A kind of preparation method of rare earth magnesium alloy composite material

A composite material, a technology of rare earth magnesium, applied in the field of preparation of rare earth magnesium alloy composite materials, can solve the problems of failure to achieve dispersion strengthening, particle agglomeration, etc., and achieve the effect of improving surface wettability, improving wettability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

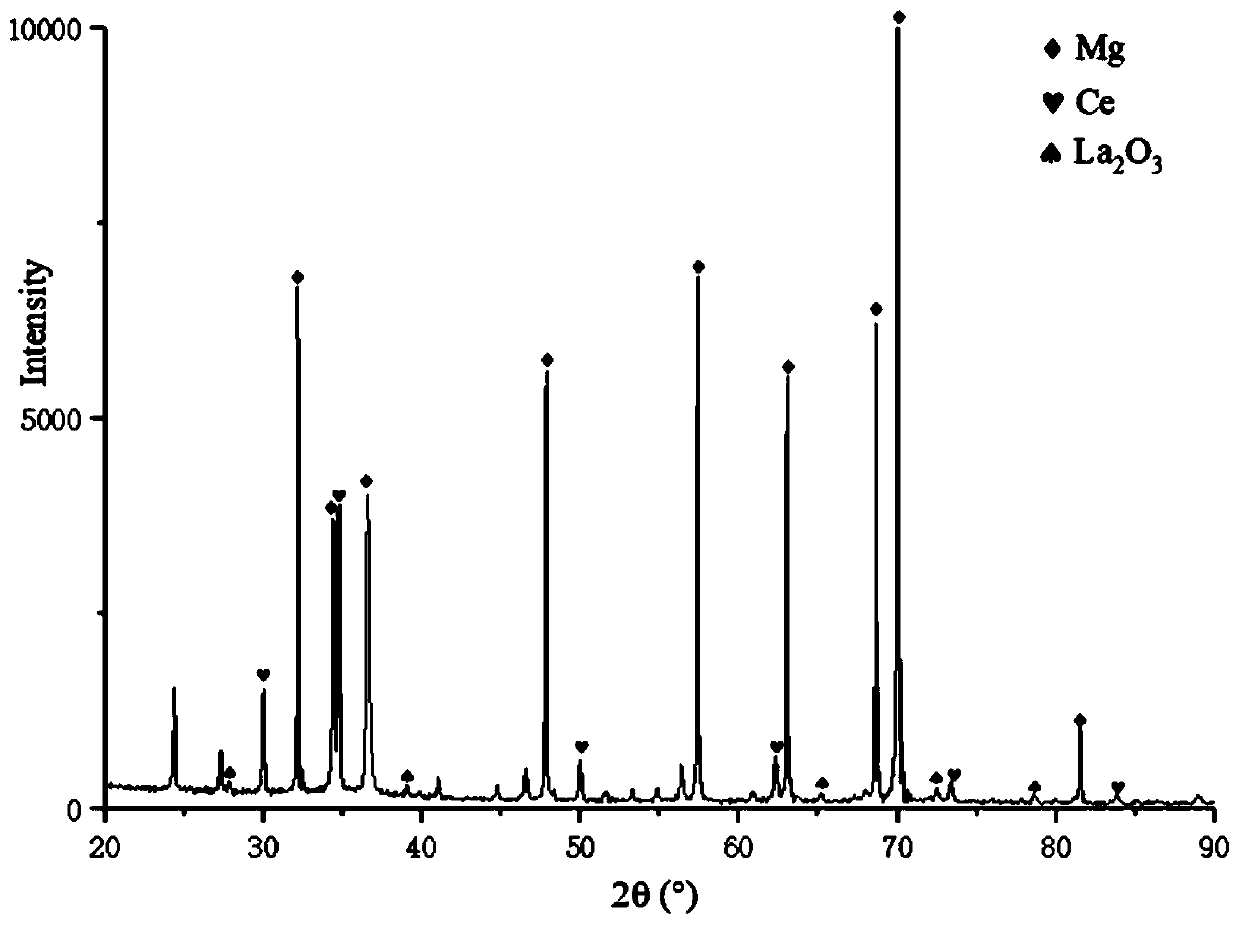

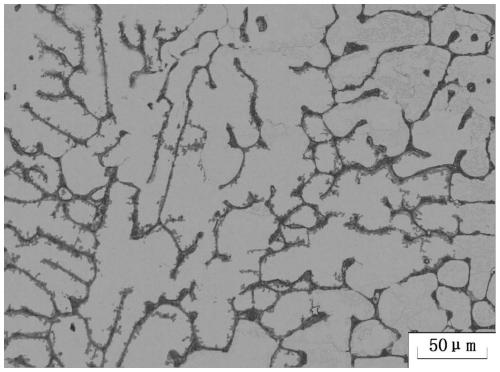

Embodiment 1

[0046] (1) Prepare magnesium ingot as raw material; prepare rare earth magnesium master alloy Mg-Ce alloy; prepare salt flux and reinforcement; salt flux is CeCl 4 ; Reinforcement is rare earth oxide La 2 o 3 Particles; the reinforcement is 2% of the total volume of the raw material; the reinforcement is 5% of the total volume of the salt flux; the mass percentage of rare earth Ce in the rare earth magnesium master alloy and the magnesium ingot is 5%;

[0047] (2) Put the salt flux in a clay crucible, heat it to 773K to make a salt flux melt; add the reinforcement to the salt flux melt, stir to disperse the reinforcement evenly, and make a liquid-solid mixture; stirring speed 150r / min, time 2min; when the reinforcement is added to the salt flux melt, all the reinforcement is added in 3 times, and the amount added each time is less than 50% of the total weight of the reinforcement;

[0048] (3) Pour the liquid-solid mixture into a clay crucible at room temperature, and cool ...

Embodiment 2

[0055] Method is with embodiment 1, and difference is:

[0056] (1) The rare earth magnesium master alloy is Mg-Y alloy; the salt flux is YCl 3 ; Reinforcement is boride ZrB 2 ,;

