In-service structure prestress detection method based on resistance strain effect

A technology of resistance strain and detection method, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of high cost, detection method not suitable for in-service structure, low signal-to-noise ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a method for detecting the prestress of an in-service structure based on the resistance strain effect.

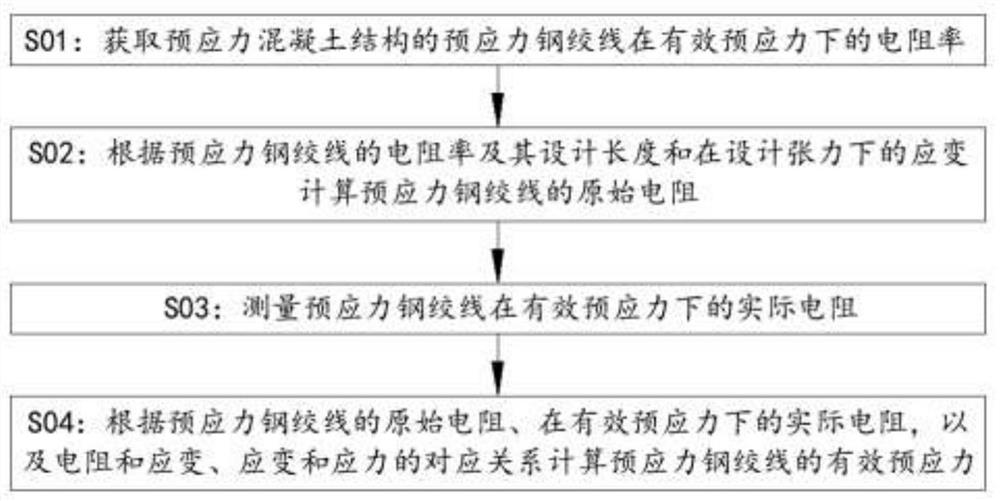

[0035] Such as figure 1 and figure 2 As shown, a prestress detection method for in-service structures based on the resistance strain effect includes the following steps:

[0036] S01: Obtain the resistivity of the prestressed steel strand of the prestressed concrete structure under effective prestress;

[0037] S02: Calculate the original resistance of the prestressed steel strand according to the resistivity of the prestressed steel strand, its design length and the strain under the design tension;

[0038] S03: Measure the actual resistance of the prestressed steel strand under effective prestress;

[0039] S04: Calculate the effective prestress of the prestressed steel strand according to the original resistance of the prestressed steel strand, the actual resistance under the effective prestress, and the corresponding relationship bet...

Embodiment 2

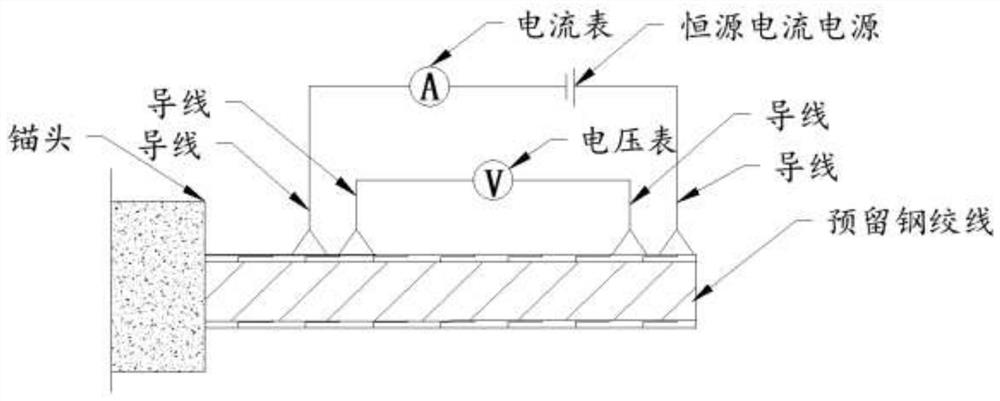

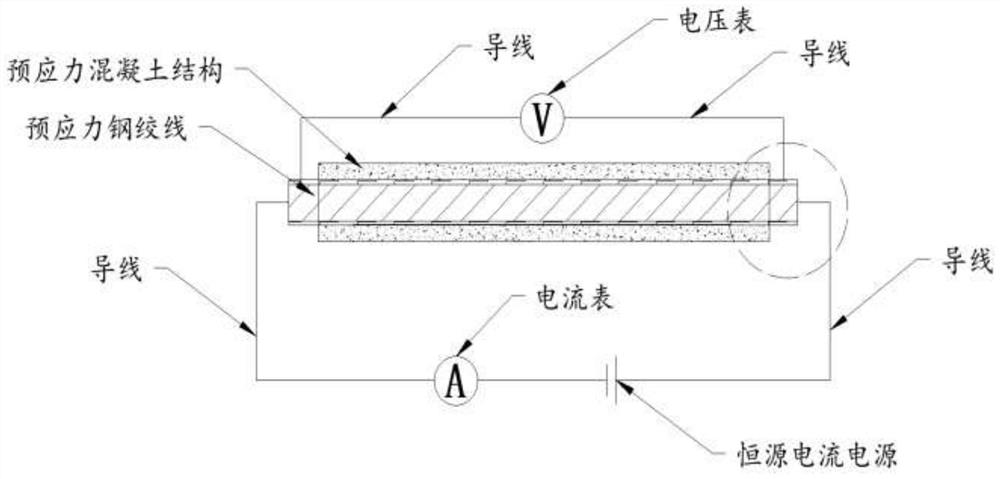

[0061] On the basis of the first embodiment, this embodiment discloses a resistance testing device that implements the four-terminal method for measuring resistance.

[0062] The resistance testing device in this embodiment is used to implement the four-terminal method for measuring resistance. combine Figure 4 As shown, the resistance testing device includes a constant source current power supply and an ammeter which are arranged in series with each other and form a current path in series with the steel strand under test during measurement, and are connected with the steel strand under test during measurement and are connected to the constant source current power supply and the The ammeter is arranged in parallel with the voltmeter. Specifically, the terminal of the voltmeter on the steel strand to be tested should be inside the terminal of the ammeter. combine figure 2 and image 3 As shown, the constant source current power supply, ammeter and voltmeter are all connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com