Sheet feeding apparatus and image forming apparatus

A sheet and feeding technology, applied in the direction of equipment, object supply, transportation and packaging of the electrical recording process using charge graphics, can solve the problems of setting characteristics and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

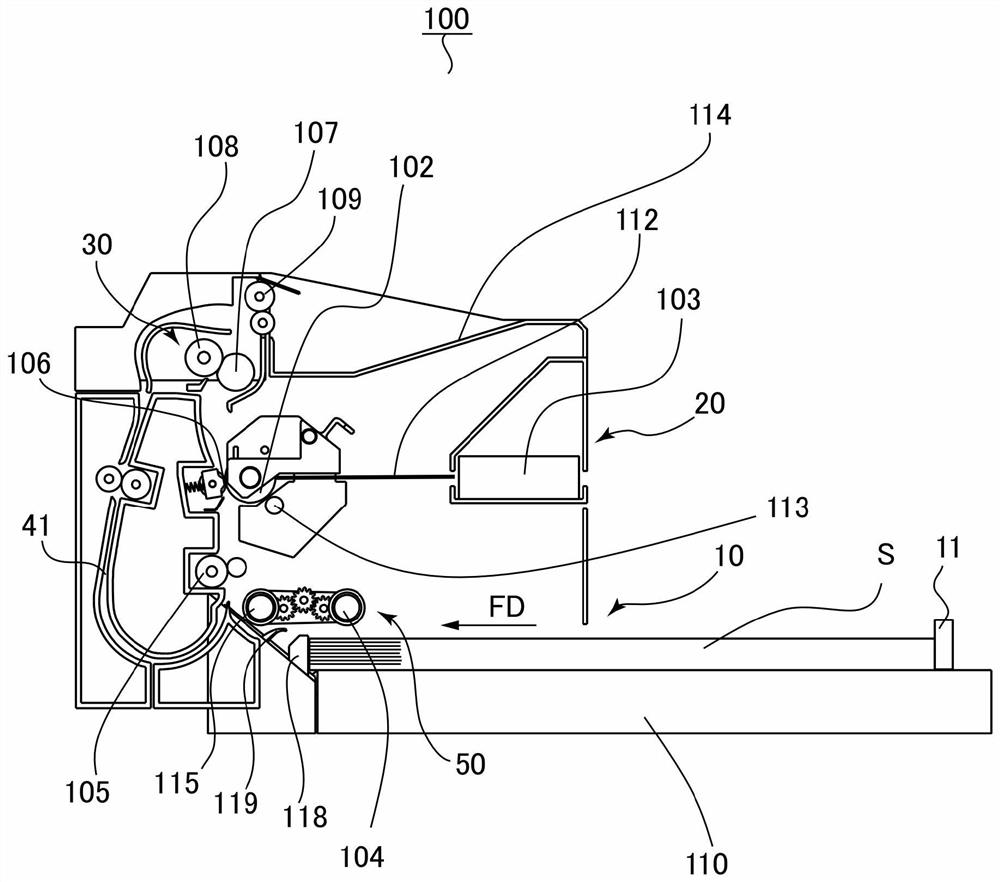

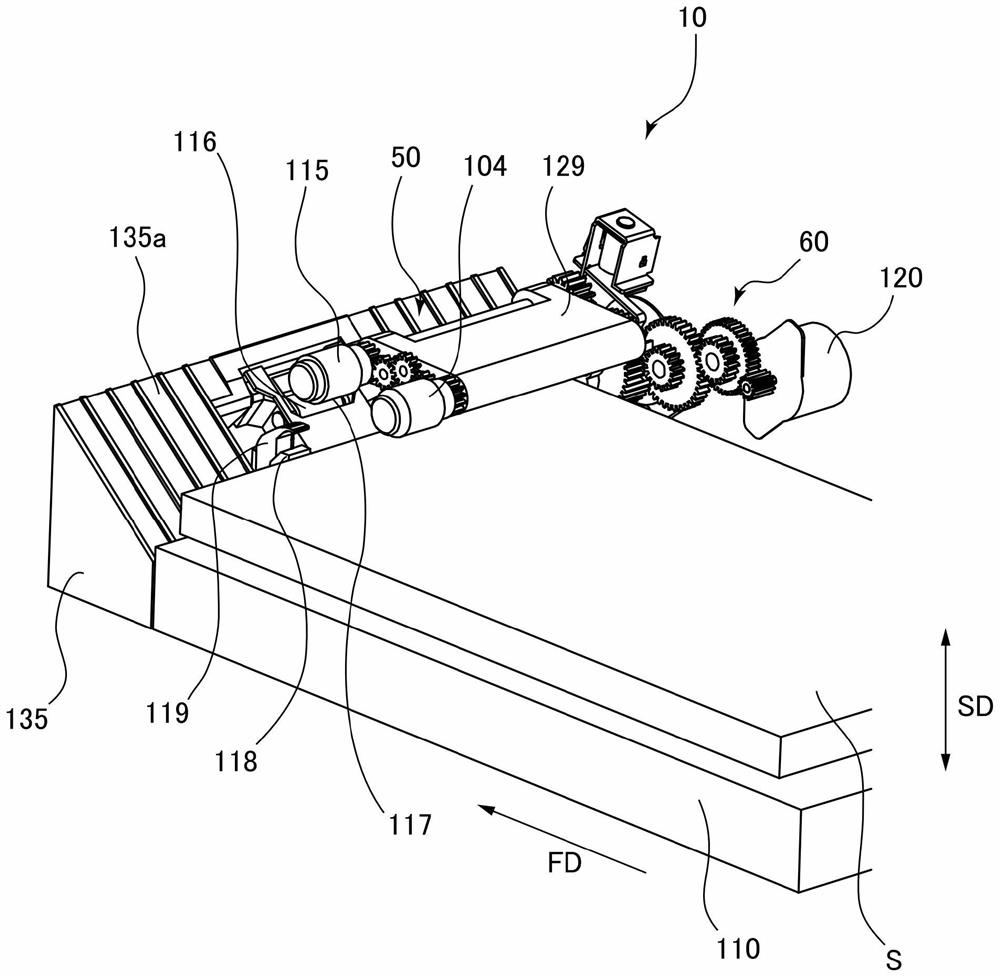

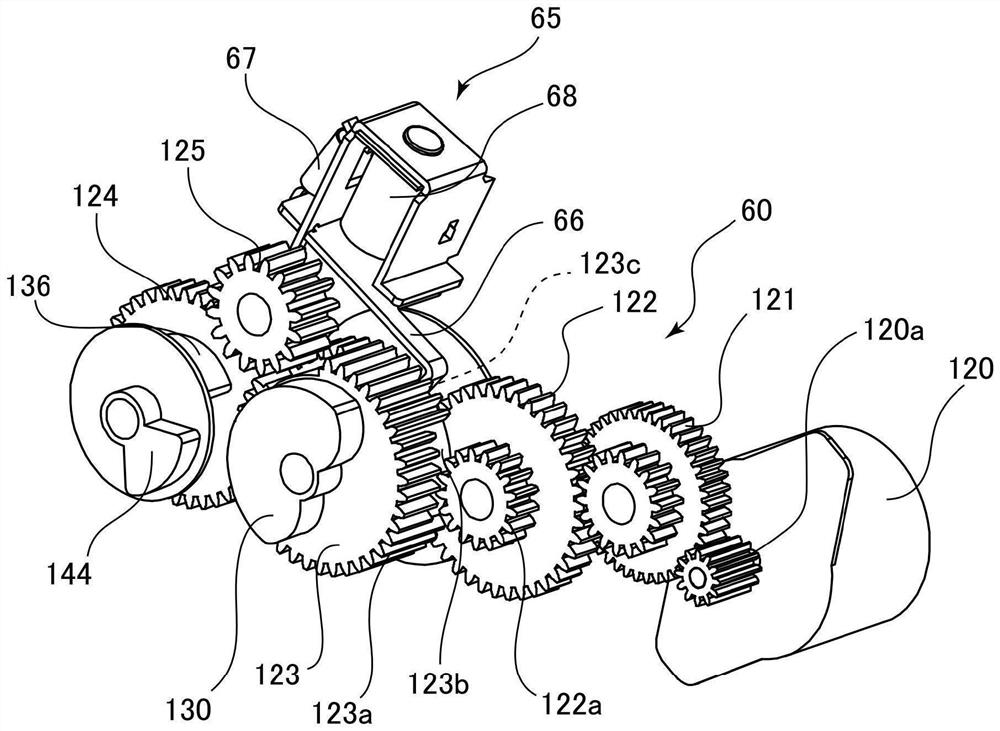

[0032] Now, a first embodiment of the present invention will be described. The printer 100 serving as the image forming apparatus according to the first embodiment is a laser beam printer employing an electrophotographic system. Such as figure 1 As shown, the printer 100 includes: a sheet feeding device 10 provided at a lower portion of the printer 100 , an image forming unit 20 that forms an image on a sheet S fed by the sheet feeding device 10 , a fixing unit 30 , and a sheet Material discharge roller pair 109.

[0033] In a state where an imaging command is output to the printer 100 , imaging processing by the imaging unit 20 starts based on image information input from an external computer or the like connected to the printer 100 . The image forming unit 20 includes a photosensitive drum 102 serving as an image bearing member, a developing roller 113 , a laser scanner 103 , and a transfer roller 106 . The laser scanner 103 irradiates laser light 112 toward the photosens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com