A process and device for recovering butanone by pervaporation

A technology of recovering butanone and pervaporation, which is applied in the chemical industry, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high energy consumption for separation, and achieve the effect of good recycling and small processing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

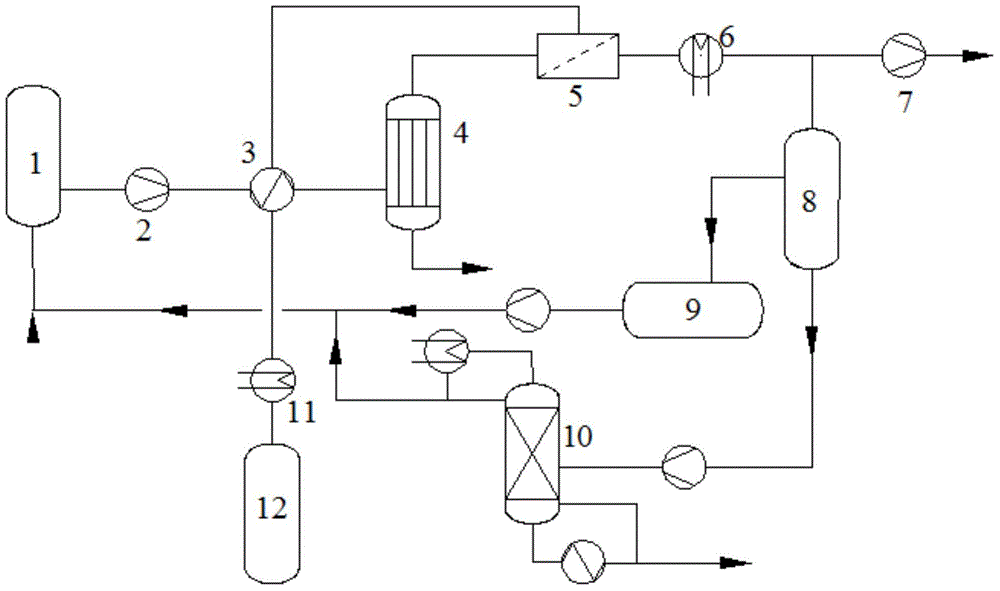

[0030] A kind of technology that pervaporation method reclaims butanone, comprises the following steps: the butanone raw material liquid that will be stored in raw material storage tank 1 and comes from reaction procedure, control flow rate is that 500kg / h is delivered to preheater 3, pass product steam to this The feed liquid is preheated to 70°C, and then enters the evaporator 4 for heating. The feed liquid is heated to 110°C and enters in the form of steam into 5 NaA molecular sieve membrane modules (each membrane module has an area of 7m 2 ) pervaporation membrane separation unit 5 formed in series for dehydration and separation. The pressure on the feed liquid side is 0.2MPa, and the pressure on the permeate side is controlled at 1000Pa. The water content of the feed liquid is concentrated and reduced to 0.1% through membrane separation, the feed liquid flows through the preheater 3 to preheat the feed liquid, and then condenses through the product condenser 11 and ente...

Embodiment 2

[0032] A kind of technology that pervaporation method reclaims methyl ethyl ketone, comprises the following steps: will be stored in raw material storage tank 1 and come from the methyl ethyl ketone raw material liquid of reaction procedure, control flow rate is 500kg / h and transport to preheater 3, pass finished product to the material The feed liquid is preheated to 60°C, and then enters the evaporator 4 for further heating. After the feed liquid is heated to 100°C, it enters into 8 PVA membrane modules (the area of each membrane module is 8m 2 ) permeable membrane separation unit 5 formed in series for dehydration and separation. The pressure on the feed liquid side is 0.3MPa, and the pressure on the permeate side is controlled at 500Pa. The water content of the feed liquid is concentrated to 0.05% through membrane separation, and the feed liquid flows through the preheater 3 to preheat the feed liquid and then enters the product tank 12 through the product condenser 11 ....

Embodiment 3

[0034]A kind of technology that pervaporation method reclaims butanone, comprises the following steps: the butanone raw material liquid that will be stored in the raw material storage tank 1 and come from reaction process, control flow rate is that 800kg / h is sent to preheater 3, pass product steam to this The feed liquid is preheated to 75°C, and then enters the evaporator 4 for heating. The feed liquid is heated to 135°C and enters in the form of steam into 9 NaA molecular sieve membrane modules (each membrane module has an area of 8m 2 ) permeable membrane separation unit 5 formed in series for dehydration and separation. The pressure on the feed liquid side is 0.5MPa, and the pressure on the permeate side is controlled at 300Pa. The water content of the feed liquid is concentrated to 0.01% through membrane separation, and the feed liquid flows through the preheater 3 to preheat the feed liquid and then enters the product tank 12 through the product condenser 11. The wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap