Spiral evaporation device for green pepper chicken essence oil

An evaporating device and technology of chicken essence, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of large temperature difference in refining chicken fat, splashing of oil droplets, dark color of chicken oil, etc., so as to improve the actual use effect and prevent Cleanliness and improvement of refining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

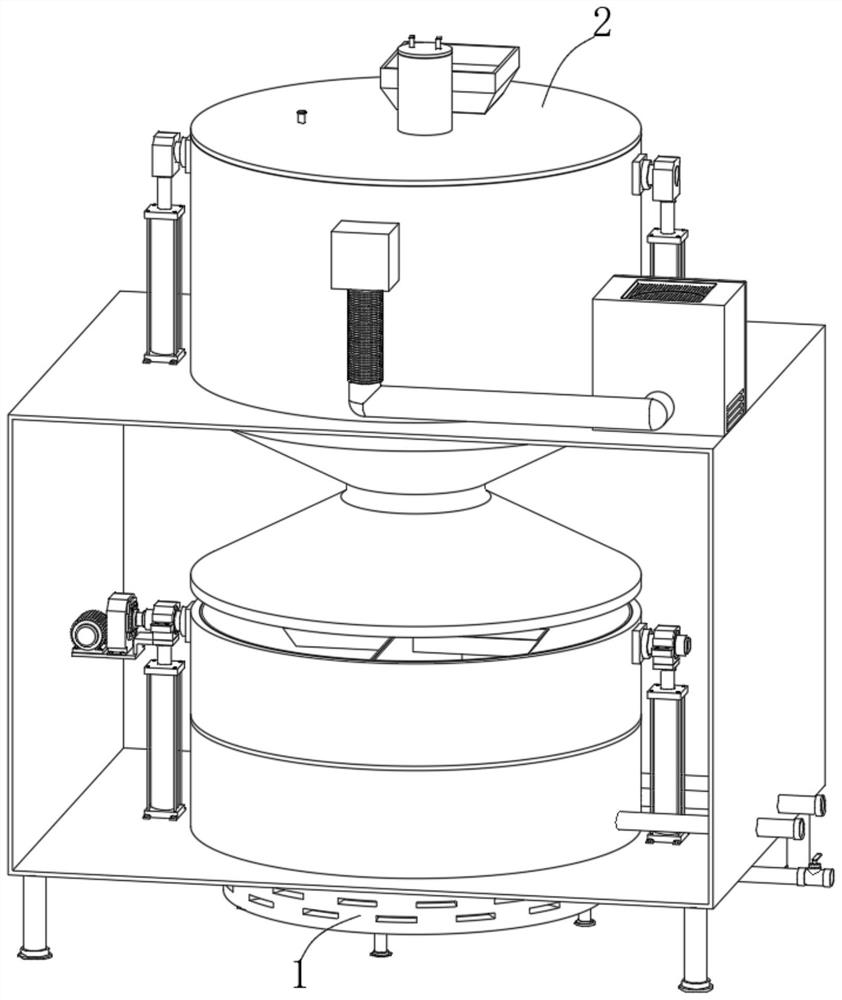

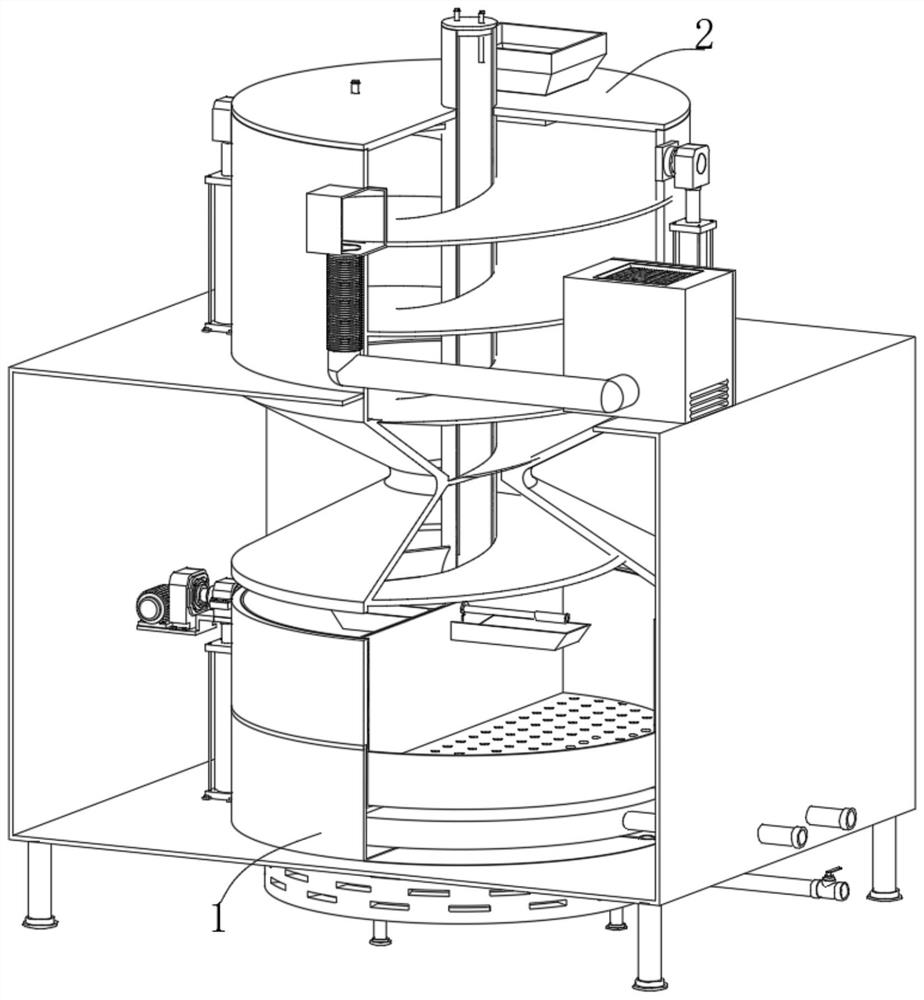

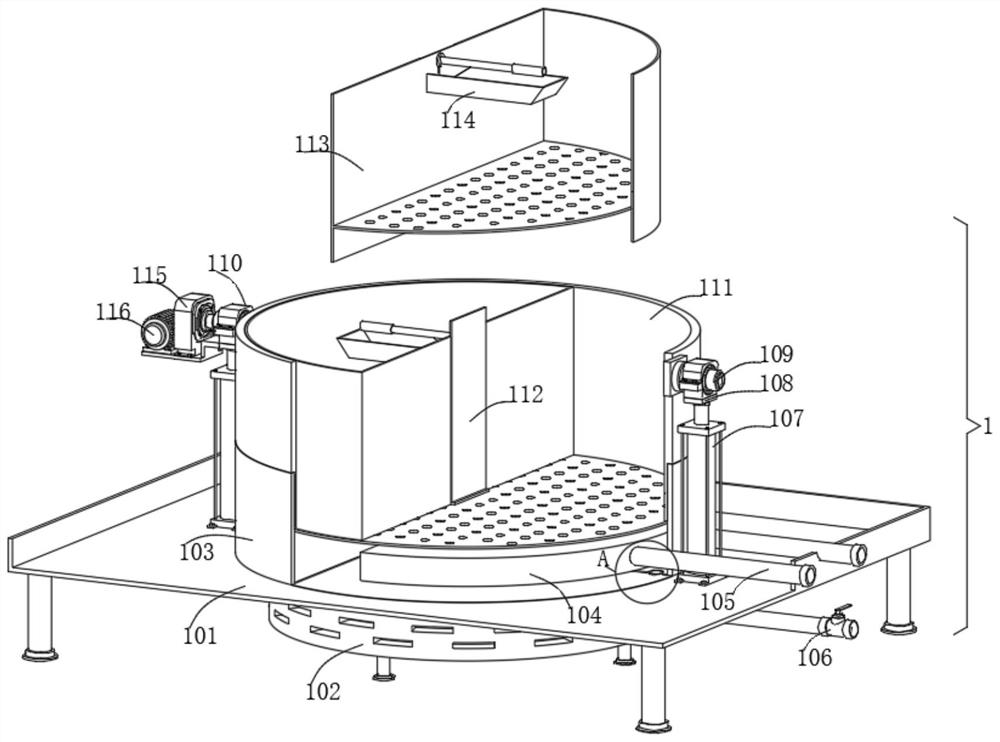

[0026] Embodiment one, with reference to Figure 1-7: A spiral evaporator for green pepper chicken refined oil, comprising an oil refining mechanism 1 and a screw mechanism 2, the screw mechanism 2 is arranged on the top of the oil refining mechanism 1, the oil refining mechanism 1 includes a bottom frame 101, and the setting of the bottom frame 101 provides the installation of other functional components of the equipment Foundation, the center of the bottom of the bottom frame 101 is provided with an installation opening, the establishment of the installation opening is convenient for the installation and setting of the electric heating base 102, and the electric heating base 102 is embedded inside the installation opening, and the establishment of the electric heating base 102 can effectively provide chicken fat refining. The temperature required for manufacturing, the structure and principle of the electric heating base 102 belong to the prior art, and for the sake of omitti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap