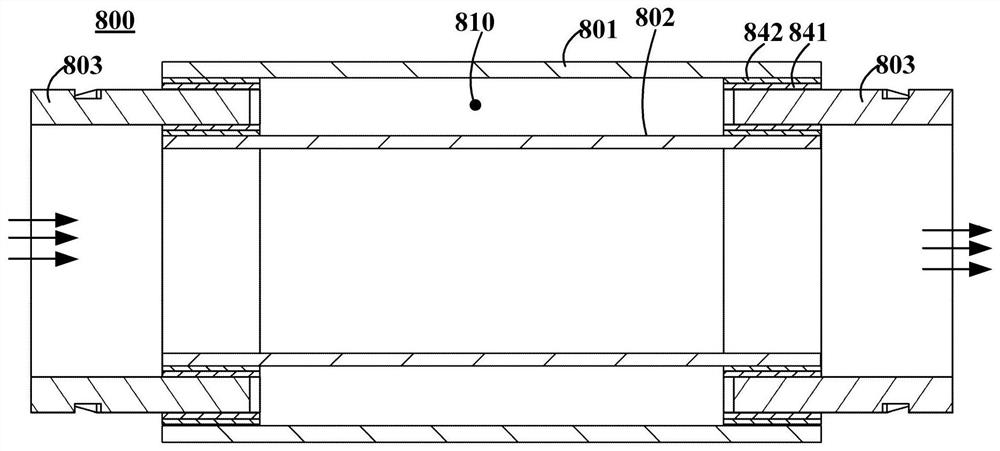

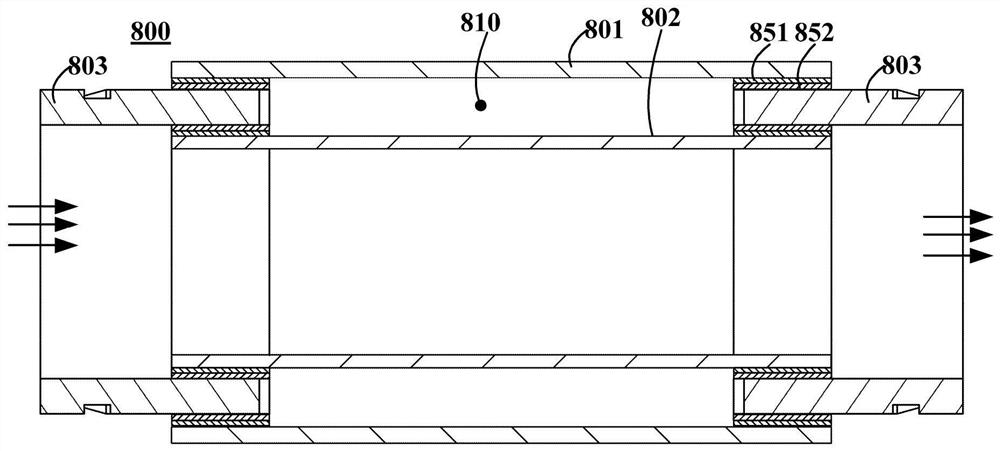

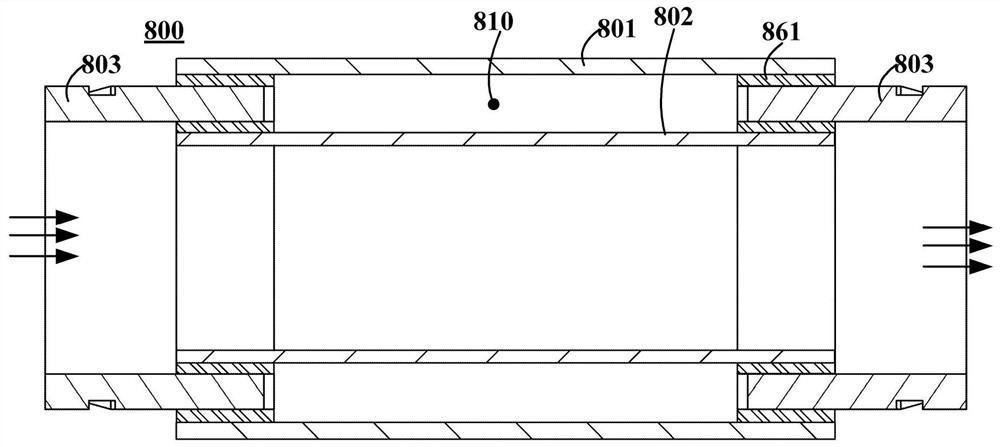

[0038] figure 1 is a schematic structural diagram of a vacuum tube 800 according to an embodiment of the present invention. figure 2 is a schematic structural diagram of a vacuum tube 800 according to another embodiment of the present invention. image 3 It is a structural schematic diagram of a vacuum tube 800 according to yet another embodiment of the present invention. The vacuum tube 800 of the present invention includes an outer tube 801, an inner tube 802, and an end sealing member 803, wherein the outer tube 801 is sleeved outside the inner tube 802 and is spaced apart from the inner tube 802; the end sealing member 803 is configured to sandwich A vacuum cavity 810 is defined between the outer tube 801 and the inner tube 802 to seal and fix the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com