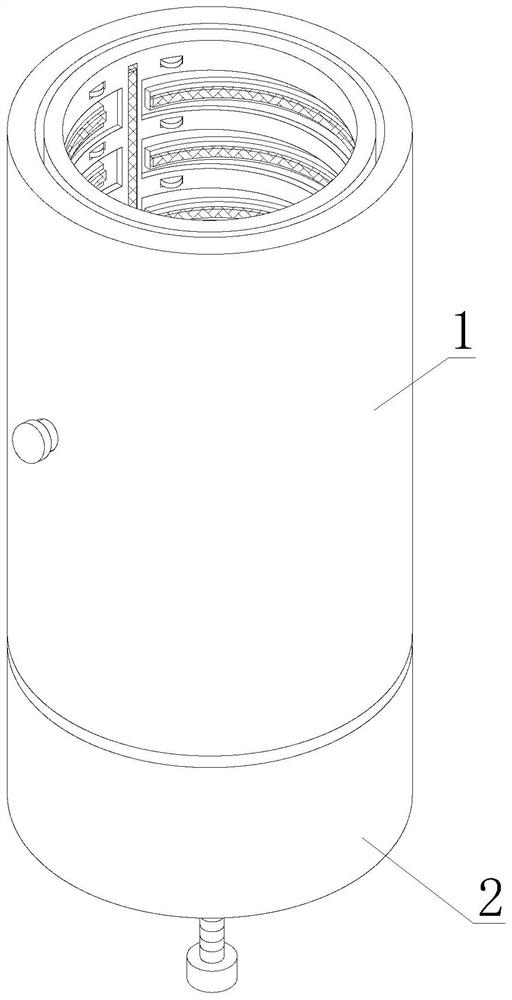

Scraping type recovery device for fused salt on anode surfaces of waste electrolytic graphite products, and implementation method thereof

A technology of electrolytic graphite and recovery device, applied in the field of molten salt, can solve problems such as unfavorable scraping work of graphite products, no lifting and scraping of graphite products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

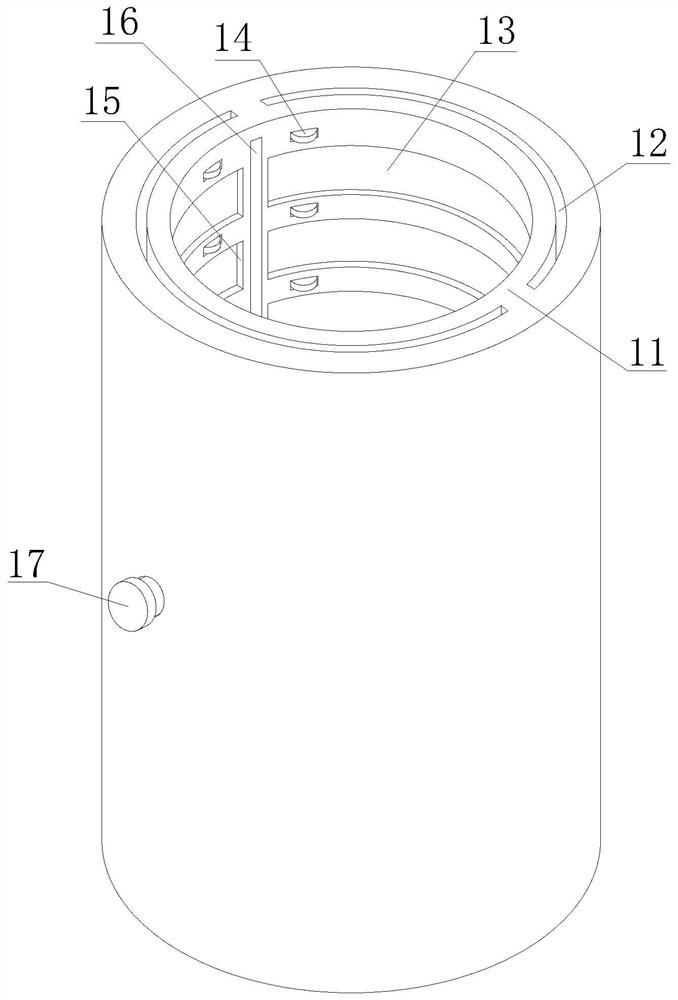

[0041] In order to further and better explain the above examples, the present invention also provides an embodiment, a method for implementing a scraping-type waste electrolytic graphite product anode surface molten salt recovery device, including the following steps:

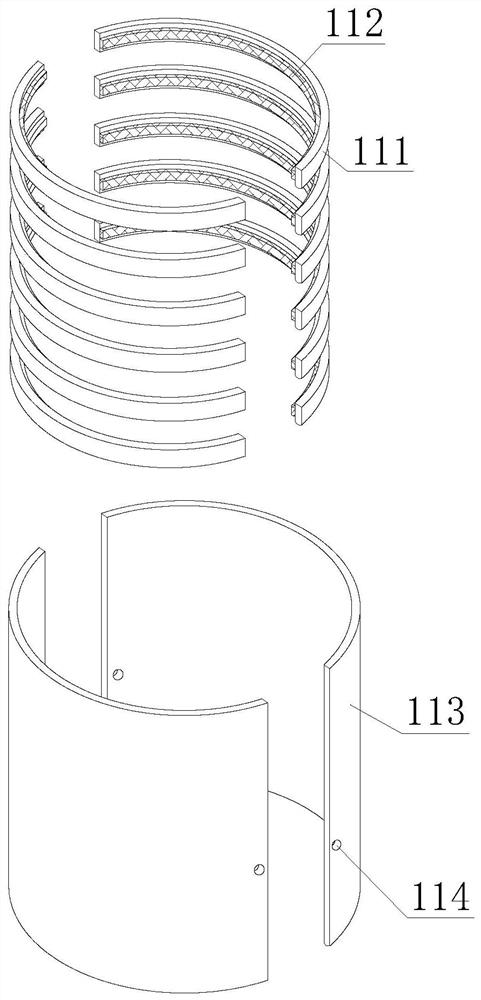

[0042] Step 1: fitting the columnar graphite product into the hollow circular frame 11, one end of the second return spring 145 is fixedly connected to the inner wall of the strip groove 144, and the other end is fixedly connected to the side of the shaft column 142, and the clamping wheel 143 can be squeezed, Thereby extruding the second back-moving spring 145, so that the position of the clamping wheel 143 is inside the hollow circular frame 11 at this time, which facilitates the fitting of columnar graphite products;

[0043] Step 2: Since the adjustment column 22 runs through the bottom frame 21 and the diameter gradient column 23 is movably connected inside the fixed block 24, twisting the adjustment column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com