An inductive strain sensor

A stress sensor and inductive technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of complex optical path processing equipment of sensors, no need for static pressure measurement, sensitive measurement temperature, etc., and achieve simple structure, easy maintenance and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

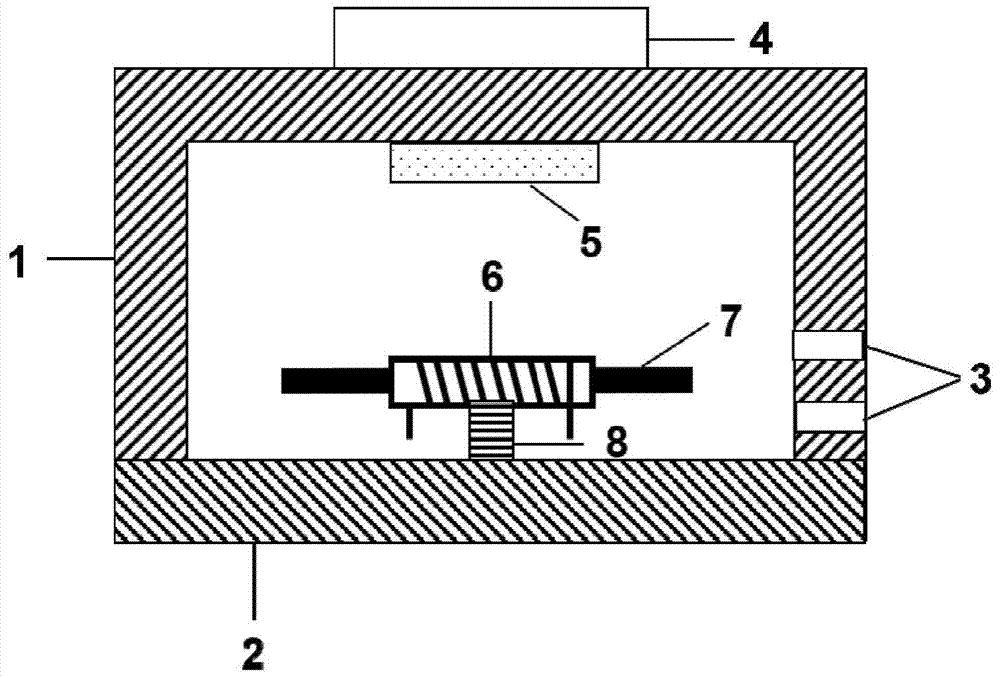

[0030] In this embodiment, the structure of the inductive stress sensor is as follows figure 1 As shown, it includes a supporting shell, a stress receiving body 4 connected to the outside of the supporting shell, and a magnet 5 and an inductance coil inside the supporting shell.

[0031] The supporting shell is composed of a base 2 and a shell 1 .

[0032] The inductance coil is composed of a magnetic core 7 and an air-core coil, and the magnetic core 7 passes through the inside of the air-core coil. The hollow coil is formed by winding the enameled wire around the periphery of the hollow cylinder 6 . The inductance coil is fixed on the base 2 through the fixing column 8, and the inductance coil is placed horizontally, that is, the length direction of the coil is parallel to the horizontal plane.

[0033] In the supporting shell, the part connected with the stress receiving body 4 is a pressure receiving part, the stress receiving body 4 is located on the outer wall surface ...

