Cold-pressed terminal

A technology of cold-pressed terminals, front and rear ends, applied to electrical components, devices for joining/disconnecting parts, coupling devices, etc., which can solve problems such as non-reusable, wire falling off, and low wiring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

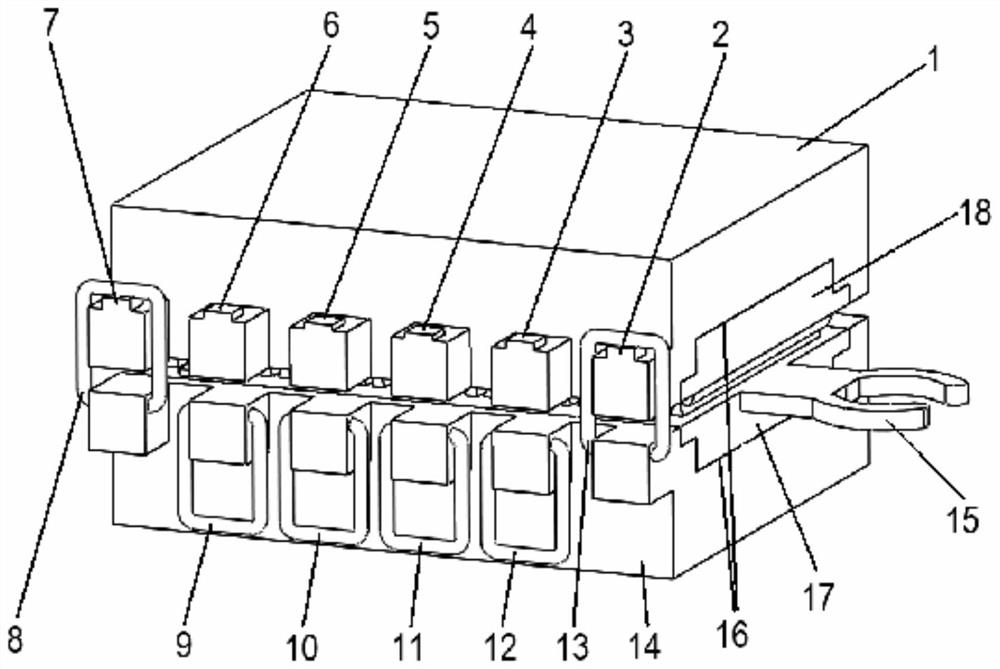

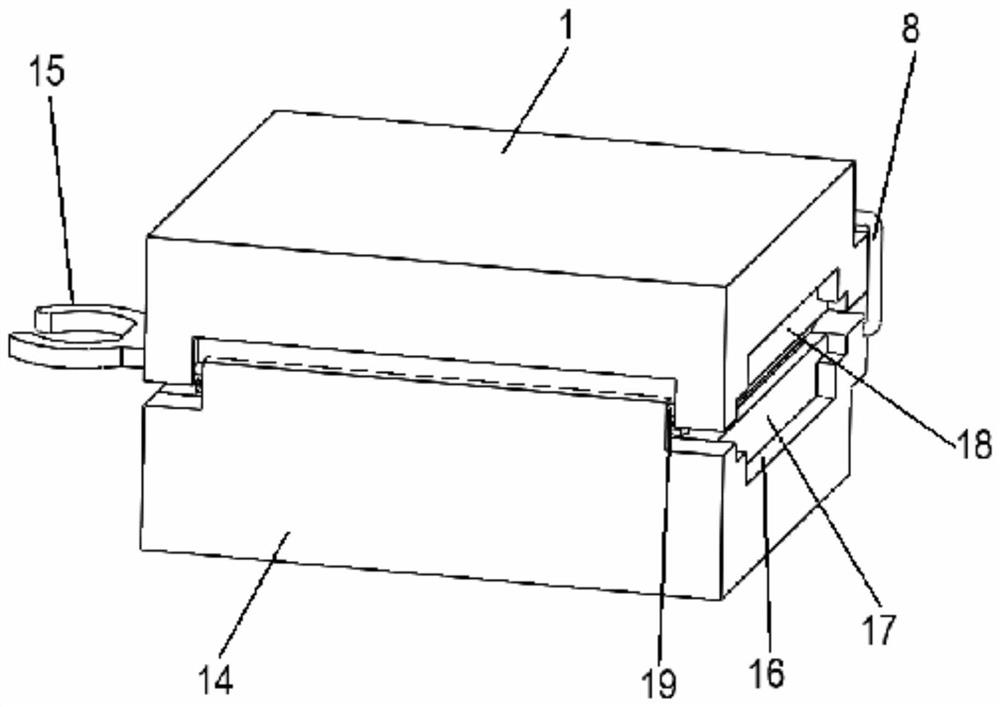

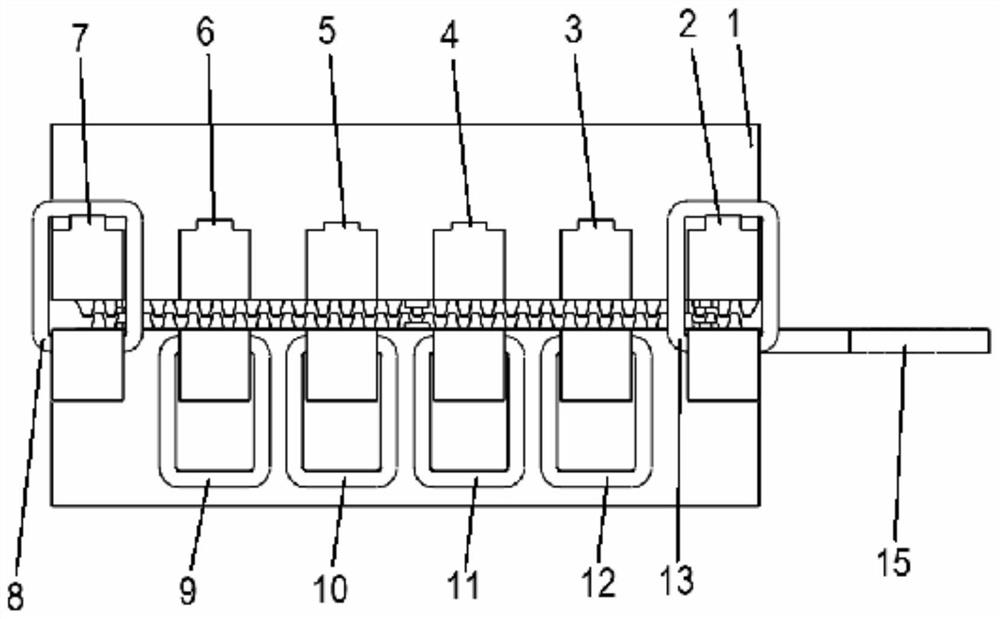

[0022] Such as Figure 1 to Figure 4 As shown, a cold-press terminal of the present invention includes an upper jaw 1 and a lower jaw 14. The front ends of the upper jaw 1 and the lower jaw 14 are provided with 3 buckle connections, and the rear ends of the upper jaw 1 and the lower jaw 14 are connected by a living hinge 19. Rotate freely within 0~180 degrees around the living hinge 19, the upper jaw 1 and the lower jaw 14 are provided with concave grooves 16, and the concave grooves 16 are respectively equipped with upper teeth 18 and lower teeth 17, upper teeth 18, lower teeth 17 and concave teeth The slots 16 are fixedly connected by fastening screws 20 , and the right end of the mandibular teeth 17 is fixedly provided with an electrical connector 15 .

[0023] Further, the front end of the upper jaw 1 is symmetrically fixed with three pairs of bosses sequentially from left to right, that is, the first boss 2 and the sixth boss 7, the second boss 3 and the fifth boss 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com