A high-sensitivity impact-triggered supersonic warhead fuze

A high-sensitivity, supersonic technology, applied in the field of fuzes, can solve the problem that the sensitivity is difficult to meet such requirements, and achieve the effects of improving intrinsic safety, increasing sensitivity and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

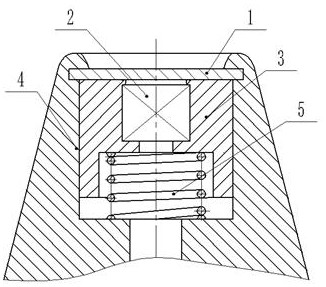

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, a high-sensitivity impact-triggered supersonic warhead fuze is based on the existing supersonic warhead fuze, a sliding seat 3 and a spring 5 are added to the head cavity of the fuse body 4, and the existing supersonic warhead fuze is added. The collision explosive element 2 in the warhead fuze is moved up to the sliding seat 3, the sliding seat 3 and the head cavity are in clearance fit, and the top surface of the sliding seat 3 is close to the cover foil in the existing supersonic warhead fuze 1 bottom surface, so that the collision and explosion element 2 is close to the cover foil 1, the sliding seat 3 is cylindrical, and there are two-stage through holes along its axial direction. The diameter of the first-order hole is larger than that of the second-order hole, and the collision explosion element 2 is fixed in the first-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com