Novel portable pulverized coal pipeline sampling device

A pulverized coal pipeline and sampling device technology, applied in the direction of sampling devices, etc., can solve problems such as gas leakage, pipeline complexity, and unrecorded existence of sealing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

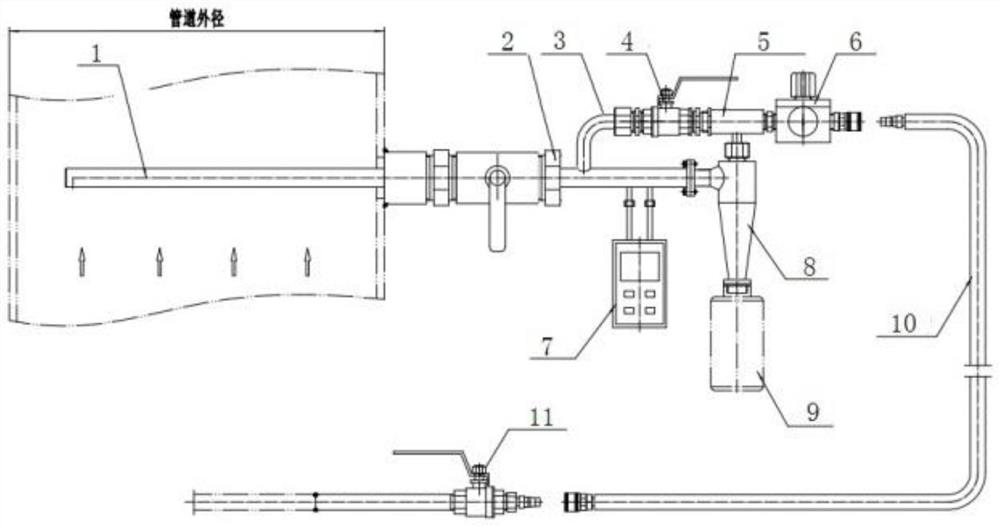

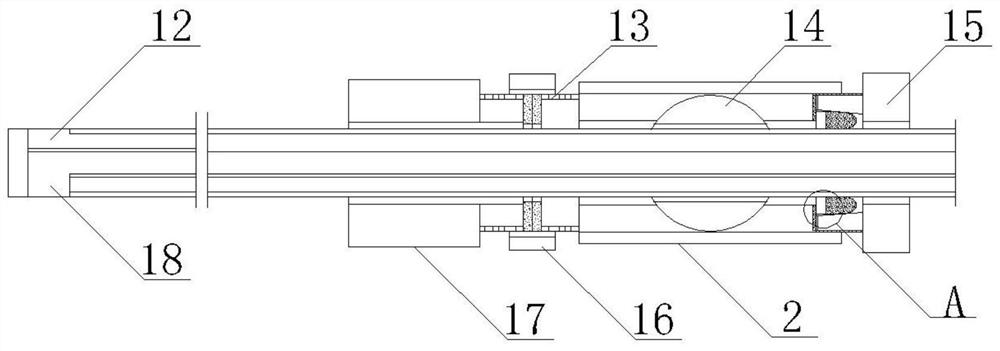

[0028] Such as figure 1 and figure 2As shown, the novel portable pulverized coal pipeline sampling device of this embodiment includes a pulverized coal pipeline, and the surface of the pulverized coal pipeline is installed with a fixed pipe head 17 through the surface. A socket pipe 2 is detachably installed on the pipe head 17, the two are connected to each other, and the pipe diameter and length of the socket pipe 2 are relatively large, and a sampling gun 1 is installed in the socket pipe 2 through a switch sealing mechanism, and the sampling gun One end of 1 extends to the pulverized coal pipeline, and the sampling gun 1 is actually socketed with the socket pipe 2. During operation, the sampling gun 1 is inserted into the pulverized coal pipeline through the socket pipe 2 and the fixed connection pipe head 17, and the sampling gun The other end of 1 extends out of the socket pipe 2, that is, the existing part is outside the socket pipe 2, and the interior of the sampling...

Embodiment 2

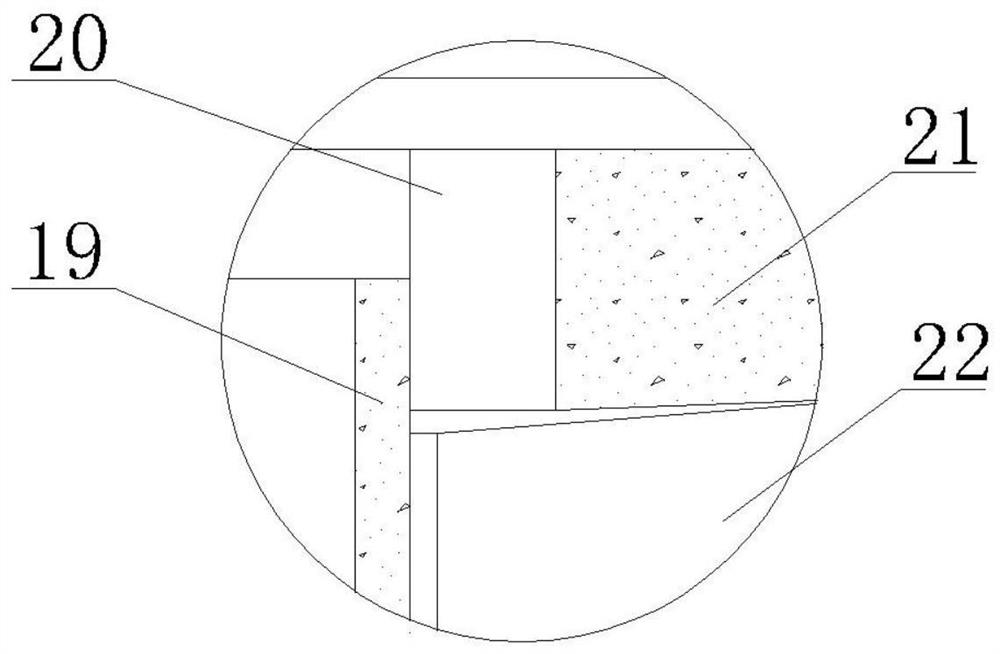

[0037] The structure of the new portable pulverized coal pipeline sampling device in this embodiment is basically the same as that of the new portable pulverized coal pipeline sampling device in Embodiment 1, the difference is that a sealing member is installed between the sealing plug 15 and the sampling gun 1 The sealing part comprises snap ring 20, cushion block 21 and curved surface block 22, and curved surface block 22 is installed on the end surface of sealing plug 15, and the outer surface of curved surface block 22 is connected with socket pipe 2 by screw thread, and the inside of curved surface block 22 A slope is provided, and the snap ring 20 is installed on the surface of the sampling gun 1 adjacent to the sealing plug 15. The snap ring 20 is used in conjunction with the curved block 22, and the spacer 21 is installed in the gap between the snap ring 20 and the curved block 22. The spacer 21 Ring-shaped rubber block structure (see image 3 ). The snap ring 20 actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com