Preparation method of graphene oxide water treatment membrane capable of generating surface nanobubbles in situ

A technology of nano-bubbles and water treatment membranes, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, membrane technology, etc., can solve the problems of large flow resistance and difficulty in achieving ideal permeability of the membrane, and achieve the improvement of permeability , Reduce fluid flow resistance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, prepare the graphene oxide water treatment membrane that can generate surface nano bubbles in situ, the steps are as follows:

[0023] Step 1, the preparation of graphene oxide-polyfluoroaniline composite:

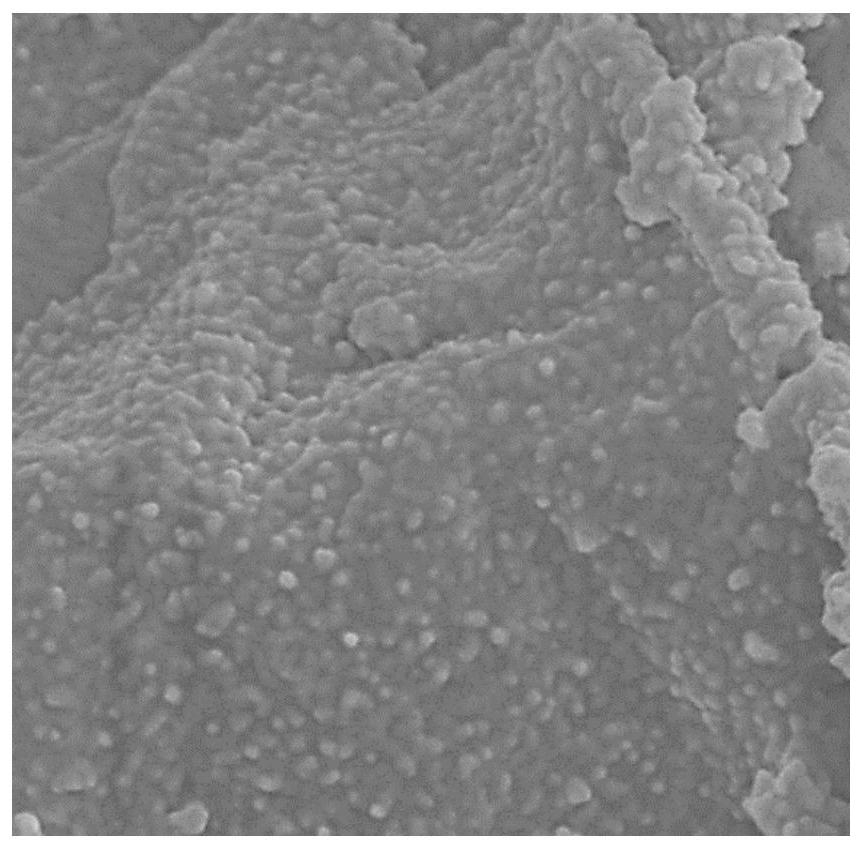

[0024] 21 mg of graphene oxide was added to a mixed solution of 20 mL of isopropanol and 100 mL of 1M hydrochloric acid, and ultrasonicated for 60 min to obtain a good dispersion. Then 11.25 mM ammonium persulfate was added to the above dispersion to form an aqueous phase. Meanwhile, 7.5 mM 2-fluoroaniline was dissolved in 100 mL of dichloromethane to form an oil phase. Then the water phase was carefully poured into the oil phase, and the reaction was carried out at 0°C for 72 hours. The product was filtered, washed several times with deionized water and ethanol, and dried in vacuum at 60°C to obtain a graphene oxide-polyfluoroaniline composite. The electron microscope image of the complex is shown in image 3 shown.

[0025] Step 2. Preparation of...

Embodiment 2

[0028] Embodiment 2, preparation of geometry-chemical double heterogeneous graphene oxide water treatment membrane, its preparation process is basically the same as embodiment 1, the only difference is: in step 1, the concentration of ammonium persulfate is changed from 11.25mM to 1.5mM, 2 -The concentration of fluoroaniline was changed from 7.5mM to 1.0mM, and the geometric-chemical double heterogeneous graphene oxide water treatment membrane was finally prepared.

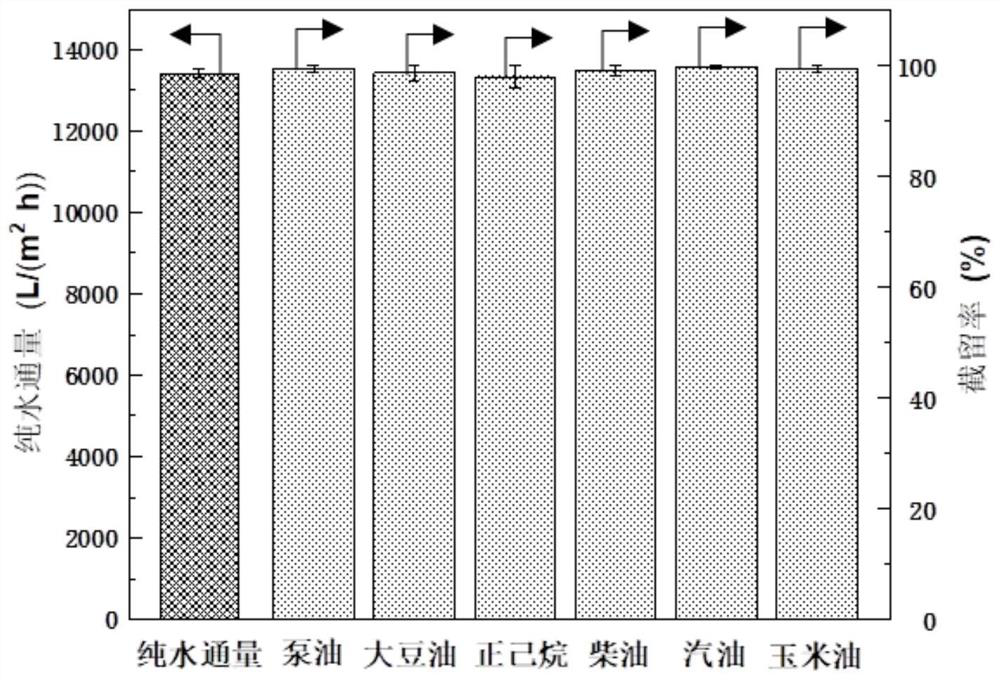

[0029] The pure water flux of the geometric-chemical double heterogeneous graphene oxide water treatment membrane made in embodiment 2 is 14.24±4.3L / (m 2 h), the rejection rate of corn oil / water emulsion (mass fraction of corn oil is 0.1%) is 99.1±0.9%.

Embodiment 3

[0030]Embodiment 3, preparation of geometry-chemical double heterogeneous graphene oxide water treatment membrane, its preparation process is basically the same as embodiment 1, the only difference is: in step 1, the concentration of ammonium persulfate is changed from 11.25mM to 3.75mM, 2 -The concentration of fluoroaniline was changed from 7.5mM to 2.5mM, and finally a geometric-chemical double heterogeneous graphene oxide water treatment membrane was prepared.

[0031] The pure water flux of the geometric-chemical double heterogeneous graphene oxide water treatment membrane prepared in Example 3 is 938.81±33L / (m 2 h), the rejection rate of corn oil / water emulsion (mass fraction of corn oil is 0.1%) is 98.1±1.9%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap