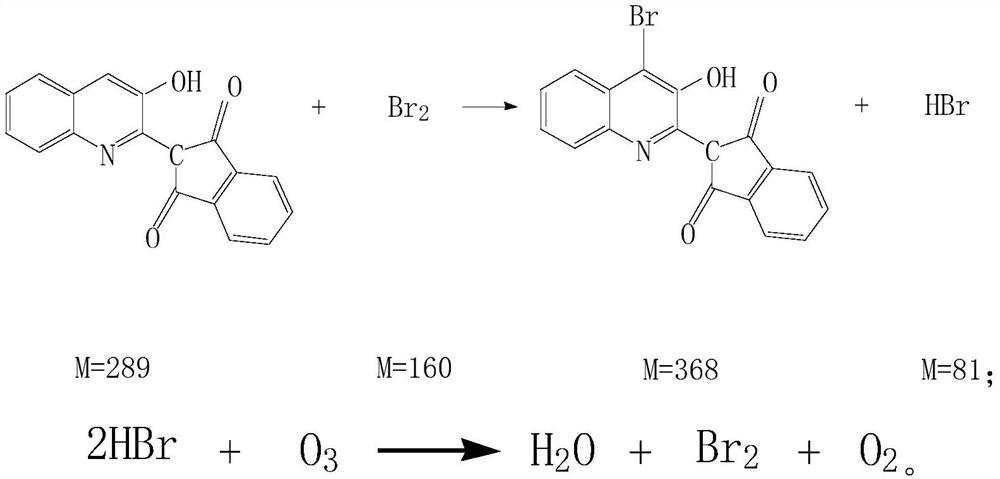

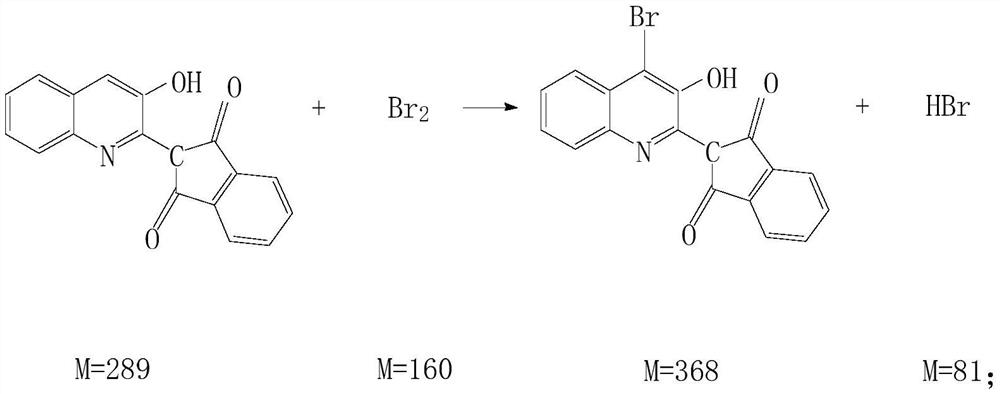

High-safety disperse yellow 64 synthesis process

A technology with high safety and synthesis process, applied in the direction of organic dyes, organic chemistry, quinoline phthalone dyes, etc., can solve problems such as safety hazards, and achieve the effect of safety in production process, avoidance of safety hazards and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 200 g (2 mol) of 98% sulfuric acid in a 500 ml four-neck flask, drop in Disperse Yellow 54 in a stirred state to be 50 g (0.173 mol), stir and heat up to 30-35° C.; add 40.0 g (0.494 mol) of hydrobromic acid dropwise, A total of 24 g (0.50 mol) of ozone was passed through for 1 hour, and the temperature was kept at 35-40°C for 1-2 hours. Then the temperature is raised to 50°C, and the reaction is carried out at 50-60°C for 1-3 hours. Sampling and detection of Disperse Yellow 54<0.5% is qualified. Then under the condition of this temperature, degas bromine for 0.5-1 hour. After the bromine removal was completed, the material was slowly transferred to a 1000ml four-necked flask into which 295g of clear water had been added for isolation for 0.5 to 1.5 hours. Then filter again, and the filter cake is transferred to a four-necked flask into which 500ml of clear water has been added for beating for 0.5 to 1 hour. Then filter, wash with 200 ml of clear water for four t...

Embodiment 2

[0024] Add 220g (2.2mol) of 98% sulfuric acid into a 500ml four-neck flask, and add 50g (0.173mol) of Disperse Yellow 54 under stirring, and heat up to 30-35°C with stirring; add 30.8g (0.38mol) of hydrobromic acid dropwise A total of 48g (1.0mol) of ozone was introduced for 1.5h, and the temperature was kept at 35-40°C for 1-2 hours. Then the temperature is raised to 60°C, and the reaction is kept at 60-75°C for 1-3 hours. Sampling and detection of Disperse Yellow 54<0.5% is qualified. Then under the condition of this temperature, degas bromine for 0.5-1 hour. After the bromine removal was completed, the material was slowly transferred to a 1000ml four-necked flask into which 405g of clear water had been added for isolation for 0.5 to 1.5 hours. Then filter again, and the filter cake is transferred to a four-necked flask into which 500ml of clear water has been added for beating for 0.5 to 1 hour. Then filter, wash with 200 ml of clear water for four times, and then suck d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com