Manufacturing method of nanometer protective coating on surface of metal plate

A metal sheet and protective coating technology, applied in spray devices, spray booths, etc., can solve the problems of inability to automatically turn over, cumbersome process, uneven atomization of paint particles, etc., to protect health, ensure uniformity, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

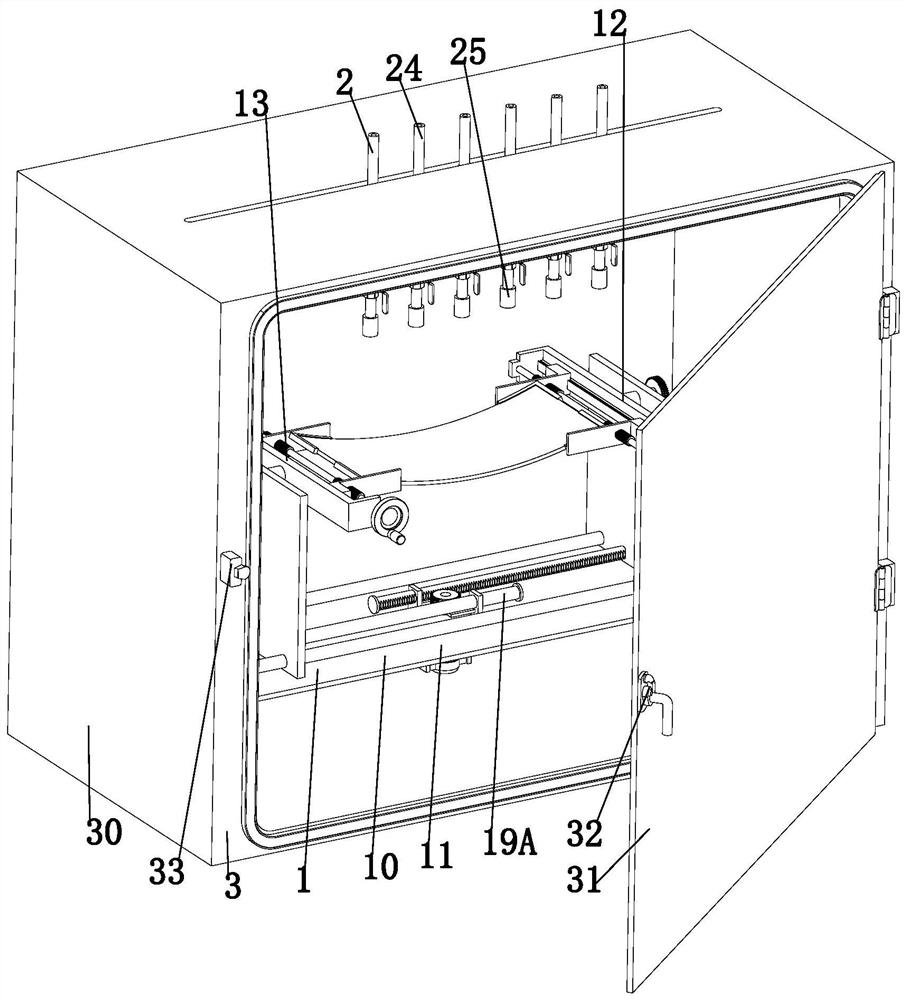

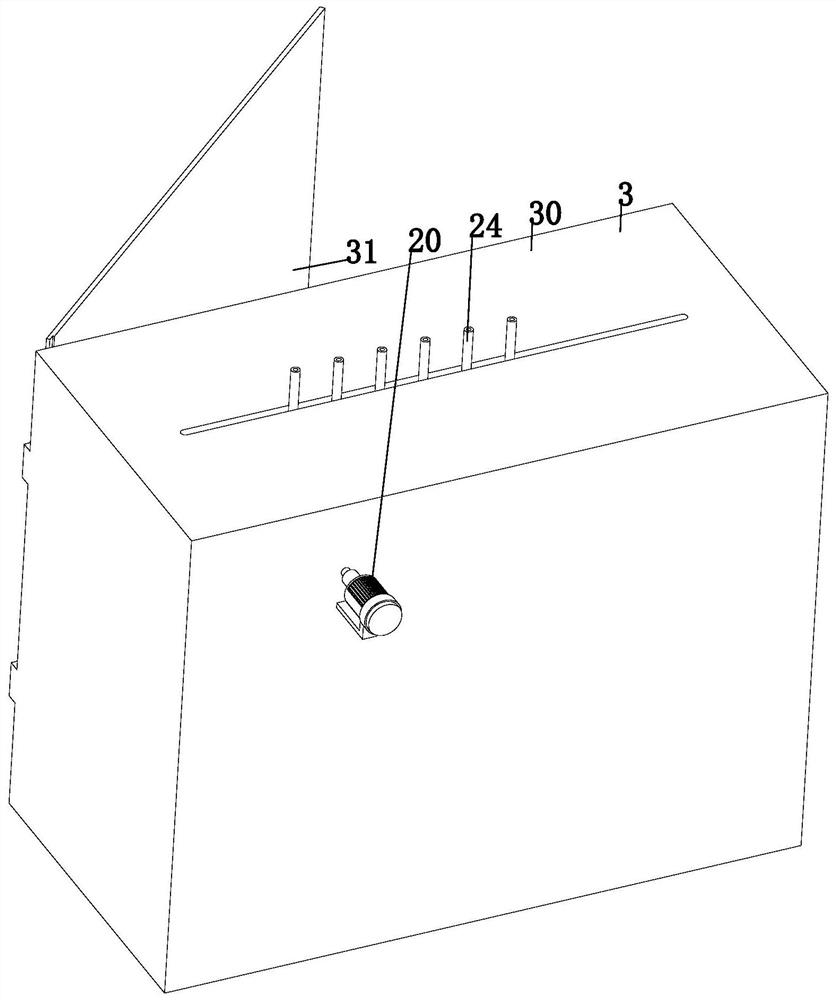

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

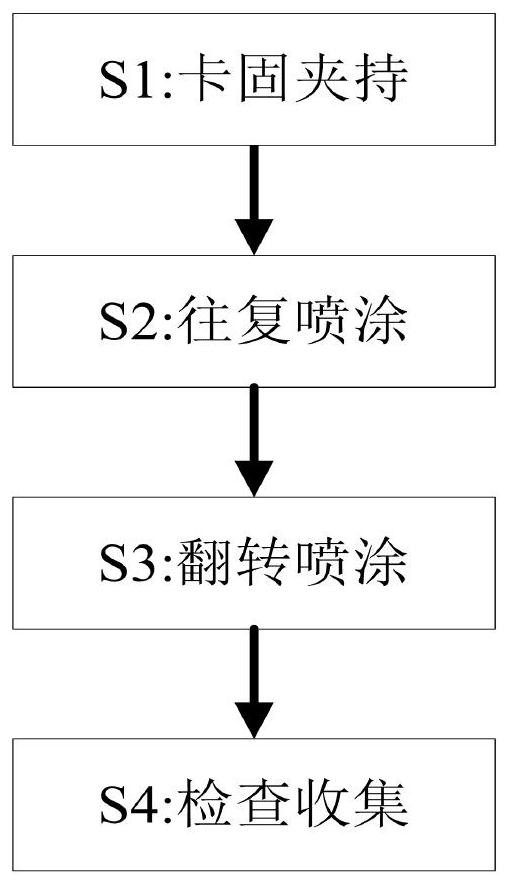

[0036] Such as Figure 1 to Figure 8 Shown, a kind of metal plate surface nano-protective coating manufacturing method, it has used a kind of metal plate surface nano-protective coating spraying equipment, this spraying equipment comprises clamping mechanism 1, spraying mechanism 2 and box body mechanism 3, adopts above-mentioned The specific method for the spraying equipment to carry out nano-protective spraying treatment on the surface of the metal plate is as follows:

[0037] S1. Clamping and clamping: By adjusting the distance of the clamping mechanism 1, it can meet the clamping and fixing of metal plates of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com