Cleaning robot device

A high-pressure cleaning machine and robot body technology, applied in manipulators, manufacturing tools, etc., can solve the problems of operator discomfort, low efficiency, poor cleaning effect, etc., and achieve the effect of good application prospect, convenient use and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

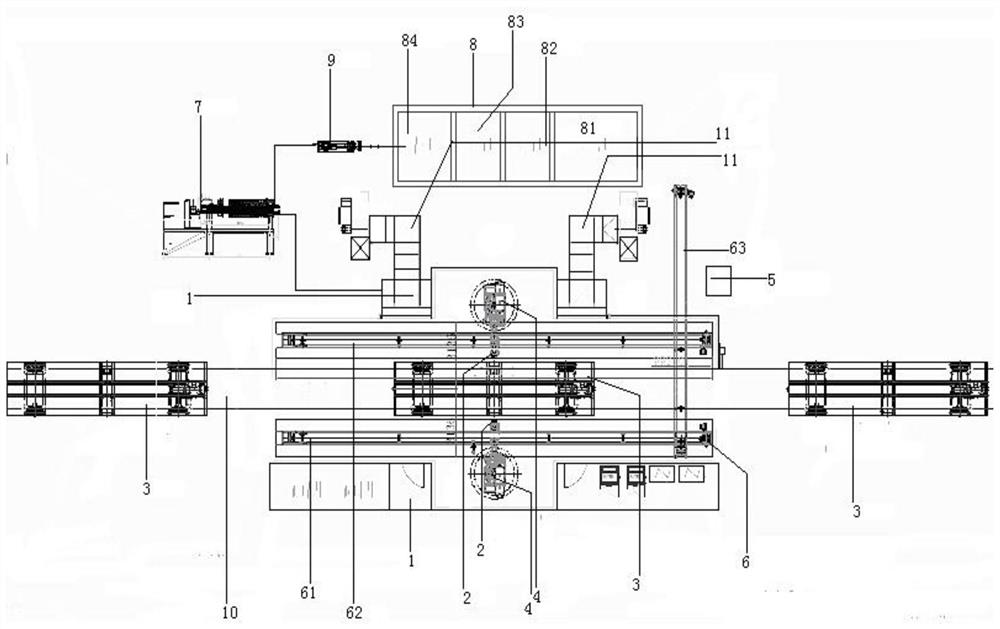

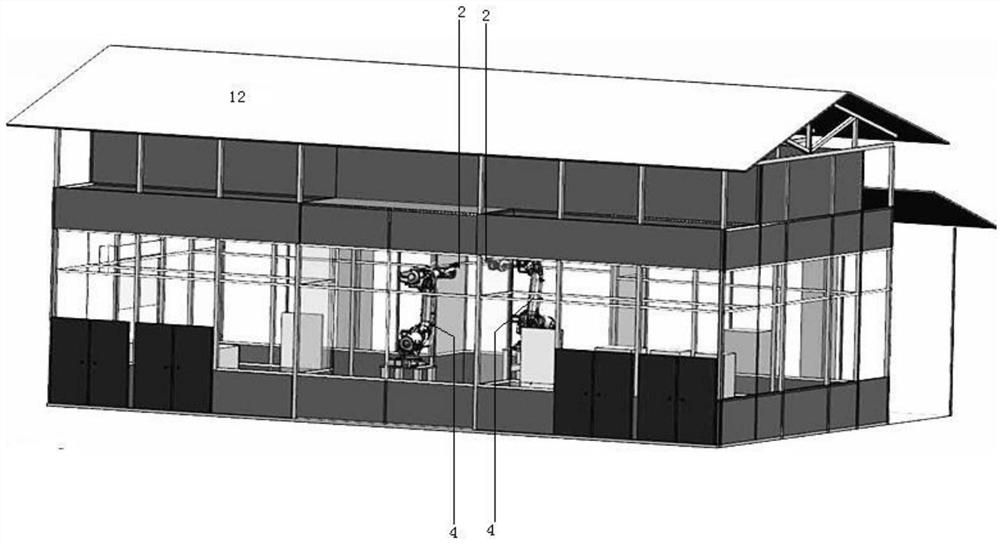

[0014] figure 1 , 2 As shown in , a cleaning robot device includes a high-pressure cleaning machine 1, a high-pressure water gun 2, an intelligent rail flat car 3, a robot body 4 with a robot arm that can move in multiple directions, a PLC 5, a scraper machine 6, a water filtration device 7, Settling tank 8, water pump 9, settling tank 8 is located outside the cleaning workshop, the height of the upper end of the settling tank 8 is lower than the height of the outdoor ground, the end of the workshop drainage ditch is located at the water inlet end of the settling tank 8 and is higher than the height of the settling tank 8, the inlet of the water pump 9 The water pipe and the 8 outlet pipes of the sedimentation tank are connected through pipelines, the water outlet end of the water pump 9 is connected with the water inlet end of the water filter device 7 through pipelines, and the water outlet end of the water filter device 7 and the water inlet ends of the two sets of high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com