Workpiece surface leveling device and method

A technology of leveling device and workpiece surface, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of difficulty in measuring the hardness and hardness of the surface to be measured, and improve the measurement efficiency and measurement accuracy. , Save adjustment time, strong practicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

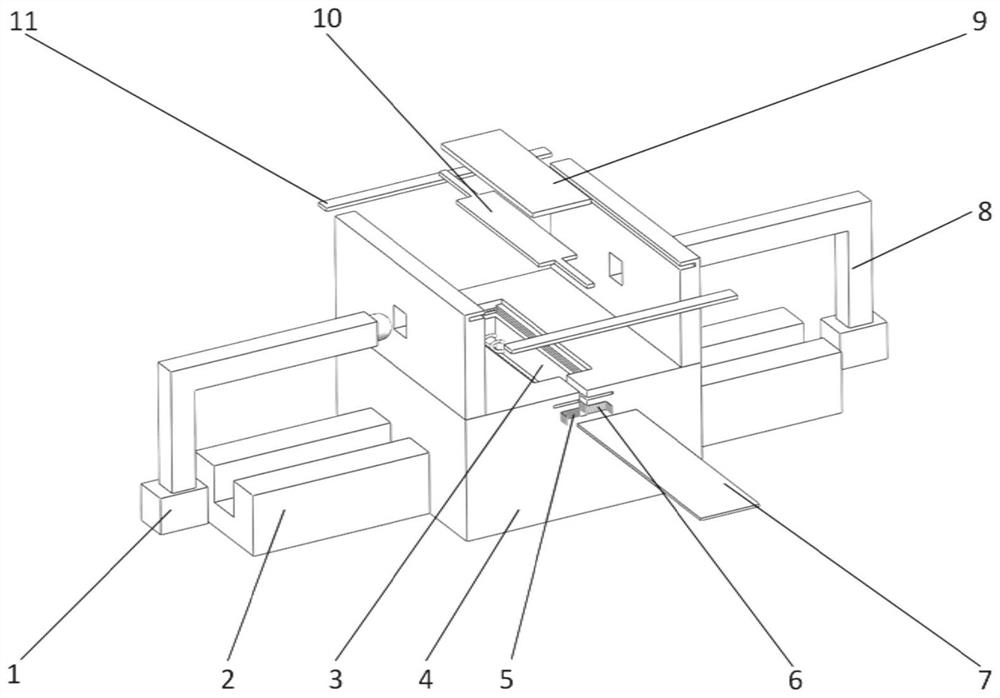

[0028] Such as figure 1 As shown, the embodiment of the present invention provides an overall structural diagram of a workpiece surface leveling device for a hardness tester. The structure mainly includes the workpiece clamping system, workpiece leveling system, workpiece positioning system and workbench part.

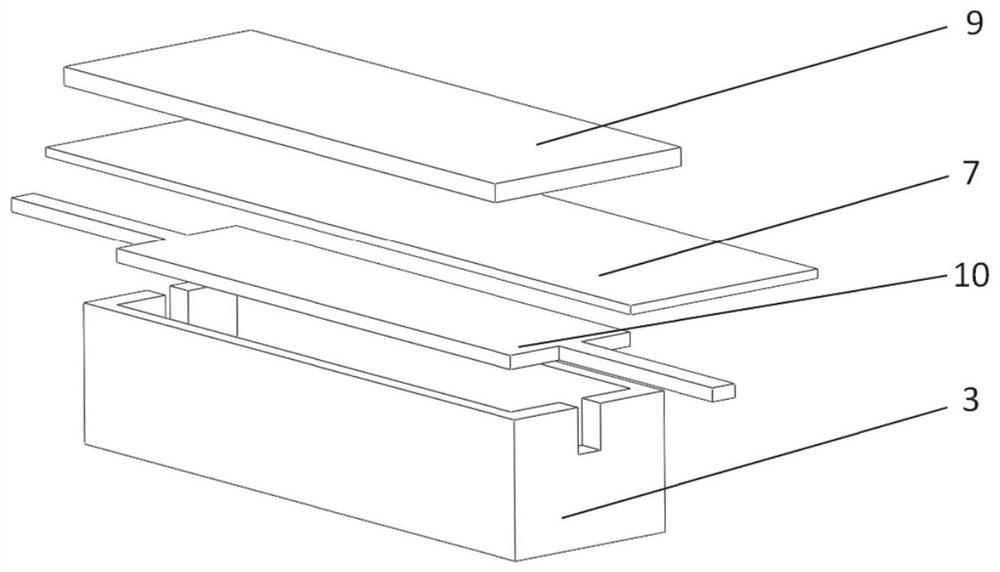

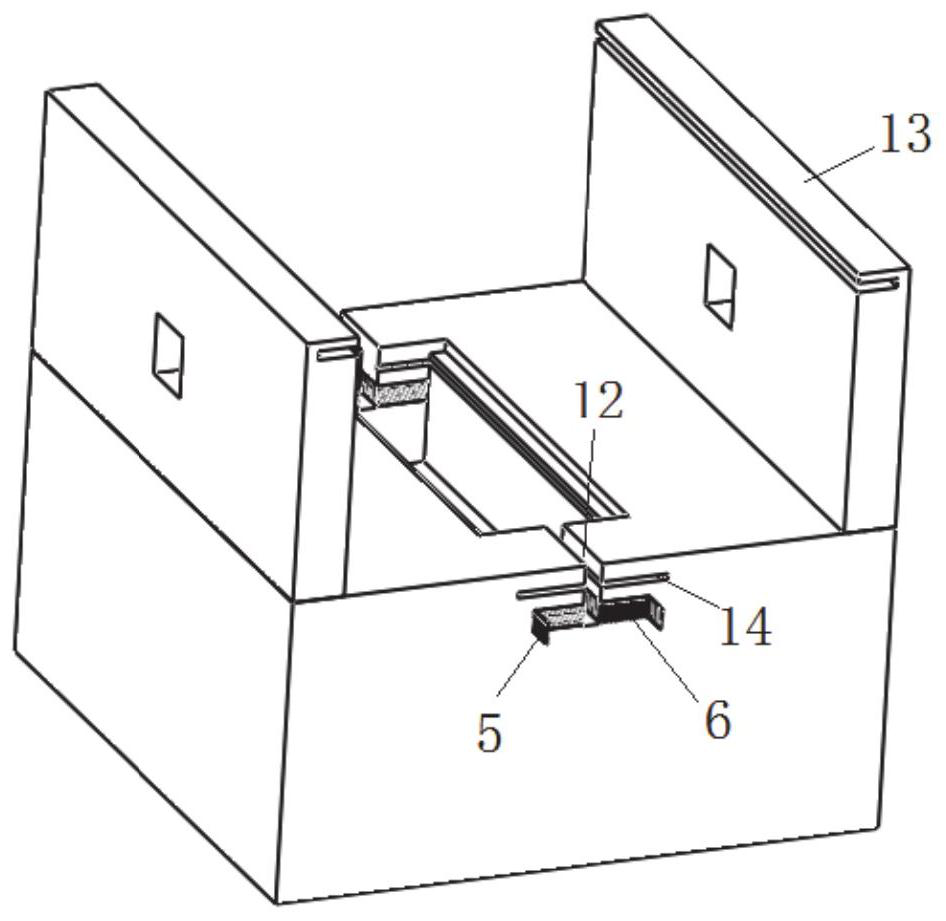

[0029] Specifically, refer to Figure 1-Figure 3 As shown, in the embodiment of the present invention, the interior of the workbench 4 is provided with an accommodation space for placing the spring box 3. The top of the spring box 3 is open, and the workbench 4 is used to place the workpiece under test. Extend downwards on the surface and form a vertical groove 12, this vertical groove 12 communicates with the accommodating space that places spring case 3, is provided with several vertically placed springs in spring case 3, and the top of these springs A spring case cover 10 is connected on the top, and the spring case cover 10 can slide in the vertical chute 12 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com