Embodiment 2

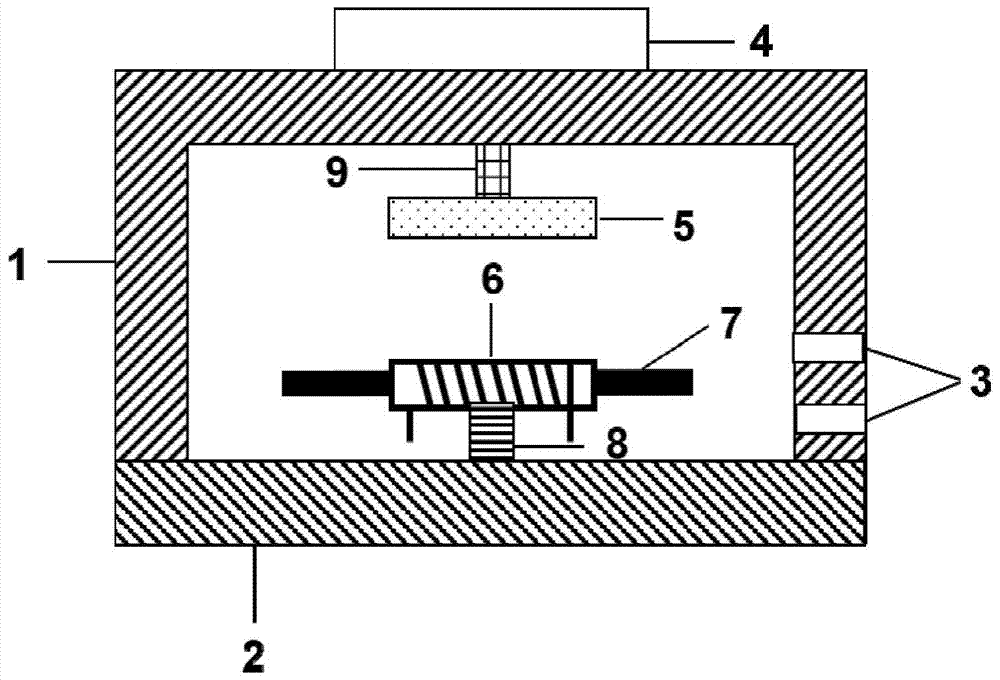

[0039] In this embodiment, the structure of the inductive stress sensor is as follows figure 2 As shown, the structure is basically the same as the structure of the inductive stress sensor in Embodiment 1, except that the magnet 5 is connected to the pressure-bearing part through the fixed column 9; the fixed column 9 is fixedly connected to the inner wall of the pressure-bearing part, and the magnet and the pressure-bearing part The fixed column 9 is fixedly connected, and the magnet is located directly below the position of the stress receiving body.

Embodiment 3

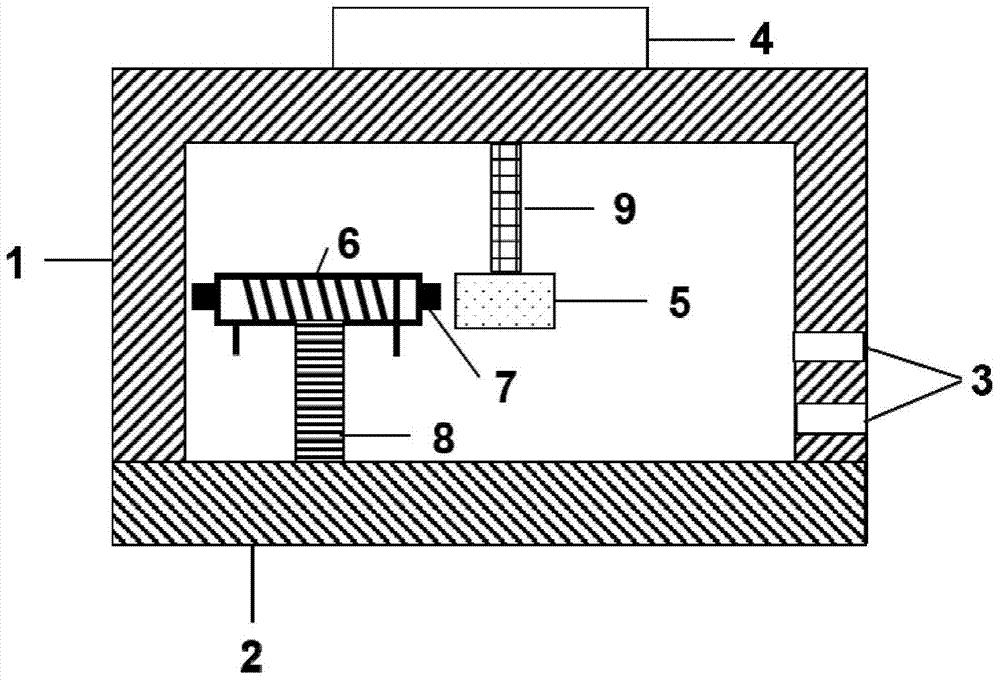

[0041] In this embodiment, the structure of the inductive stress sensor is as follows image 3 As shown, the structure is basically the same as that of the inductive stress sensor in Embodiment 2, except that the magnets 5 are distributed on the axis of the coil along the length direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com