[0057] (2) The reinforcing body is 0.5% of the total volume of the raw material; the reinforcing body is 1% of the total volume of the salt flux; the mass percentage of the rare earth Y in the rare earth magnesium master alloy and the magnesium ingot is 3%;

[0058] (3) Put the salt flux in a graphite crucible and heat it to 803K to make a salt flux melt; the stirring speed is 140r / min, and the time is 4min; when the reinforcement is added to the salt flux melt, all reinforcements are divided into 4 times join in;

[0059] (4) Pour the liquid-solid mixture into a graphite crucible at normal temperature for cooling;

[0060] (5) Stir after raw material and rare earth magnesium master alloy are melted at 953K;

[0061] (6) After stirring, heat up to 983K and let it stand for 25 minutes; the stirr...

Embodiment 3

[0064] Method is with embodiment 1, and difference is:

[0065] (1) Prepare magnesium ingots and other metal components as raw materials, and other metal components are aluminum ingots and zinc ingots, and aluminum and zinc account for 2% and 3% of the total mass of raw materials respectively; the rare earth magnesium master alloy is Mg-La alloy; the salt flux is LaCl 3 ; The reinforcement is elemental metal Ni;

[0066] (2) The reinforcing body is 30% of the total volume of the raw material; the reinforcing body is 50% of the total volume of the salt flux; the mass percentage of the rare earth La in the rare earth magnesium master alloy and the magnesium ingot is 9%;

[0067] (3) Put the salt flux in a graphite crucible and heat it to 833K to make a salt flux melt; the stirring speed is 130r / min, and the time is 8min; when the reinforcement is added to the salt flux melt, all reinforcements are divided into 5 times join in;

[0068] (4) Pour the liquid-solid mixture into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap